In recent times, lightweight furniture construction has certainly not

advertisement

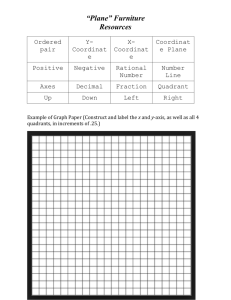

PRESS RELEASE November 2012 Page 1 Invest in the future today Lightweight furniture construction with igeL at ZOW 2013 The construction of lightweight furniture provides future-oriented stimulus along the entire process chain for the furniture industry and interior design. In demand is intelligent engineering that links innovative material concepts with new functionalities – thereby providing significant added value in furniture making. At the supplier trade fair ZOW in Bad Salzuflen, innovations in lightweight furniture construction have been presented to a broad trade audience since 2009. In 2013, the members of Press contact: Dr. Frank B. Müller PH MEYER Wirtschaftsberatung GmbH & Co. KG Telephone: +49 521 9653336 Fax: +49 521 96533-11 E-mail: fm@phmeyer.de Download: www.phmeyer.de Press database Text code: zdne1305 the Interessengemeinschaft Leichtbau e.V. – igeL (www.igel-ev.net) [German Lightweight Construction Interest Group] will present their special material and process expertise at the igeL Forum in Hall 22.1. Here, from 18-21 February, potential customers will be able to inform themselves first-hand. In recent times, lightweight furniture construction has certainly not had it easy. Now as before, there is a lot of discussion in the industry about lightweight construction; there has been progress in technological development and the group of users continues to expand. Nevertheless, the process of penetrating the market is much slower than many people have hoped. Is lightweight construction just a fashion trend? No, according to the pioneers in the Interessengemeinschaft Leichtbau e. V. – igeL. Meanwhile numbering over 100, igeL stakeholders, who in their industry network cover the entire value chain, further set their sights on continuous growth. For them, the breakthrough of lightweight furniture construction is only a matter of time. Hybrid designs at the fore The use of lightweight construction in furniture has already been anticipated in many respects: special machines, special drilling and milling tools, new Homepage ZOW: PRESS RELEASE November 2012 Page 2 edging technologies and fittings systems have been developed; usage details and proposed standards formulated. Suitable lightweight and sandwich materials have already made their mark in furniture construction where there is a cost advantage or added value for the end customer, retail or logistics. In practice, it is frequently hybrid designs that allow entry into lightweight construction. The much-cited strengths of lightweight construction cannot simply be dismissed. Whether less raw material input and thus reduced raw material costs, improved furniture logistics, new design concepts and functionalities or the ecological benefits – in the trade-off between cost savings and customer- Press contact: Dr. Frank B. Müller PH MEYER Wirtschaftsberatung GmbH & Co. KG Telephone: +49 521 9653336 Fax: +49 521 96533-11 E-mail: fm@phmeyer.de Download: www.phmeyer.de Press database Text code: zdne1305 specific added value, lightweight construction offers new opportunities for furniture producers and retailers to seize a competitive advantage. The furniture industry is watching current developments carefully, however it is extremely reticent when it comes to application. For as with other innovative technologies, there are also risks for companies with the use of lightweight construction concepts. In addition to worries about process reliability, investment costs and the acceptance of products by customers, the use of new materials and designs requires rethinking and learning in a company's product development and production departments. As a producer it is necessary to rise to this challenge in order to realise the potential of lightweight construction. Setting a timely course for the future If you ask experts like Prof. Torsten Leps, Director of the Central Laboratory for Material Testing at Rosenheim University of Applied Sciences, there are very good reasons for focusing on lightweight furniture construction now, weighing its advantages and disadvantages for a particular company and perhaps reconsidering the company's future course. One aspect is the looming shortage of resources for primary products for board materials: "If the predictions about the upcoming shortage of resources are true, the prices for particle board and fibreboard will no longer be tenable", according to Leps. Homepage ZOW: PRESS RELEASE November 2012 Page 3 "We must equip ourselves for the future and gather knowledge early on about the use of new, resource-sparing materials in the industry." At the same time, companies must accumulate expertise, says his Rosenheim colleague, Prof. Thorsten Ober, Director of the Laboratory for Furniture Technology and a founding member of igeL: "For production in the furniture industry it is important to keep checking when and for which furniture components the use of lightweight construction and sandwich materials make economic sense. In product development, it is becoming ever more important to exploit optimally the advantages of the new, different products in order to generate better service for retail and end customers." Ober is Press contact: Dr. Frank B. Müller PH MEYER Wirtschaftsberatung GmbH & Co. KG Telephone: +49 521 9653336 Fax: +49 521 96533-11 E-mail: fm@phmeyer.de Download: www.phmeyer.de Press database Text code: zdne1305 concerned that too hesitant a response could present an entrepreneurial risk: "The timely introduction of the topic of lightweight construction is a longterm investment in the sustainability of the company. The companies that will succeed tomorrow are beginning to focus intensively today on the effective use of materials and modern construction methods." New impulses: the igeL network at ZOW For furniture producers, igeL's extensive network is the central source of information and exchange, explains igeL Managing Director Dr. Olaf Plümer: "In the igeL network, manufacturers can get advice first-hand from materials experts at universities, from suppliers for production materials and from plant and machinery manufacturers. All of these people have the necessary knowledge and practical experience. Technically a lot is possible in lightweight furniture construction even today. However mastering the process is the challenge." Anyone who wants to know more about lightweight furniture construction and has concrete questions about materials and processes can speak with many igeL members in person at ZOW. The igeL Forum in Hall 22.1 is open to all interested parties. For current information about ZOW, visit: Web: www.zow.de Youtube: ZOWfair Twitter English: @zow_trade_fair Homepage ZOW: PRESS RELEASE November 2012 Page 4 Xing event: ZOW Bad Salzuflen 2013 LinkedIn event: ZOW Bad Salzuflen 2013 Figures: zdne1305_b1: Press contact: Dr. Frank B. Müller PH MEYER Wirtschaftsberatung GmbH & Co. KG Telephone: +49 521 9653336 Fax: +49 521 96533-11 E-mail: fm@phmeyer.de Download: www.phmeyer.de Press database Text code: zdne1305 Homepage ZOW: Here's where to go to learn more about lightweight furniture construction! In 2013, igeL will present itself at ZOW with its own forum in Hall 22.1. – Photo: Clarion Events zdne1305_b2: Suitable lightweight and sandwich materials have already made their mark in furniture construction. – Photo: Clarion Events Clarion Events Deutschland GmbH Clarion Events Deutschland GmbH, Bielefeld, is a wholly owned subsidiary of Clarion Events Ltd., London. Since starting up in Germany in 2010, it has organised the annual ZOW fair (Supply Fair for Furniture Industry & Interior Design) as well as the FMB show (Supplier Show for Mechanical Engineering) in Bad Salzuflen. Together PRESS RELEASE November 2012 Page 5 with its own Clarion Events TR subsidiary, it organises the ZOW fair in Istanbul. Clarion also cooperates with a Russian licensee for the ZOW fair in Moscow. As part of its portfolio, the company aims to set up further specialist fairs and congresses with a view to highlighting its added value from spot-on service for the business circles addressed. Clarion Events Deutschland GmbH’s Managing Directors are Simon Kimble and Mike Sicely, London, as well as Horst Rudolph, Bielefeld. Press contact: Dr. Frank B. Müller PH MEYER Wirtschaftsberatung GmbH & Co. KG Telephone: +49 521 9653336 Fax: +49 521 96533-11 E-mail: fm@phmeyer.de Download: www.phmeyer.de Press database Text code: zdne1305 Homepage ZOW: