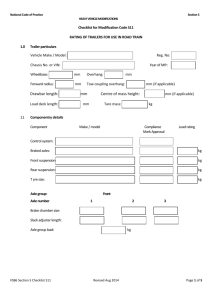

DOCX: 40 KB

advertisement

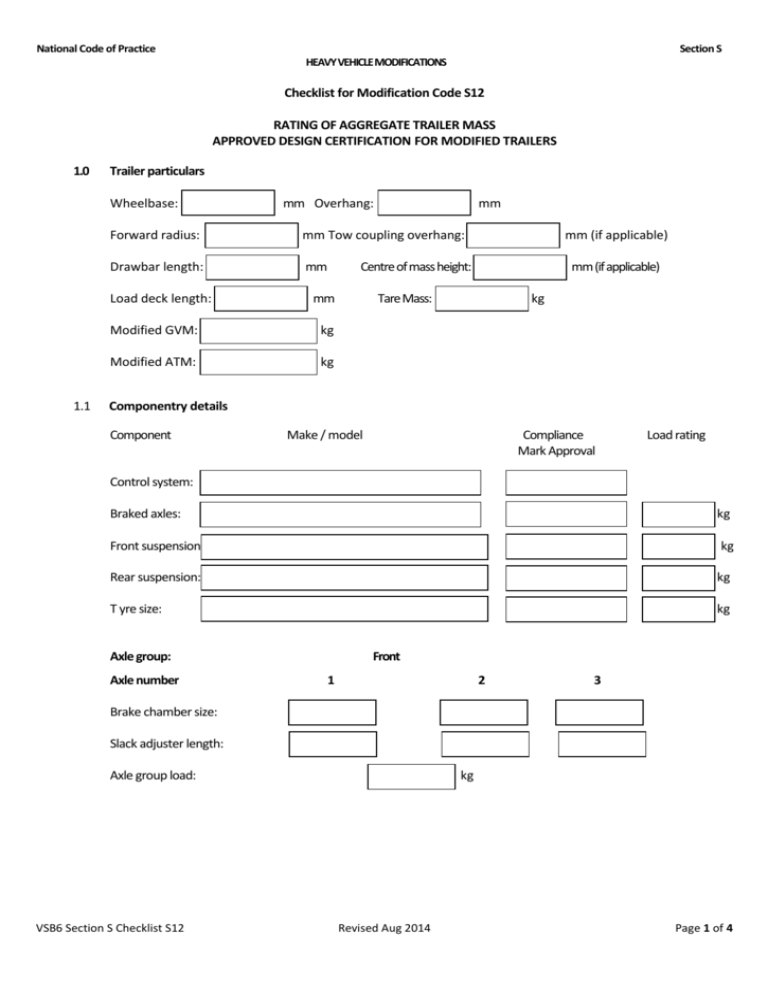

National Code of Practice Section S HEAVY VEHICLE MODIFICATIONS Checklist for Modification Code S12 RATING OF AGGREGATE TRAILER MASS APPROVED DESIGN CERTIFICATION FOR MODIFIED TRAILERS 1.0 Trailer particulars Wheelbase: mm Forward radius: mm Tow coupling overhang: Drawbar length: mm Load deck length: 1.1 mm Overhang: mm (if applicable) Centre of mass height: mm Modified GVM: kg Modified ATM: kg mm (if applicable) Tare Mass: kg Componentry details Component Make / model Compliance Mark Approval Load rating Control system: Braked axles: kg Front suspension: kg Rear suspension: kg T yre size: kg Axle group: Axle number Front 1 2 3 Brake chamber size: Slack adjuster length: Axle group load: VSB6 Section S Checklist S12 kg Revised Aug 2014 Page 1 of 4 National Code of Practice Section S HEAVY VEHICLE MODIFICATIONS Axle group: Rear Axle number 1 2 3 4 Brake chamber size: Slack adjuster length: Axle group load: kg Chassis construction: Front Tow coupling/Fifth wheel: Make/model: D-rating: kg 1.2 Calculated braking performance Calculated ERC deceleration performance relative to ADR 38/.. upper and lower boundaries at different control signal strengths. Control signal 'E' 0.2 0.4 0.6 0.8 1.0 Control signal ,kPa 130 260 390 520 650 Upper limit .140 .305 .470 .635 .800 Lower limit .029 .158 .286 .394 .482 Calculated ERC Parking grade percent at modified ATM: Emergency skid limit: % Certified suspension skid limit: Dog trailer: Front friction utilization: at: ERC Rear friction utilization: Axle fade rating required: VSB6 Section S Checklist S12 tonnes Revised Aug 2014 Page 2 of 4 National Code of Practice Section S HEAVY VEHICLE MODIFICATIONS (Y=Yes, N= No or N/A=Not Applicable) 2.0 General 2.1 Retention of records 2.1.1 2.2 Have all calculations required to establish the modified ATM been retained for future audit? Chassis 2.2.1 Has the chassis construction been assessed (by calculations) to be adequate for the modified axle group loads and ATM? 2.2.2 Are the trailer dimensions within the permitted maximum limits? 2.3 Brake system 2.3.1 Are the requirements of ADR 38/.. met for ERC, emergency skid limits, friction utilisation and axle fade rating ? 2.3.2 Does the parking brake ability exceed 18% gradient at the modified ATM? 2.4 Tow Coupling 2.4.1 Do the tow coupling, tow coupling mounting components and drawbar (if applicable) meet the requirements of ADR 62/..? 3.0 Trailer inspection records (Not required if certificate without plate is issued to an S7 Officer who will conduct the trailer inspection). 3.1 Chassis 3.1.1 3.2 Does the chassis conform to the detail construction, section properties, cross member location and dimensions of the S12 Officer's report? Brake system 3.2.1 Is the trailer's entire braking system, including brake chamber sizes and slack adjuster length setting, identical to the braking system described in Section 1of this report? 3.2.2 Have the brake system piping lengths been established to not exceed the maximum lengths specified in the control system manufacturer's certified data sheet? 3.3 Tyres and Rims 3.3.1 Does the tyre placard (if fitted) record the correct tyre and rim sizes, axle configurations, axle loads and inflation pressures for the modified trailer? 3.3.2 Are tyres and rims fitted in accordance with the tyre placard? 3.4 Tow Coupling VSB6 Section S Checklist S12 Revised Aug 2014 Page 3 of 4 National Code of Practice Section S HEAVY VEHICLE MODIFICATIONS 3.4.1 3.5 Does the installation of the tow coupling, tow coupling mounting and drawbar (if applicable) meet the requirements of ADR 62/..? Workmanship 3.5.1 Is the quality of workmanship to a satisfactory standard? NOTE: If the answer to any relevant question is "NO", the modification is not acceptable. Trailer identity and information source Trailer Make / Model: Chassis No. or VIN: Year of Mfr: Trailer Modified By: Trailer examined or details supplied by: Company (if applicable): Certification Trailer inspected Yes or No: Modification Plate No. issued: Yes or No: (Applicable only if trailer inspected) Certificate number: Certificate approved by: Company (if applicable): Signed when printed: Certifying Officer No: Date: If Certificate issued to S7 Officer: Certificate and checklist issued to: Company: Certifying Officer No: Note: A copy of this checklist must be supplied with the certificate to the S7 Certifying Officer. VSB6 Section S Checklist S12 Revised Aug 2014 Page 4 of 4