transcript - WordPress.com

advertisement

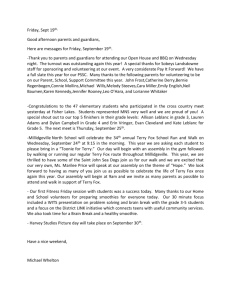

Interview with Burr Sebring, Conducted by Raina Fox Note: This is a transcript of an interview with Burr Sebring conducted in his studio in Barrington, Rhode Island, on Saturday, March 9, 2013. 1 Note: Interviewer began to record before the interview’s official commencement, in order to capture a story the interviewee was telling. His reference to Minneapolis is a response to the interviewer’s hometown. Burr Sebring: [Been to] Minneapolis a couple of times. Raina Fox: Really. Sebring: We would take surveys around the country. Fox: Really. Sebring: Flatware surveys. Been there a couple times. Many, many, many, many places. We’d start up the East Coast, realize there were different . . . different sections, different styles of flatware. I know the Northeast is sort of plain, and the South was a little more ornate and the Midwest is totally different, with hearts and flowers usually. And the West coast, they were always themselves. They had a different view of everything. But it was interesting [1.00] that different styles around the country. And we had to come back and sort of melt that all together, and, I’m not so sure that we did a good job, you know, trying to meld everything together. Fox: How did you try to meld it together? What kinds of designs would you create that melded those . . . Sebring: Oh, I did a classic pattern that . . . several. Fox: So, I should have started with this, but we also want to mark the tape so that officially we know who we are, because someone in the future may listen to this and not know. So, to begin, my name is Raina Fox and I am a student at Brown University and today is Saturday, March [ninth], 2013, I think it’s about 1:10 in the afternoon. And would you like to introduce yourself? [Pause, louder] Can you introduce yourself? Sebring: Oh, I’m Burr Sebring, I live in Barrington Rhode Island. I’ve been in Rhode Island since 1958, first went to Gorham when out of school in Rochester, was there as a designer, craftsman. Later became design director in ’71, ‘til ‘81. And since that time I’ve been on my own - up until now, and still doing things. Fox: So can you actually walk me through your experience at Gorham and how you ended up there? Sebring: I won a competition from the school of American craftsmen, a national competition and two guys were there, one from Gorham and one at the show in New York, a presentation, a gentleman from Reed & Barton. And a gentleman from Gorham. He said, “when you get out of school, look us up.” [laughter] so I first went to Reed & Barton and on the way back from 2 Taunton I stopped in [Brownuts? inaudable] to see Gorham and was hired [3.19] on the spot in 1958. I got there out of school in I think June and I was working at Gorham in August. Designer, craftsman. I was doing mostly flatware, some hollow ware. I was, became Design Director I believe in 1972. And was Design Director from then on until ’81, until I left Gorham. Fox: Wow, so you had been in college when they found you? What did you study when you were in school? Sebring: I studied silversmithing. School for American craftsmen had pottery, they had ceramics, weaving, metal smithing, silversmithing, and woodworking at the school in Rochester. That’s really how I got my start. Like, after the army, I decided I wanted to go back to school, and my high school experience revolved around my shop teacher was a silversmith guy, and it always appealed to me and he did some silversmithing in high school that I watched him do and I was fascinated and after the army decided that’s what I wanted to do and Rochester was close by so I went back to school. Fox: Wow, what did you do in the army? Sebring: I was a Quartermaster. [5.15] I played a lot of sports. Fox: What kinds of sports? Sebring: Karl Braun, former Knickerbocker, New York Knick guy was in our outfit and he organized the basketball team and after basketball he had tried out with the Yankees. He didn’t get very far but he was a good ball player. So we had a baseball team in the spring, and we had a football team in the fall and for two years I played ball. Fox: Wow, where? Sebring: Northfield, North Carolina, Fort Prague. Fox: That’s amazing. And what made you decide to become a silversmith? I know you said you took a class in high school . . . Sebring: Well, just I met a lot of guys in the service who had been to school, and I just decided I was going to go back to school. And the experience in high school with that shop guy, it was, seemed like a natural to be in Rochester. Fox: What did you like about silversmithing when you were in high school? Sebring: Oh I don’t know I just, the way he raised things from flat stock. I didn’t realize anything like that could be possible, and it just fascinated me. [6.51] Fox: What kinds of things did you make then? 3 Sebring: I didn’t make anything really in high school, I just watched him because I just didn’t think I was - and I know he thought I wasn’t- that qualified, so he was making small jewelry things and also some small hollowware pieces in silver. Fox: So once you came to Gorham, you said that you were hired right out of school but were you hired to do a specific kind of design work? Sebring: Not really, I think the first six months I remember doing working drawings. Somebody else’s design and I did the working drawings for them. but I think that was pretty standard operating procedure for most all young guys coming in. [7.49] Fox: Why? Sebring: I had a great experience in Gorham. I was able to, with my flatware background, and we were starting in on some stainless steel, I was sent overseas to the Orient many, many, times, and that experience has stayed with me the rest of my career. And I still work with a Japanese guy and a South Korea guy making flatware. Fox: Wow. What was it that you did there? Sebring: Take the designs over, make sure that the dyes were made correctly and the final product was satisfactory. Fox: So you were learning from their processes? Or were they creating objects for . . . Sebring: No we’d take the design over and they would manufacture the flatware. We first went to Japan, we went to Taiwan, went to South Korea, Indonesia, and finally wound up in China. [9.13] Fox: Wow. Sebring: It’s very very much a hand operation and the manufacturer followed cheaper hands. It got too expensive in Japan, so the flatware moved to Taiwan as I remember and just kept rolling until it finally would up in China. That’s where most of the stainless steel is done now. But that experience in Gorham lead me to what I’m doing now. Fox: How? How did it lead you there? How did that experience lead you to where you are now? Sebring: Well, it’s the contacts from oversees. They just they knew I could design and they had manufacture facilities and so we just got together. Fox: So what is it that you do? Sebring: Now? Fox: Yeah, now. 4 Sebring: Now, well, I still make some flatware, [10.20] samples, designs and stuff like that. [Here Sebring stood up and walked to his workbench. The following conversation took place at the workbench, referring to specific objects, photo Figure 2.] Fox: Sorry? Oh wow, this is beautiful! Wow, it almost looks like it’s been hand, I don’t know the terminology but these textures. . . Sebring: Hammered. Fox: Hammered, yeah. Sebring: This thing, this is a new one. And that’s how, this is what I do. I made that from scratch and this is made out of a piece of brass that’s a model for their dyes. And then just starting to work on that. Fox: Wow! This is so cool! Sebring: [Laughs] Fox: I’ve never seen this process before, that’s amazing. So it looks like you make the handle separately and then you add the . . . Sebring: Yeah. These two handles will do all the pieces. This will do all the flat pieces. And this will do all the hollow pieces, hollowware. Fox: So when you create something like this, it looks like this is a separate piece from this. Is that right? Sebring: This will be the knife. . . I, I, I don’t do the blade ‘cause it’s not necessary, they’ll attach a blade to this. Fox: Got it, okay. So do the techniques you use here reflect . . . are they similar to what they do there? Sebring: They will take this and put it in a bowl, and from a mold, they’ll put it and they’ll make a dye, steel dye, a top dye and a bottom dye. Squash it together, and you’ll come out with a piece like that. Fox: Wow. And so, when they add the blade that also goes into the mold? Sebring: Yes. 5 Fox: Okay. Wow, that’s so interesting. Sebring: This is gold, I’m making this for my granddaughter. It’s a gold wire weaving made out of these rings here. Fox: Wow, that’s beautiful! It’s so delicate. How do you do that? Sebring: These get saudered. [12. 31] they’ll get opened, they’ll get saudered together and squash them, once they’re squashed you stick it in there, zip it up and then turn it, do another one, turn it, and do another one. Fox: Wow. Did you learn how to do this technique? Sebring: No, it was Cleveland Art Institute, John Paul Miller is rather famous for this kind of chain and it always fascinated me and I just sort of copied it. Fox: Were you in Cleveland, how did you . . . [louder] You were in Cleveland? How did you meet him? Sebring: I had a friend in Cleveland who went to the art institute and he showed me how to do it. He learned from John Paul. Some time Google John Paul Miller. Fox: Jean Millar? Sebring: John M-I-L-L-E-R. Fox: Miller. Sebring: You will be surprised. Fox: What does he make? Sebring: Gold Jewelry. Fantastic. Fox: Did you also make jewelry? Have you always made flatware? [louder] Did you make jewelry too or always flatware? Sebring: No, just for fun. You know, for my offspring I’ve done some things. I’ve done some bracelets here. This one, I made some cuff bracelets, but I’d rather do flatware. Fox: They’re beautiful. You said you have a granddaughter? How old is she? Sebring: She’s fifteen. It will go around twice. Fox: That’s beautiful. Do your grandchildren or your children like to learn about all of these processes? 6 Sebring: Cole is a grandson, he’s 10. He’s a sports guy. Lacrosse, basketball, football. Big guy. Fox: So he learned those from you, it sounds like you also did sports. Sebring: He’s a good athlete too. So it’s sort of a natural for him. [Sitting down again] Fox: So you said you played sports while you were in the army [15.00]. Did you also, were there sports teams at Gorham, or were there leagues? Sebring: There was a softball team, yes. Fox: Did you play? Sebring: Two or three years, maybe. We had a lot of fun in the basement of that casino. There were five or six duck pin lanes in the basement. And we would play over there for once a week. Right after work, maybe until eight o’clock at night. Fox: Wow. Sebring: It’s just a shame they burnt that up, some guys got in one night when there was no one, the main building was empty, had been sold. And some guys got in, tried to keep warm, they built a fire inside, on the floor and away it went. But that was a grand building. The second floor windows that was the executive dining room. With stained glass windows, you cans see up at the top. I always remember going in the front at noontime. The ladies would be on the right and the guys would be on the left. Absolutely separated. And they were that way until I left there in ‘81. Fox: Wow. [16.30] Why were they separated? Sebring: That was the way it was. I mean, I think it seems to you now rather strange, but that’s the way it was back then. Fox: Were there a lot of ladies working there too? Sebring: About half. Well, maybe not quite half. Maybe 40% of workforce. When I got there, there was a thousand [17] employees at Gorham, and it dwindled and dwindled down and down. It’s just a shame that building’s gone. I would wish the Providence historical society had taken it over, maybe they could’ve saved it. But . . It was just a derelict and . . . gone. . . gone. And the building’s gone too. It was a three story mill building, typical mill. Downstairs had the executive offices. They were all mahogany panel, with a fireplace in each office. And the secretary had an adjoining room, she never was in the big office with the guys, they were always separate. Fox: How was the . . . oh, sorry. Sebring: Go ahead. 7 Fox: How was the rest of the factory set up? Sebring: Well, we had a rolling mill. We rolled our own silver from silvering nuts. We had three large vaults. One of them held silvering nuts and they would be, melted down and rolled in our rolling mill that just fed the factory it didn’t do material for anyone else it was just to furnish the factory with the material. And we had a stamping room, engraving room, chasing room, buffing room, a dye cutters room. Pretty complete. They had a printing shop in the basement of the building. [19.06] Fox: What was the interaction between the departments? Did people get along well? Did people know . . . Sebring: Yes, very well. Until the union arrived. And then it sort of changed. And then after the union, maybe ten or [19.31] twelve, fifteen years there was a strike. And then that really separated the departments, you know from the merchandise department and design, salespeople, were really quite separated from the factory at that point. It was a shame. An absolute shame. But it happened. In fact there were two strikes. When I first got there, there was a strike going on in ’58. I had to cross a picket line. It so happened I was making a piece for . . . a piece of silver, handmade piece, and they could, it was in the middle of summer, the windows were awful, and the pickets could hear my hammering. And [laughs] they made quite a fuss about that. Because they didn’t, you know, no one was supposed to be working. And they couldn’t figure out why someone in the merchandise department or in marketing would be hammering on silver [laughs] [20.51] and they didn’t know it was me, either, so I was in and out of the picket line okay, no problem. But it was a very divisive affair. Both strikes. The one lasted maybe six months. Six or eight months. We tried to keep some production going but it was very difficult trying to get salespeople retrained to be a buffer or a trying to get merchandise out the door. Very difficult. Not a good time. Fox: What did it feel like to work there then? You said it wasn’t a good time. What did it feel like to work there at that time? Sebring: Oh, as I say very divisive. They were, they were angry. Very angry. Had pickets and unfortunately they had some collaboration with the Providence police, they, that’s a union, and the guys stick together a little bit. There were incidents on the picket line and the police would tend to overlook and that was, oh, it was just a bad situation. [22.26] Fox: And how did you feel being there then? Sebring: The second one was there after I was there awhile but the first one I didn’t get the ramifications. I mean, I was young and I just went in and out, but the second one, I had been there maybe 15 years and knew all of the guys in the picket line. Good buddies. And it changed. And it was never the same. 8 Fox: How? How did it change? Sebring: Oh, personalities. They would, they did some things on the picket line that were not too good and then you know you don’t forget those things. [23.23] Fox: Do you have an example of one of those things or do you not want to talk about them? Sebring: An example of . . .? Fox: An example of one of the things that happened on the picket line? Sebring: Oh, I don’t know, because I just, I don’t know. Fox: That’s fine. Sebring: You don’t know who’s going to listen to this. Fox: That’s fine. You have just as much right to say no to answer questions. Actually, if you don’t mind I’m going to pause for just a second. [23.47] ---------------[Pause while interviewer changes batteries] ----------------Sebring: No feeling for the company. The company was doing them wrong and they took it out on everybody that was going in through the picket line. Fox: So, you said the first one was in 1958? Sebring: That was the first strike. Fox: When was the second one? Sebring: Maybe twelve, fifteen years later. That was the severe one. Where a lot of the marketing people worked up buffering, finishing. We got some flatware out, but not a lot. Not what we normally do. Fox: Did it affect business? Sebring: Yes it did. See, the only way, there was not a lot of sterling business, even back then. It was dwindling. And the only way really to gain, gain any, any advantage was to sort of dig it out of your competitor. There was no new business much. And if Reed & Barton or Towle or those guys were doing something good we tried to do it, match it, or do it a little bit better or something like that. But there was not any new business generally. Now new. 9 Fox: You were mentioning that Gorham was starting to produce things overseas at that point too. Do you think there was a connection at all? Sebring: Well the union didn’t like that, certainly. But the overseas ware was much, much superior. They were doing things that – with steel especially – that we weren’t doing. Plus, cheaper. I’m sure. It was a two-way-street I guess, with the union. Fox: What were some [26.14] of the ways that it benefited? You said it was a two way street? Sebring: Well, because it took, the work when it goes oversees that means the union doesn’t have so much work to do. . . . But and on the other hand, for Gorham it was good merchandizing and cheaper. Fox: And you said that the silver sterling that they were doing was different in Asia? Sebring: Well, the quality was superior. Fox: How? Sebring: Very, very good weight. And steel. Good finishing. And we were not doing that type of quality. Eventually we did. A lot of work came back to Gorham. But it took a long time to get the work back from, from overseas. [27.11] But they made, Gorham eventually made very good steel flatware. Fox: Do you remember the first time you went to Asia? Sebring: I think I do. I remember the sun never went out of the left hand window of the plane. We followed the sun over. And it was . . . it’s a long ride. But I remember getting off and in the airport absolutely. . . I’d been, I’d been to Europe several times and it was different in Japan. It’s a totally different world. Not so much now but back thirty years ago it was a different . . . first of all, the language. . . and they’re very proper. And very, they were good buddies after awhile. But it was a different atmosphere then, that first time I went over. I couldn’t believe it. Fox: It must have been a very interesting cultural experience then. Sebring: I think just to Japan I’ve made 25 trips maybe. I figure that one time I go for two weeks maybe, three weeks. But combined I’ve spent a year in Japan. Fox: Wow, that’s amazing. And still, you still work with some of the people you met. Sebring: Yes I do, I work with a guy from Yokohama, yeah. I Skype, Skype him a couple times a week. He’s right there in front of me. I can show him, you know, in front of the camera. Fox: That’s so neat. 10 Sebring: The technology is so changed. So much. I remember talking to him on the phone and there’d be a pause between, you know, when he’d stop talking and I’d start talking. Calling the operator for long distance oversees and it took three or four minutes to make the connection. [30.05] now with Skype I can, he comes on the iPad in maybe, less than ten seconds. Unbelievable. Fox: It really is. Sebring: Yes. And he’s there, talking to him. And it’s usually almost a 24 hour difference. So I’m talking to him when it’s dark here and the sunshine is coming through his window and it looks good to me. [laughs] Fox: That’s so neat. And I bet the technologies related to creating the flatware have also changed. Sebring: Not a lot. No, not a lot. It’s still stroke and dyes. Steel dyes and steel dyes are very, very expensive, very slow to make and they have to do a lot of handwork in steel. They do the negative of a piece of flatware, which is very difficult. No that technology’s still, still there. That hasn’t changed a lot. Fox: Do you feel like people have these skills still in general though? Sebring: No, not here, anymore. They’ve gone. But they do have skills over there. Very, very, few dye cutters and that skill is just gone. I think the jewelry people still have dye cutters but the flatware people like Reed & Barton they do the same thing. They go overseas, international. [31.57] Towle. They’ve all gone overseas to get their tooling and made. Fox: Why do you think those skills were lost here? Is it because the connection . . . [louder] sorry, why do you think those skills here were lost? Was it because . . . Sebring: Well, the product had gone overseas, they just, there was nothing, nothing to do here. You know. They didn’t, if they didn’t make flatware here they didn’t have to make dyes, so. The skills gone down. In fact very, very few people have. . . I have some names here for you if you come. . . [Sebring stands and leads Fox to desk, takes out handwritten list of names.] Fox: Great, thank you so much! [Sebring rips page out of notebook to give Fox] Sebring: This is, Werner lives up in Scituate, silversmith. Probably one of the top five in the United States. Good. And he’s got a lot of information. David Rogers is a buddy, lives here in Barrington. He was a modeler and designer. Dick Cragin lives in Cumberland, a designer. Fred 11 Roy took my spot after I left as Design Director, and his father was a VP for manufacturing, and he’s still alive and he would be a good guy to contact at work. Fox: This is wonderful, thank you so much. Sebring: Yes. [33.43] Fox: And I know that Elizabeth [Williams, Curator of Decorative Arts at RISD Museum] mentioned that there was sort of a long process before you leaving where there were sort of different people who came in as the head of Gorham. Was that right, where Textron came in? I was wondering if you could tell me a little bit about that shift? [Sebring hesitates]. You don’t have to, again. Okay, that’s fine. Sebring: Off the record I can talk. [34.09] Fox: Okay. [Off the record conversation about Textron’s involvement at Gorham, edited out at Sebring’s request.] Fox: Do you mind if I turn on the recorder again? I’d love to hear more about your time in that neighborhood, too. I know that you said you lived near Gorham, is that right? [34.20] Sebring: Oh, but not long, no. On Adelaide, yes. The Gorham address was 333 Adelaide and we lived maybe when I first got here in ’58 we lived on Adelaide maybe three blocks away, for maybe six months. It was a pretty tough spot, so we found a place on East Side on Planet. Do you know Planet? Fox: Yes, actually. It’s a beautiful area. Sebring: Yeah. It’s the first house to the South on, from Benefit. Burnside is over on the, Burnside apartment, big red one? We lived there for a long, had our children there. We were there ten years maybe before we came to Barrington. But it was, it was a great neighborhood. Fox: You mean the East Side was a great neighborhood? [Louder] The East Side? Sebring: Yes. A lot of Brown guys were friends. But they wouldn’t, you know, they’d come in and - as yourself - come in for two or three years and then go. Gone. We had a lot of Brown 12 associates. Good times there. But the kids would have had to grow up and gone to school in Fox Point and we decided to come to Barrington. We’ve been here since ’61. Long time. Fox: And would you commute every day? Sebring: Yeah. Fox: How long did that take? How did you commute? Sebring: Oh, not long. Maybe 20 minutes. I’d just stay out of the traffic. I went a little early and came back late so there was no problem. Fox: When did you have to go to miss traffic? What time would you arrive at work? Sebring: Oh, I went in maybe 7:15 I think it was I’d go in and most of the people, I think 20 minutes later. [37.00] You get so you’re pretty aware of what’s going on. Fox: When different people come in and when they leave. Yeah. So, where did other people live? Other people you worked with? Were they mostly in that neighborhood, or were they elsewhere? Sebring: No, hardly any folks lived in the neighborhood. Back in the days of ‘80’s, ‘90’s and teens I think that neighborhood was all Gorham that around that Adelaide was all Gorham folks. Fox: The 1890’s? Sebring: Yeah. It’s heyday really was the ‘80’s and ‘90’s. That’s when Gorham was really cooking. Great designer, Codman. He did all the things. Sterling patter, Chantilly buttercup, Strasbourg, he did all of those and they were the mainstay of the company for a long, long, long, long time. And he did the table. Good man. It’s always bothered me that I was I left and that at the end it didn’t seem to be a lot I could do about changing the ways, but I was there at the demise and all the, I felt badly about all the people before me. All the good designers. A waste. Gone. Fox: Where did they go when they left? Sebring: The designers? We had, well, so Woodward left when he was eighty. So they took it easy I think. People would stay and stay and stay at Gorham. I remember the president said well, how old is Russell? I said, “I think he’s eighty.” He said “Burr! What’s going to happen if he has an accident? And the people ask him, ‘where are you going?’ and he says ‘well, I’m going to work, to Gorham’?” he said, ‘I don’t want to hear that.’ So, we had to turn Russell out to pasture. Good designer. Good man. And we had several like that. I don’t know, designers improve with age, generally, I think. When you get a little, a little background in what you’re doing it helps. Fox: Do you think that your style has changed? 13 Sebring: I don’t think my style, and I don’t, I’m not sure. I don’t think a lot. But the way I attack things has changed. I do it a lot easier now than I did before. [Laughs] [40.31] Fox: You have practice. And are you inspired by different designs? What inspires the designs you make? Sebring: Well, John Paul Miller, he inspires me. But, no it’s the things around me. I just think about a lot of things and I try to make them, I see them, and then, and then I work problems out around that and sort of critique myself. Most of the things are pretty well designed before they even hit the paper. If I sit down and try to design on paper, it turns out to be a bunch of clichés. Fox: We can pause. [Sebring’s adult son, Peter, interrupted looking for his father. There is a break in the audio during a short conversation with him.] Peter: The carriage house is gone. Sebring: Yes, the carriage house is gone. The carriage house is not unlike the casino. Beautiful building. Just, absolutely beautiful. The old stalls were there for the horses, and some carriages were still there when I got there in 1958. Gone. [Peter leaves] Fox: What was the carriage house? Sebring: It was what we’d call the garage now. Kept cars there but before it was horses and carriages in the ‘80’s and ‘90’s. All gone. The building’s gone. The casino’s gone. And the factory’s gone. And it just, not much more than a hundred years. [42.27] The building I think was done in ’95. And it was gone in 1995. That’s a sad . . . I don’t know. But as I said in the ‘80’s and ‘90’s that’s when the, that’s when things were pretty . . . Just a good, good, good product. Fox: What do you think made - this is just out of curiosity but – what made Gorham products different? It seems like there was a very unique Gorham quality. Sebring: I think the design, I think Codman. Codman did it. And Holbrook, too, was an old guy. [Pointing at list of contacts]. Well, these other guys will help you. Werner, Werner was a factory guy. He worked in silversmithing. Let me show you something he did. [Takes out a copy of Perspective, Figure 3] That’s Werner. This is a trophy at the national day in Georgia, Atlanta. Fox: What does it say? Georgia. It says “a replica of the clubhouse, Augusta . . .” Sebring: The masters golf trophy. It’s a replica of the clubhouse and I went down one time, some friends of a sale’s guy was a member and it was totally. . . the columns were all bent, the 14 roof had collapsed, they ended up having to take it out to the awards at the 18 green 20 when the tournament was over, and they just misused it, absolutely misused it. This guy took it all apart. It’s all apart there. The columns were off, they were all sterling and he put it back together. Fox: So this was a clubhouse? [44.49] Sebring: This was a clubhouse at the Georgia national. Fox: That’s amazing. Sebring: [laughs] It IS amazing! Fox: It’s so intricate; there are all these little tiny details. Sebring: Yeah and all, [45] the gallery all the way around. The windows, that’s all - the shutters - that’s all sterling. And the shingles, and this guy did it. That’s Werner. Good man. [taps on table and smiles] yeah. That’s this guy right here [pointing to contact list]. Fox: Thank you. So did Gorham make a lot of trophies like that? Sebring: A lot of trophies, yup. Yup. Fox: That’s so neat. Sebring: Made the Borg-Warner for the Indianapolis 500. If you’d like any of this stuff . . . this is, this is an old. . . this is our company publication, Perspective. Can you take a picture of that? Fox: Yeah, do you mind if I just put it down here and I’ll take it like this? Yeah, this is great. Thank you so much! [Takes picture] That’s beautiful. Sebring: And if you’re talking to any of these guys, let them know that you talked to me. Fox: Thank you. [46.18] Sebring: [Brings out postcard with image of Casino on it, Figure 4.] My daughter found it someplace, she knew I’d be interested and so I had it blown up and . . . Fox: What does this say, I will close . . .? Sebring: I don’t know, I can’t read it. Fox: Something . . . Sebring: Is there a date on the postmark? Fox: No, I don’t think it was ever postmarked. Sebring: Maybe. 15 Fox: Wow. That’s very neat. Sebring: [Laughs] Fox: Where did she find that, I wonder? Sebring: I think she found it on the internet. Fox: That’s great. It seems like you had a lot of good memories in that building. Sebring: Yes. As I say, it just saddens me that I couldn’t have done more to hold it together but . . . [47.09] Fox: No one person can . . . Sebring: It was impossible I guess. Not for me. You know, a lot of guys from Textron would come in and you’d think that things are going to change. They’re smart guys, there’s no question about that. Good, smart guys, but had no feeling for our product. None. None at all. So. . . Fox: We’ve talked about, I feel like we’ve had a great summary of so many different moments in the history of the factory. We talked about the unions, and we talked about when Gorham started to, to outsource, sort of, I don’t know if that was the term, but going to Asia. You were talking about the shift towards the end and how creativity . . . Sebring: Hope it helped. Fox: Yeah, this was great. Thank you. [End of Interview] [Note: After the official interview had ended, Sebring began to tell an additional story that he agreed to record. The transcript for this story is below. The audio for this excerpt is also included in addition to the official interview] 16 [Begin additional excerpt] Well, I’ve always felt that Codman had a lot of help with his work. It’s one thing to sketch on paper, but it’s quite another thing to take that two dimensional design and not only make it 3 dimensional but also put that into silver, silver hollowware. I just feel that he had some, some good guys behind him that, that . . . fantastic designer but also he had some fantastic silversmiths and chasers. Fox: Yeah, and I’m sure it was an interesting mix of people, too. Sebring: There were guys from France, chasers from France. Silversmiths from England. They were quality, quality craftspeople. Fox: Have you seen the Gorham desk, the one that . . . Sebring: Oh, yeah. Fox: I imagine that when you see it you think of things that are different from when I see it. Sebring: Well, I think of the craftsmanship. I mean it’s unbelievable. The inlay, no one could do that today. I don’t think there’s a . . . couldn’t be replicated, I don’t think. No. Fox: Well, thank you. [End additional excerpt] 17 Images Figure 1 Burr Sebring's Office Space Figure 2 Sebring's current flatware projects, in process. 18 Figure 3 Perspective Magazine with featured trophy Figure 4 The Casino at Gorham, image is a blown up version of the postcard Sebring's daughter gave him. 19