25-2013, ACITIVITY HAZARD RISK ASSESSMENT

advertisement

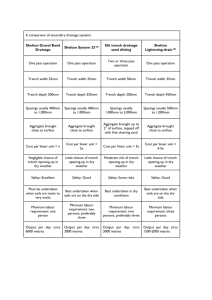

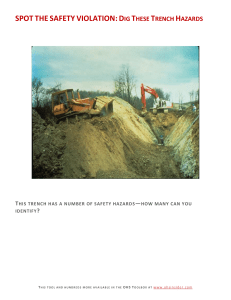

24 June 2013 From: Senior Safety Manager To: General Manager Subj: ACTIVITY HAZARD RISK ASSESSMENT #25-2013, FOR PNH PROJECT TO CONSTRUCT RESTROOM FACILITIES FOR MSC SSU IN BLDG. 6-4, EXCAVATION WORKS, AND IS AN ADDENDUM TO AHA #29 FROM 2012 FOR THE CONSTRUCTION OF THESE SPACES Ref: (a) USACE EM 385-1-1 (b) Ministry of Manpower Regulations Regarding General Safety and Health 1. Per reference (a), this risk assessment was completed to identify hazards that pose risk to workers, evaluate those hazards for severity and likelihood of occurrence, and recommend corrective actions that will eliminate or minimize hazards associated with the extent of excavation that is required for the completion of this project. On the original plan this level of excavation was not anticipated, however, after getting into the scope of the required work it was determined that a trench is required to run approximately 50 meter along the south end of Building 6-4 to install the drain lines required to support this new restroom facility. This AHA will be reviewed periodically and updated as needed to reflect changes in working conditions, processes or addition of new materials or equipment. Please address any questions or concerns to me at 8205 8249 or lee_wilson@pnhgrp.com. Respectfully, T. L. Wilson Risk Assessment Form #25-2013, Activity-Based Risk Assessment for Excavation Work at Bldg. 6-4, MSC SSU RESTROOMS Inventory of Work Activities Company: PNH Resources LTD PTE No. 1 Process Description Site Preparation 2 Trench Construction Work Activities Prepare the site for excavation work. The proposed trench will run between the south side of Bldg. 6-4 and the Australian Work Shop. Back Hoe and Manual Labor to be used to dig the trench 3 Install piping in trench Laying Pipe between the proposed restroom and 4 Fill in the trench Fill the trench with dirt obtained from digging the trench. 5 Heat Stress This work is being conducted outdoors and will present heat exposure challenges to workers. ACTIVITY RISK ASSESSMENT – MATRIX EMPLOYED TO QUANTIFY RISK Risk Criteria Severity (1-5, Lowest – Highest) Likelihood ( 1-5, Lowest - Highest) 24 June 2013 1-Negligible Injuries: slight injury or health effect, 2-Minor Injuries: Injury or ill health requiring first aid treatment only 3-Moderate Injury: Injury requiring medical treatment or ill health leading to disability 4-Major Injury Disability: serious injury or life threatening occupational disease 5-Castrophic: serious injury resulting in fatality or irreversible health damage with death 1-Rare: very unlikely to happen, 2-Remote: not likely to happen most of the time, 3-Occasional: likely to happen sometime, 4-Major Injury Disability: likely to happen several times regularly, 5-Almost Certain: Likely to happen Risk Level (Severity x Likelihood) Trivial Risk : Tolerable Risk : Moderate Risk : Substantial Risk : Intolerable Risk : 1 to 2 (L) 3 to 9 (L) 10 to 19 (M) 20 to 24 (H) 25 (H) - First aid treatment injury, minor cuts or bruises, clean-up effort for environmental impact - First aid treatment Injury, minor cuts or bruises, clean-up effort for environmental impact - Temporary disability, lost time injury, outpatient treatment, minor or short term environmental impact - Serious Injury, permanent disability, major disruption and damage to equipment or structure, significant environmental - Fatality or fatalities, serious injury, permanent disability, major structural or equipment damage, detriment environmental The table above provides numerical methodology to better prioritize hazards. These values are the criteria for the Activity-Based Risk Assessments beginning on the following page. No catastrophic risk of any certainty was identified. Risk Assessment Form Activity-Based Risk Assessment Form Company: PNH RESOURCES PTE LTD Process/Location: Tree Trimming/Pruning/Removal at the Sembawang Complex, Sembawang, Sg. Approved by: Joseph Lim (Name, designation) General Manager (Date) 24 June 2013 1. Hazard Identification Conducted by: (Names, designations) (Date) Ministry of Manpower Regulations Ref: EM385-1-1, Chp. 31 Last Review 24 June 2013 Date: 1b 1c 1d 2a 2b No Work Activity Hazard Possible Accident/ Ill Health & Persons at Risk Existing Risk Control (if any) Severity Site Preparation – the area where the trench is to be constructed is not a significant traffic area but there is access to the general public and they must be protected from falling into the trench when it is open Cave in trapping workers – The anticipated depth of the trench to be no greater than 1.3 meters and at this depth, a protective system is not required, Workers down in the trench which could also be affected by weather conditions i.e. rain could make trench sides more unstable. Falling into the trench – Workers on this project in addition to others who 2 Next Review Date: 2. Risk Evaluation 1a 1 Lee Wilson Senior Safety Manager 24 June 2013 The project manager shall observe the condition of the trench sides. 01 December 2013 3. Risk Control 2c 2d 3a 3b Liklihood Risk Level Additional Risk Control Action Officer Designation 2 2 4 Shoring materials are available on site to be deployed as needed. Senior Safety Manager 3 2 6 Signage should be posted to alert all in the vicinity of the worksite of the potential hazards. Senior Safety Manager The soil was noted to be of a sandy clay type of material. wander into the worksite. No 2 3 Work Activity Hazard Digging of the Trench – A subcontractor will be employed to mechanically dig the trench with the assistance of mechanical diggers. Lacerations, Bruising and Crushing type of injuries from accidental or incidental contact with the back hoe machine. Workers performing manual labor adjacent to the backhoe when it is being used. Musculoskeletal Installing pipe in the trench Possible Accident/ Ill Health & Persons at Risk Existing Risk Control (if any) Severity Likely- Risk hood Level Project supervisor shall ensure that workers maintain a safe distance (a minimum of 10 meter) away from the backhoe when it is in operation. 3 2 Personnel engaging in manual digging operations may be subject to strains and sprains to ligaments and muscle structures. Workers have received training with regards to preventing these types of injuries and also the value to teamwork in the completion of this type of work. 2 2 4 Sight Hazard from flying debris Workers involved with the excavation of the trench Workers have been issue sight protection and have received training on the need to wear this equipment on the job at all times. 2 2 4 PNH workers receive Sight Conservation training several times a year and more often as the work may dictate. Senior Safety Manager Musculoskeletal Workers actively involved with the pipe installation Training, utilizing teamwork as needed. 2 2 4 The risk level is considered to be low as the workers performing this labor are young, in good health and have been screened for exiting musculoskeletal type Senior Safety Manager 6 Additional Risk Control Report any and all near misses or any situations where a lessons learned situation may exist. Workers need to be wearing all of their issued PPE on the job including: Safety Shoes Hard Hats Eye Protection & Hearing Protection when working around the backhoe. The risk level is considered to be low as the workers performing this labor are young, in good health and have been screened for exiting musculoskeletal type of injuries. Action Officer Designation Senior Safety Manager Senior Safety Manager of injuries. No 4 5 Work Activity Hazard Possible Accident/ Ill Health & Persons at Risk Existing Risk Control (if any) Fill in the trench Fall hazard – the dirt on the sides of the trench is loose and could facilitate workers stumbling and falling into the trench and being injured. Workers involved with filling in the trench after the pipe has been laid Lacerations due to shovel work Heat Cramps Heat Rash Heat Syncope Heat Exhaustion* Heat Stroke** Heat Stress *If not treated properly can progress to heat stroke. **Life Threatening and is a real medical emergency. Definitive medical assistance must be summoned. Severity Likely- Risk hood Level Additional Risk Control Action Officer Designation Attention to the work environment and ensuring that hasty work does not facilitate increased risk. 2 3 6 Report all injuries sustained to the project manager and Safety Department. Senior Safety Manager Workers working with shovels and other workers who may be in the area. Attention to the work environment and knowing the proximity to other workers. 2 3 6 Ensure that it is understood that too many workers in a small area can facilitate accidents and injuries. Senior Safety Manager Personnel performing work outdoor in Singapore Tool Box Talk Training concerning heat stress, clean drinking water at all job sites, sufficient rest periods for workers in accordance with NAVMED P-5010 and Ministry of Manpower Recommendations 3 2 6 Continue emphasis on heat injuries whenever safety stand downs, events, tool box talks etc.. are planned. Ensure that drinking water is always available for crews working in heat stress conditions. Ensure that sub contractors receive training on the Heat Stress Program observed at the Sembawang Compound including the use of colored flags. A flag system is employed at the Fleet Gym which is adjacent to this project. Supervisors shall also ensure that workers have ample opportunity to drink water as needed and take breaks during periods of extreme heat especially if the heat index hits 34C or above. Senior Safety Manager Heat Stress (Color) Green Yellow Red Black Calculations: Condition I II III IV Heat Stress WBGT Temperature Activity Level 27.78-29.39 C (82-84.9F) Discretion is required when planning heavy exercise for acclimatized personnel. 29.44-31.06 C (85-87.9F) Strenuous exercise and activity for new and un-acclimatized personnel during the first 30 days of heat exposure. 31.11-32.17 C (88-89.9F) Strenuous exercise should be curtailed for personnel with less than 12 weeks of training in hot weather. Above 32.22 C or (Above Physical training and exercise should be curtailed for all personnel (operational commitments excluded). 90F) Heat stroke likelihood is high under conditions of high exertion. WBGT = WB X 0.7 + DB X 0.1 + GT X 0.2 Meter calibration should be manually verified every 3 months. Manual calculation must be 0.2 + the meter WBGT readout