Appendix A. The diffusion coefficient of progesterone in the release

advertisement

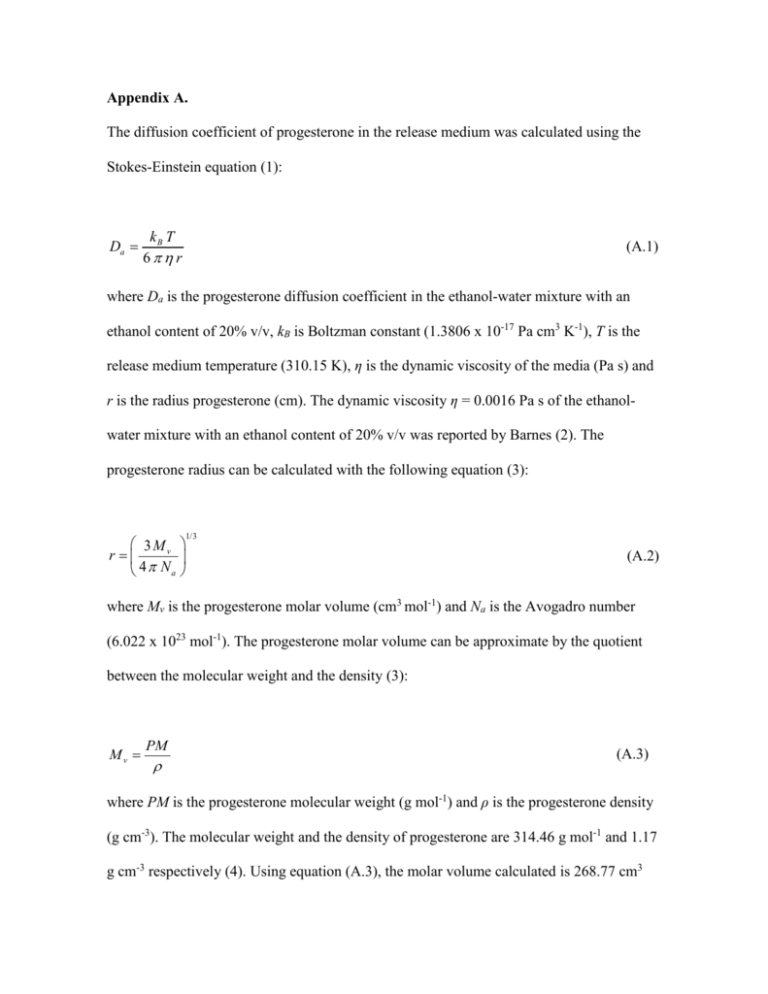

Appendix A. The diffusion coefficient of progesterone in the release medium was calculated using the Stokes-Einstein equation (1): Da kB T 6 r (A.1) where Da is the progesterone diffusion coefficient in the ethanol-water mixture with an ethanol content of 20% v/v, kB is Boltzman constant (1.3806 x 10-17 Pa cm3 K-1), T is the release medium temperature (310.15 K), η is the dynamic viscosity of the media (Pa s) and r is the radius progesterone (cm). The dynamic viscosity η = 0.0016 Pa s of the ethanolwater mixture with an ethanol content of 20% v/v was reported by Barnes (2). The progesterone radius can be calculated with the following equation (3): 1/3 3Mv r 4 Na (A.2) where Mv is the progesterone molar volume (cm3 mol-1) and Na is the Avogadro number (6.022 x 1023 mol-1). The progesterone molar volume can be approximate by the quotient between the molecular weight and the density (3): Mv PM (A.3) where PM is the progesterone molecular weight (g mol-1) and ρ is the progesterone density (g cm-3). The molecular weight and the density of progesterone are 314.46 g mol-1 and 1.17 g cm-3 respectively (4). Using equation (A.3), the molar volume calculated is 268.77 cm3 mol-1. Introducing this value in equation (A.2), the progesterone radius is r = 4.7 x 10-8 cm. Finally, using equation (A.1), a progesterone diffusion coefficient Da = 3.02 x 10-6 cm2 s-1 was calculated. The effective thickness of the stagnant liquid layer was calculated employing the Levich equation (5): ha 1.62 Da1/3 1/6 1/2 (A.4) where ha is the effective thickness of the stagnant liquid layer (cm), is the cinematic viscosity of the release medium (cm2 s-1) and ω is the rotation angular velocity of the release device (s-1). The Levich equation allows to calculate the effective thickness of the stagnant liquid layer existing on the surface of a device that rotate at constant velocity (5). The cinematic viscosity of the ethanol-water mixture with a ethanol content of 20% v/v can be calculated using the dynamic viscosity value, as follows: m (A.5) where ρm is the density of the ethanol-water mixture with a ethanol content of 20% v/v (g cm-3). Using the dynamic viscosity of the ethanol-water 20:80, ρm = 0.9616g cm-3, the cinematic viscosity was calculated resulting in = 0.0166 cm2 s-1. The rotation angular velocity of the device can be calculated as: 2 f 60 (A.6) where f is the revolutions per minute (min-1). The values of ω obtained for stirring speed of 25 rpm and 100 rpm are 2.6180 s-1 and 10.4720 s-1, respectively. Consequently, using equation (A.4), the effective thickness of the stagnant liquid layer is 0.0073 cm and 0.0036 cm for stirring speed of 25 rpm and 100 rpm, respectively. References 1. Bird RB, Stewart WE, Lightfoot EN. Fenómenos de transporte: un estudio sistemático de los fundamentos del transporte de materia, energía y cantidad de movimiento. Barcelona, España: Ed. Reverté; 1995. 2. Barnes HA. A handbook of elementary rheology. Aberystwyth, Wales: Cambrian Printers; 2000. 3. Amidon GL, Lee PI, Topp EM. Transport processes in pharmaceutical systems. New York, USA: Marcel Dekker Inc.; 2000. 4. Sigma-Aldrich. Safety data sheet of Progesterone. Safety data sheet. 2010. 5. Chien YW. Fundamentals of controlled-release drug administration. Swarbrick J, editor. New York and Basel: Marcel Dekker Inc.; 1982.