file - Bioresources and Bioprocessing

advertisement

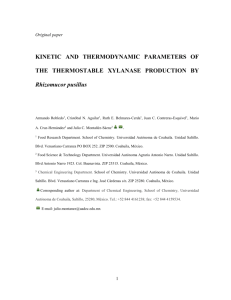

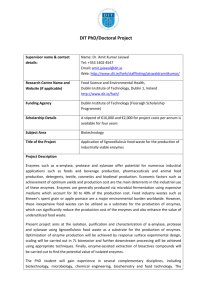

24 Additional file 1 Optimization of upstream and downstream process parameters for cellulase-poor-thermo-solvent-stable xylanase production and extraction by Aspergillus tubingensis FDHN1 Dharmesh N. Adhyaru1, Nikhil S. Bhatt1*, H.A. Modi2 1 2 P. G. Department of Microbiology, Gujarat Vidyapeeth, Sadra- 382 320, Gujarat, India Department of Life Sciences, School of Sciences, Gujarat University, Ahmadabad, Gujarat, India Corresponding author Dr. Nikhil S. Bhatt* P. G. Department of Microbiology, Gujarat Vidyapeeth, Sadra- 382 320, Gujarat, India. Contact No.: (M) +91 98794 83847, (O) 079- 23274274 Fax No.: (079) 232 74 272 E. Mail address: bhattnikhil2114@gmail.com 25 Table S1 Effect of metals and modulators on xylanase production from A. tubingensis FDHN1 under SSF Potential additives Xylanase activity (U/g) Protein (mg/g) Specific activity (U/mg) Cellulase activity (U/g) Control a Metal compounds CuCl2 MgCl2 SnCl2 CaCl2 HgCl2 CoCl2 MnCl2 NiCl2 FeCl3 1957 ± 17 27.22 ± 1.36 71.89 ± 2.98 3.12 ± 0.16 2239 ± 20 2446 ± 27 1597 ± 16 2179 ± 17 973.4 ± 14 1316 ± 28 2089 ± 20 1657 ± 24 2047 ± 14 29.07 ± 1.16 25.47 ± 0.99 24.11 ± 1.08 29.95 ± 0.53 26.65 ± 1.22 23.32 ± 0.64 26.81 ± 1.39 24.63 ± 0.75 26.30 ± 1.03 77.02 ± 3.48 96.03 ± 4.21 66.23 ± 3.13 72.75 ± 3.06 36.52 ± 1.44 56.43 ± 2.57 77.91 ± 3.87 67.27 ± 2.41 77.83 ±2.53 1.98 ± 0.10 3.45 ± 0.18 1.80 ± 0.05 2.56 ± 0.17 0.77 ± 0.13 1.54 ± 0.11 4.07 ± 0.14 3.42 ± 0.12 3.11 ± 0.16 2262 ± 19 2449 ± 23 1882 ± 20 2236 ± 9 2071 ± 33 1545 ± 18 1798 ± 30 25.14 ± 0.88 26.87 ± 0.43 15.71 ± 0.67 25.60 ± 1.09 24.15 ± 0.98 25.15 ± 1.12 20.32 ± 0.84 89.97 ± 3.86 91.14 ± 4.33 119.79 ± 4.97 87.34 ± 3.03 85.75 ± 3.12 61.43 ± 2.51 88.48 ± 4.24 3.48 ± 0.15 4.21 ± 0.13 2.70 ± 0.08 4.37 ± 0.17 3.66 ± 0.09 2.91 ± 0.19 2.85 ± 0.11 Modulators Tween-40 Tween-80 Triton X-100 Glycine Glycerol EDTA SDS a SSF was carried using 9 g sorghum straw under optimized physiological conditions (at 5 days incubation, 1:5 (w:v) substrate: moisture ratio, pH 6.0 and 40 °C). *The control medium used was devoid of any additives. The data presented are the mean values of three replicates with the standard deviations. 26 Figure S1 Effect of sorghum straw concentration (3 to 15 g) on xylanase production. SSF was carried out by moistening sorghum straw with mineral salt medium pH 5.0 at 35 °C for 6 days. Figure S2 Effect of xylose concentration (0.1 to 1.1 %) on xylanase production. SSF was carried using 9 g sorghum straw under optimized physiological conditions (at 5 days incubation, 1:5 (w:v) substrate: moisture ratio, pH 6.0 and 40 °C). Figure S3 Effect of organic solvents (10 to 30 %) on the xylanase activity. The crude xylanase was incubated in the presence of various organic solvents concentration for 30 min and at the end of reaction residual activities were measured. Figure S4 Comparison of the un-optimized and optimized extraction conditions on the xylanase recovery efficiency (%). Optimized extraction conditions were extractant/ solid ratio 12: 1 (v:w), 150 rpm agitation speed and 40 °C. The data presented are the mean values of three replicates with the standard deviations. 27 Protein Specific activity Cellulase activity 1600 80 1400 70 1200 60 1000 50 800 40 600 30 400 20 200 10 0 Protein (mg/g); Specific activity (U/mg); Cellulase activity (U/g) Xylanase activity (U/g) Xylanase activity 0 3 5 7 9 11 13 Sorghum straw concentration (g) 15 Figure S1 Protein Specific activity Cellulase activity Xylanase activity (U/g) 2500 100 90 80 70 60 50 40 30 20 10 0 2000 1500 1000 500 0 0.1 Figure S2 0.3 0.5 0.7 0.9 Xylose concentration (%) 1.1 Protein (mg/g); Specific activity (U/mg); Cellulase activity (U/g) Xylanase activity 28 Relative activity (%) 100 80 60 10% 40 20% 20 30% 0 Organic solvent Figure S3 Xylanase recovery efficiency (%) Unoptimized xylanase recovery Optimized xylanase recovery 100 90 80 70 60 50 40 30 20 10 0 30 Figure S4 60 90 120 Extraction time (min) 150