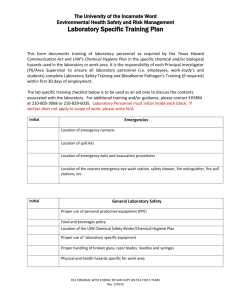

Chemical Hygiene Plan Template for Schools. Review completed by

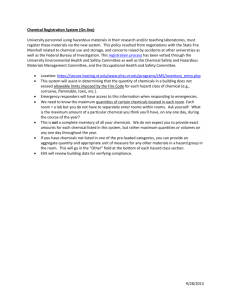

advertisement