The Detection of Gasoline as an Ignitable Liquid: Measuring Error

advertisement

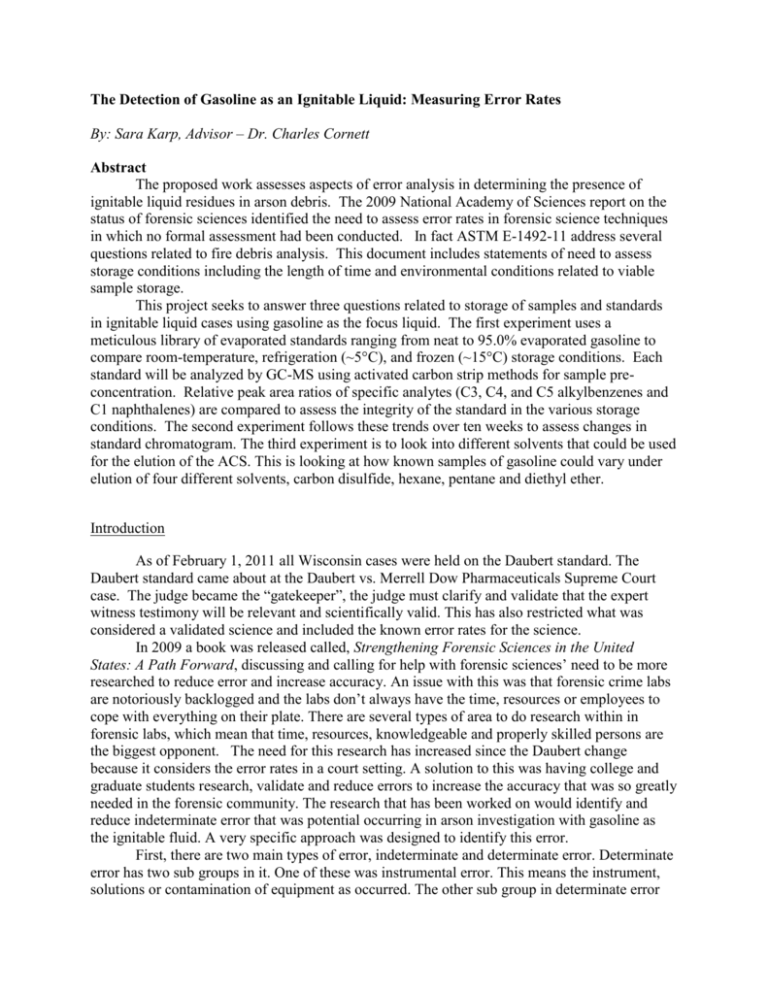

The Detection of Gasoline as an Ignitable Liquid: Measuring Error Rates By: Sara Karp, Advisor – Dr. Charles Cornett Abstract The proposed work assesses aspects of error analysis in determining the presence of ignitable liquid residues in arson debris. The 2009 National Academy of Sciences report on the status of forensic sciences identified the need to assess error rates in forensic science techniques in which no formal assessment had been conducted. In fact ASTM E-1492-11 address several questions related to fire debris analysis. This document includes statements of need to assess storage conditions including the length of time and environmental conditions related to viable sample storage. This project seeks to answer three questions related to storage of samples and standards in ignitable liquid cases using gasoline as the focus liquid. The first experiment uses a meticulous library of evaporated standards ranging from neat to 95.0% evaporated gasoline to compare room-temperature, refrigeration (~5°C), and frozen (~15°C) storage conditions. Each standard will be analyzed by GC-MS using activated carbon strip methods for sample preconcentration. Relative peak area ratios of specific analytes (C3, C4, and C5 alkylbenzenes and C1 naphthalenes) are compared to assess the integrity of the standard in the various storage conditions. The second experiment follows these trends over ten weeks to assess changes in standard chromatogram. The third experiment is to look into different solvents that could be used for the elution of the ACS. This is looking at how known samples of gasoline could vary under elution of four different solvents, carbon disulfide, hexane, pentane and diethyl ether. Introduction As of February 1, 2011 all Wisconsin cases were held on the Daubert standard. The Daubert standard came about at the Daubert vs. Merrell Dow Pharmaceuticals Supreme Court case. The judge became the “gatekeeper”, the judge must clarify and validate that the expert witness testimony will be relevant and scientifically valid. This has also restricted what was considered a validated science and included the known error rates for the science. In 2009 a book was released called, Strengthening Forensic Sciences in the United States: A Path Forward, discussing and calling for help with forensic sciences’ need to be more researched to reduce error and increase accuracy. An issue with this was that forensic crime labs are notoriously backlogged and the labs don’t always have the time, resources or employees to cope with everything on their plate. There are several types of area to do research within in forensic labs, which mean that time, resources, knowledgeable and properly skilled persons are the biggest opponent. The need for this research has increased since the Daubert change because it considers the error rates in a court setting. A solution to this was having college and graduate students research, validate and reduce errors to increase the accuracy that was so greatly needed in the forensic community. The research that has been worked on would identify and reduce indeterminate error that was potential occurring in arson investigation with gasoline as the ignitable fluid. A very specific approach was designed to identify this error. First, there are two main types of error, indeterminate and determinate error. Determinate error has two sub groups in it. One of these was instrumental error. This means the instrument, solutions or contamination of equipment as occurred. The other sub group in determinate error was that you yourself have made a mistake, as in spilling a solution or not following procedure. Indeterminate error on the other hand was random errors happening or errors happening with reason unknown to us currently. This research would be going after the very precise error, indeterminate error. This was the most difficult error to identify for several reasons. The two main reasons are that it was unknown what was causing the error and there was no control over it occurring. This experiment was only looking at indeterminate error because determinate error was continuously being tested for and corrected. All experiments can have a chance for indeterminate error. Though if the error can be found, then it can possibly be reduced and increase the accuracy and support crime lab chemists in a court setting. In order to insure that the same procedure, the proper use of instruments and guild lines as they would in any forensic lab, ASTM reports were used. These ASTM reports are standard internationally followed experimental procedures and guidelines for several areas of chemistry including forensic science, and even specifically arson investigation and addresses gasoline as the ignitable liquid in arson investigations. These reports have helped to develop the procedure. These reports show that the instrumentation that was most commonly used was gas chromatography- mass spectrometer (GC-MS). The two procedures most commonly used to identify that gasoline was used in a suspected arson case are an activated carbon/charcoal strip (ACS) passive headspace and solid phase microextraction (SPME) passive headspace. A GC-MS are two instruments hooked up together to give a more accurate and informative result. The GC part was a gas chromatography instrument. This was an instrument that has an injector point, leading into the main unit of the GC which was an oven with a long looping very thin column that has a stream of gas, generally helium (He) flowing through it. The oven slowly heats to a maximum temperature of 300°C as the compound was traveling through it. At the end there was a detector. The compound was heated into a gaseous state and ends up separating itself out as it travels through the column. Based on how quickly the different components of the compound vaporize and travel through the column gives the information wanted. After this component the particles get hit with a large amount of electrons to ionize them. In order to get through a filter into the next component of the MS the components must be charged. There they are introduced to an electromagnetic field. This was a set up of several magnets that spin causing the components to spin and fragment. The fragments are still charged and travel to a detector that reads their charge and from there they can be identified by mass. All of this data was then sent to a computer in the form of graphs. This yields the knowledge of what exactly was in a compound and how much of each part makes up that compound. This can be specific enough to even allow us to see how degraded gasoline was from being the ignitable liquid. The main parts of gasoline what are tracked in the evaporation of gasoline are toluene, naphthalene, aromatic rings, cycloparaffin and alkenes. The compounds all have different volatile states. So we could specifically say that this gasoline was 50% evaporated or degraded, by tracking these components. Fire or extreme heat can speed up the evaporation of these components. The first step of the project was to make a new library of gasoline evaporation data. This was because the libraries of gasoline evaporation all show it set at the same specific rates 0%, 25%, 50%, 75%, 90%, 95% and 98-99%. What was desired was to see what exactly happens to the gasoline between these percents. When exactly compounds are starting to be evaporated out, how quickly and does it change the look of other parts of the compound? This was a library that was used to compare all of our other results too. Our main area of potential indeterminate error was found in an ASTM report, specifically the ASTM report E2451 – 08. This stated that: “The changes that occur under various storage conditions have not been fully documented.” and that: “Changes to preserved sample extract and the length of time it remains viable under storage conditions is unknown.” as well as: “Preserved samples and extracts may be stored at room temperature, under refrigeration, or frozen. Effects of temperature and freeze-thaw conditions on the stability and viability of samples, effectiveness of container sealing and the container integrity are factors to be considered in the selection to thermal storage conditions.” The defense attorney can use Daubert on any arson investigation case where any sample was stored and had to be retested for any reason, throwing out possibly a main part of physical evidence from the case. This gives a larger area of unknowns and errors to find and fix. So the previous experiments samples made will be stored under the different storing conditions for various amounts of time and then retested and compared. The other area of testing wanted was in the GC-MS area. Stated earlier was that GC-Ms tends to be He based but He is a non renewable resource. There is a shortage of He and scientists are trying to stop using it as often as they do in experiments. The idea was to switch to hydrogen (H2) gas instead in a GC-MS but the effects of switching to this for arson investigation samples in unknown but will be tested during this research. Methods and Materials The same GC-MS was used throughout the experiments. This GC-MS was a 5890 Series II gas-chromatography model number 5972A and a S/N 3329A00595 Hewlett Packard Series II 5890 attached to a MS 5972 Series Mass Selective Detector. Library: Gasoline was purchased; it was no ethanol gasoline 87-octane regular from B&B Services that gets new gasoline everyday from a Madison, WI supplier. The gas was bought on November 11, 2012, this date was important because gasoline additives change depending on the season. This gasoline was placed in the ASTM standard vial with polytetrafluoroethylene (PTFE, basically Teflon) lined seals, Supelco 40mL clear vial, screw cap, hole cap with PTFE/Silicone septa. A METTLER TOLEDO PG-12001-S was brought into the lab and calibrated to maintain accuracy of the weights and a METTLER TOLEDO PG203-S max 210g d=0.001g and automatic calibration was used. The assumption that was made was that 1g was approximately equal to 1mL. Storage: Standard Supelco 40mL clear vial, screw cap, hole cap with PTFE/Silicone septa were used for the storage of standards. A common refrigerator with freezer was used. Solvents: Four solvents were used and tested for this portion of the experiment. These solvents were, Hexanes; UW-Platteville Chemistry Stock Room, UW-Platteville Hazardous Material 509892 Carbon disulfide; UW-Platteville Chemistry Stock Room Pentane; UW-Platteville Chemistry Stock Room, UW-Platteville Hazardous Material 509600 Diethyl ether; UW-Platteville Chemistry Stock Room, UW-Platteville Hazardous Material 511762 from Fisher Chemical 1552 M-6514 Dr. Chuck Cornett provided standard ACS from Albrayco Technologies Inc. and one gallon sterol paint can. The oven that was used was a Fisher Scientific, UW-Platteville Capital 104225. KIMTECH science Kimwipes were used for a matrix. Procedure Forty samples each of 20.0g of the gasoline were made and labeled the same day as the purchase. These samples were to be run under nitrogen gas evaporation. Since nitrogen was heaver on its own then our atmosphere it was the only thing causing the evaporation on the gasoline and was evaporating in the same way but at a faster rate than it would if it was just sitting at ambient temperatures. Once the samples were made they were sent though a GC-MS. Experiment The samples were evaporated down in 2.5% increments until 95.0% evaporation was reached. It was considered for this that evaporation and weight corresponded. So to evaporate a sample down by 2.5% the sample stayed under a nitrogen flow until its weight dropped down by 2.5%. Gloves were worn during the evaporation process to prevent the weight gain from finger prints on the vials. A second smaller grouping of evaporations were done as well, in order to determine whether the data from the first group could be replicated and to help in comparisons. This smaller grouping was done at 50.0%, 75.0%, 90.0%, 95.0% and 99.0%. These percentages are the current common standard evaporation you would find in a crime lab. solvent, carbon disulfide, pentane, hexane and diethyl ether, to use as blanks. Another four were prepared labeled ACS and a solvent. The can was opened in a hood and the ACSs were removed while wearing gloves and placed into an ACS labeled vial. Each vial got approximately 1mL of a solvent. In the end there should be a blank vial for carbon disulfide, hexane, pentane and diethyl ether. As well as four vials with ACS in them and each eluted by a different solvent. These vials were then put through a GC-MS. A second set passive head set was made the same as above but this one was place in the over at 80°C for 16 hours instead. This was done to see if the results could be replicated and to see if the results would be ratio skewed and favoring as well. Results 300000 250000 200000 150000 100000 50000 0 Alkane Trend Lines Point of intersection: 63.83 Toluene Trend Lines Point of Intersection: 64.345 400000 Abundance Abundance Library: 300000 200000 100000 0 0 50 0 100 Percent Evaporated 150000 100000 50000 600000 Abundance Intersection: 77.76 Abundance 100 m/p-xylene Trend Line Ethylbezene Trend Line Point of 250000 200000 50 Percent Evaporated 400000 200000 0 0 0 50 Percent Evaporated 100 0 50 Percent Evaporated 100 m/p-ethyltoluene Point of Trend Lines Intersection: 300000 350000 300000 250000 200000 150000 100000 50000 0 Point of Intersection: 81.18 Abundance 84.55 50 Percent Evaporated Abundance intersection: 85.91 500000 0 200000 50 Percent Evaporated Point of Intresection: 87.07 100000 50000 0 0 50 Percent Evaporated 85.40 50 Percent Evaported 100 1,2,3-trimethylbenzene Trend Lines 140000 Abundance 150000 0 100 o-ethyltoluene Trend Point of Lines Intersection: 90000 100000 Point of intersection: 88.90 40000 50000 0 0 50 Percent Evaporated 100 Naphthalene Trend 150000 Lines Point of Intersection: 74.98 100000 50000 0 0 100 Trend Lines 1,3,5trimethylbenzene 150000 0 Abundance 100000 100 1,2,4-trimethylbenzene 1000000 Trend Lines Point of Abunance 200000 0 0 Abundance Abundance o-xylene Trend Lines 50 Percent Evaporated 100 -10000 0 50 Percent Evaporated 100 The data above statistically shows that the current standards are acceptable evaporations to use as standards in arson investigation where gasoline is the ignitable liquid, though when looking at relevant standard evaporations, 50.0% evaporation doesn’t necessarily need to be a standard. Discussion Relevant standards are defined for this paper as the evaporations that clearly show a change in the major components of gasoline’s disappearance. The abundance differences were not considered because that can vary for several reasons. There was no change that can be identified between 50.0% and 75.0%. There was a defined difference between 75.0% and 90.0%. The difference that could be seen here was the disappearances of alkane and toluene peaks. When it came to the ion extractions the peaks representing the branched and straight chain alkanes, toluene, cycloalkanes and cylcohexanes were lost. There was also a difference seen between 90.0% and 95.0%, the xylene group’s departure from the data with its corresponding ion extraction peaks. There was also a definite change between 95.0% and 99.0%. The change was the loss of the crown and 1,2,3trimethylbezene as well as the loss of any other compounds showing between 1,2,3trimethylbenzene and nine minutes of retentions. These compounds are mainly C3 and C4 alkylbenzenes and some C1 and C2 alkylbenzenes. Conclusion The conclusion that was made is that the relevant and statistically sound standard evaporations to use in arson investigation are 75.0%, 90.0%, 95.0% and 99.0%.