mmc manual - St. Aloysius Institute of Technology, Jabalpur

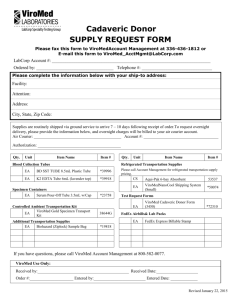

advertisement

ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) MECHANICAL MEASUREMENT & CONTROL LAB MANUAL V SEM ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) LIST OF EXPERIMENTS 1. Study of temperature measurement devices, Resistance Thermometer Detector (RTD). 2. Study of velocity of fluid flow by Venturimeter. 3. Study of velocity of fluid flow by Orificemeter. 4. Study of velocity of fluid flow by Pitot Tube. 5. Study construction and working of Bourdon Tube Pressure Gauge. 6. Study of sensitivity of Thermocouple. 7. Study of ‘Liquid in glass tube’ (Thermometer.) apparatus. ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) Experiment No.1 OBJECT: Study of temperature measurement devices (RTD) APPARATUS REQUIRED: Thermometer, DPM, RTD, Connecting wire, heater etc. THEORY: The thermometer, consists of a resistance element. Suitable electrical lead and an indicating recording . The resisting element is usually in the form of a coil of very fine platinum nickel or copper with no conductivity into an insulating frame of ceramic. The pressure tube may be evacuated with an inert gas to protect wire. A metal which has been strained will suffer a change in resistance. The metal is their fore usually annealed at temp. higher than at which it has to work or operate. Leads are taken out of the thermometer for the measurement of change in resistance in order to determine the value of temperature. The change in resistance is usually measured by a wheat stone bridge which may be used either in null condition or may be in defection mode. A metal used for fabrication of reusing element is required to satisfy following – Linearity of resistance → Temp relation slip for convenience in measurement . No change of phase or state with a reasonable temp change. Resistance to corrosion and absorption. High receptivity so that with may be fabricated in compact size. Ability of reproducing condition. ADVANTAGES: Simplicity and accuracy of operation . Flexibility and interchangeability. Positive temperature coefficient. High working signal level. ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) PROCEDURE: Connect the RTD at the i / p terminal if copper constantan is used. Cu must be connected to i/p and constantan to – ve terminal. Potentiometer should be turned to vim position container should contain sufficient water . Heater is suritched ou output of RTD is connect ed to input of DPM. RTD is dipped in water at room temp. and potentiometer is adjusted to get O DPM reading . When water starts boiling , potentiometer marked max is adjusted to get 100 DPM Heater is turned off so that water starts cooling. For lowering temp. of water RTD and DPM reading are noted and graphs are plotted. RESULT: The equation of best fit line y = mx + c CONCLUSION: The relation slip between input and output of RTD is studied and it is seem that RTD exhibits good linearity and good accuracy in comparison with the thermocouple. PRECAUTIONS: RTD should be handled very carefully. All connections should be made properly. The readings should be taken properly. ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) Experiment No.2 OBJECT- Study of velocity of fluid flow by Venturimeter. APPARATUS REQUIRED- Close circuit apparatus consisting of venturimeter pipeline with manometer, stopwatch. THEORY- A venturimeter is a device used for measuring the discharge of fluid Flow through pipe , it works on the principle that by reducing the cross sectional area of flow passage. A pressure differential is generated between the two cross sectional & by measuring this pressure difference the flow rate of fluid can be measured it consist of three parts namely converging pipe, throat and divergent cone. The theoretical discharge is – = constant = cross sectional area of section-1 =cross sectional area of through throat H= differential pressure head between section 1 & 2 For a differential U-tube manometer ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) Venturimeter Where, x= reading of manometer (difference in reading between 1 & 2 ) = sp. Gravity of liquid in U-tube = sp. Gravity of liquid flowing th. Pipe Actual discharge th. The pipe can be calculated by volumetric analysis- Where, Venturimeter ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) = &, = Therefore, PRECAUTIONS: Level of mercury in two limbs should be observed carefully & only in steady state. The instrument or apparatus should be leveled. ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) Experiment No.3 OBJECT- Study of velocity of fluid flow by Orifice meter APPARATUS REQUIRED- Close circuit apparatus consisting of Orifice meter pipeline with manometer, stopwatch. THEORY- A Orifice meter is a device used for measuring the discharge of fluid Flow through pipe, it works on the principle that by reducing the cross sectional area of flow passage. A pressure differential is generated between the two cross sectional & by measuring this pressure difference the flow rate of fluid can be measured it consist of three parts namely converging pipe, throat and divergent cone. The theoretical discharge is – = cross sectional area of section-1 =cross sectional area of through throat H= differential pressure head between section 1 & 2 ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) For a differential U-tube manometer Where, x= reading of manometer (difference in reading between 1 & 2 ) = sp. Gravity of liquid in U-tube = sp. Gravity of liquid flowing th. Pipe Actual discharge th. the pipe can be calculated by volumetric analysis- Where, ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) = &, = Therefore, PRECAUTIONS: Level of mercury in two limbs should be observed carefully & only in steady state. The instrument or apparatus should be leveled. ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) Experiment No.4 OBJECT: Study of velocity of fluid flow by Pitot tube. APPARATUS REQUIRED: Close circuit apparatus consisting of Pitot tube, pipeline with manometer, stopwatch. THEORY: It is a device used for measuring the velocity of any point in a pipe or channel. It is based on the principle that if the velocity of flow at a point becomes zero. The pressure there is increased due to pressure energy. In its simplest form the pitot tube consist of a glass tube, bend at right angles. The lower end which is bend through 90º is dejected in the upstream direction. The liquid rises up in the tube due to the conversion of kinetic energy into pressure energy. The velocity is determined by measuring the rise of liquid in the tube. Theoretical velocity is given by- Where, = co-efficient of pitot tube ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) Since velocity at any point, Velocity of flow in a pipe by pitot tube for finding the velocity at the point in a pipe in a pitot tube. The following arrangement is adopted: Pitot tube along with vertical piezometer tube. Pitot tube connected piezometer tube. Pitot tube & vertical piezometer tube connected with a differential U-tube manometer. Pitot tube which consists of two circular concentric tubes, one inside the other with some angular space in between the outlets of these two tubes tubes one connected to the differential manometer tube. When the difference of pressure head (h) is measured by knowing the difference level of manometer liquid (x) ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) Experiment No.5 OBJECT: To study construction and working of Bourdon Tube pressure gauge APPARATUS REQUIRED: Bourdon tube pressure gauge THEORY: A Bourdon tube Pressure gauge consists of a metallic tube, levers gears hairsprings and pointer and scale. The pressure responsive element of a Bourdon tube pressure gauge consists essentially of a metal tube called Bourdon Tube, oval in cross section and bent to form a circular segment of approx 200-300 degrees. The tube is fixed and opened at one end and it is through this end that the pressure is to be measured is applied .The other end is closed but free to allow displacement under deforming action of the pressure difference across the tube walls. When a pressure is applied to the inside of the tube ,its cross section tends to become circular. This makes the tube straighter itself out with a consequent increase in its radius of curvature .i.e. free end moves away from the centre .in case of vacuum the oval tube would collapse and curve. ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) The free end of the tube is connected to a spring loaded linkage which amplifies the displacement and transmits it to angular rotation of a pointer over a calibrated scale to give mechanical indication of pressure. The mechanism is so designed that it can be adjusted for optimum linearity and minimum hysteresis and to compensate for wears. Hair spring is used to faster the spindle to the frame of instrument to provide necessary tension for proper meshing of the gear teeth and thereby freeing system from backlash. Motion of free end, called ‘Tip Travel’ is a function of tube length, wall thickness, cross-section, geometry and modulus of tube material. The deflection of elemental tip, _a, is given as ∆a = 0.05 (aP/E) x (r/t)0.2 x (X/Y)0.33 x (X/t) 3 ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) Experiment No.6 OBJECT: Study of sensitivity of thermocouple. APPARATUS REQUIRED: Thermocouple, heater thermometer, wires, DPM hit. THEORY: The thermocouple is one of the most commonly used the method for measuring process temperature. The operation of thermocouple is based on see back effect discovered that when heat is applied to hot junction of two different materials, an emf. Is generated which can be measured at the cold junction. The two different junction materials form an electric circuits and current flow is the result of enf. The current will continue to flow as long as > T2. Metal B is described negative w. r. t. metal A if current flow into it at cold junction. Emf. Produced is a function of diff of temp between hot and cold junction is given as E = a Δ Q. Δ Q = Temperature difference between hot and cold junction. a = Constant. Since the thermocouple emf Depend upon difference of temp between cold and hot junction the temp of the later should remain absolutely constant in order that calibration holds good and there are no error on account of change of ambient temperature. The reverence junction is usually kept at O0 C . The reference junction is usually kept O0 C . Thermocouples are used for measurement of temp unto 1400 0 C. The confirmation holds good and there are no errors on change in ambient temperature of controlled reference junction. ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) Laws of Thermocouple – Law of homogeneous circuit : If heat is supplied to single homogeneous metal current will not flow Law of Intermediate Temperature The out gyrated in a Thermocouple with Junction at Temperature Δ is equal to sum of emus generated by Similar thermocouples one acting between temp. Δ and other Δ is equal to sum of emfs generated by similar Thermocouples one acting between temp. . Δ and other Δ where lies between. Law of intermediate metal – The introduction of third metal into the thermocouple ckt will have no effect on the emf generated as long as the junction of third metal with the thermocouple metals are at same temperature. See back Effect – The phenomenon by virtue of which a thermoelectric current is generated in a ckt. Comprising of two different metals when temp difference metals when temp. Difference is maintained across two junction is called see back effect. Peltier Effect – The phenomenon of absorption out evolution of heat at the junction of thermocouple when current passes thorough it is called politer effect. PRECAUTIONS: We should make the commission properly There should be minimum possible time lag between moving thermocouple from ice to hot water. ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) Experiment No.7 OBJECT: Study of ‘Liquid in glass tube’ (Thermometer.) apparatus. APPARATUS REQUIRED: Thermometer. THEORY: The liquid in glass thermometer is one of the most common types of temperature measuring devices. The unit consists of a glass envelope, a responsive liquid and an indicating scale. The envelope comprises a thick walled glass tube with a capillary bore, and a spherical or cylindrical bulb filled with liquid. The two parts are fused together and the top end of capillary tube is sealed. The size of capillary depends upon the size of sensing bulbs, responsive liquid and the desired temperature range of the instrument. Changes in the temperature will cause the fluid to expand and rise up the stem. Since the area of the stem is much less than the bulbs, the relatively small changes of fluid volume will result in significant fluid rise in the stem. The length of the movement of the free surface of the liquid column serves by a prior calibration, to indicate the temperature of the bulb. The laboratory work thermometer has a scale engraved directly on the glass stem, while the industry types have separate scale located adjacent to the stem. Outside offer the top of the capillary tube is also bulbs shaped to provide safety features in case of temperature range of the instrument is inadvertently exceeded. The thermometer bulb is usually filled with mercury. It has the advantage of a broad temperature span between its freezing and boiling points, nearly a linear Co-efficient of expansion relative ease of obtaining it in a very pure and its non wetting of glass characteristics, when measuring temp. Above the boiling point of mercury (390° C at atmospheric pressure) mercury evaporate and condensate the top of the stem. ST.ALOYSIUS INSTITUTE OF TECHNOLOGY, JABALPUR, DEPT.OF MECHANICAL ENGINEERING MECHANICAL MEASURMENT & CONTROL (ME-503) This is prevented by filling the space above necessary with nitrogen or carbon- dioxide under high pressure this raise the B. P. and allows temp. Up to 610°C to be measured. However, in many industrial applications the escape of mercury through breakage causes considerable damage to the products. This way necessitate the use of other liquids such as alcohol, pentane etc. which do not cause contamination .These liquids are also used for temperature measurement below freezing point of mercury .These liquids have further advantage of superior readability to mercury when colored with inert dyes and of low cost. However they have low boiling point, a greater tendency to separate in the capillary and wetting glass characteristics. The choice in the type of the glass used is a matter of economics influenced by the range of the thermometer the MECHANICAL MEASUREMENT LABORATORY higher the range, the higher the cost. For temperature up to 450°, normal glass is used .At high temperature up to about 520°CBorosilicate glass is used. Above this temperature, quartz thermometer has been used but they are not common.