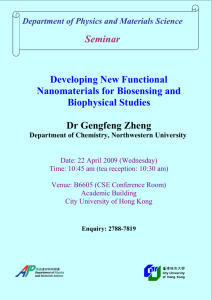

Course File

advertisement

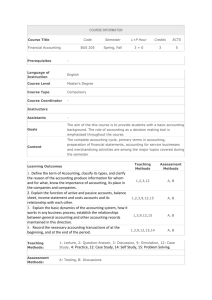

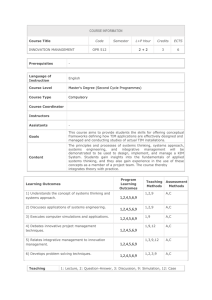

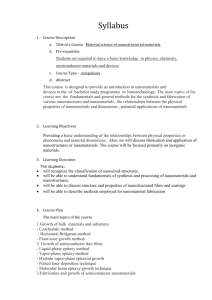

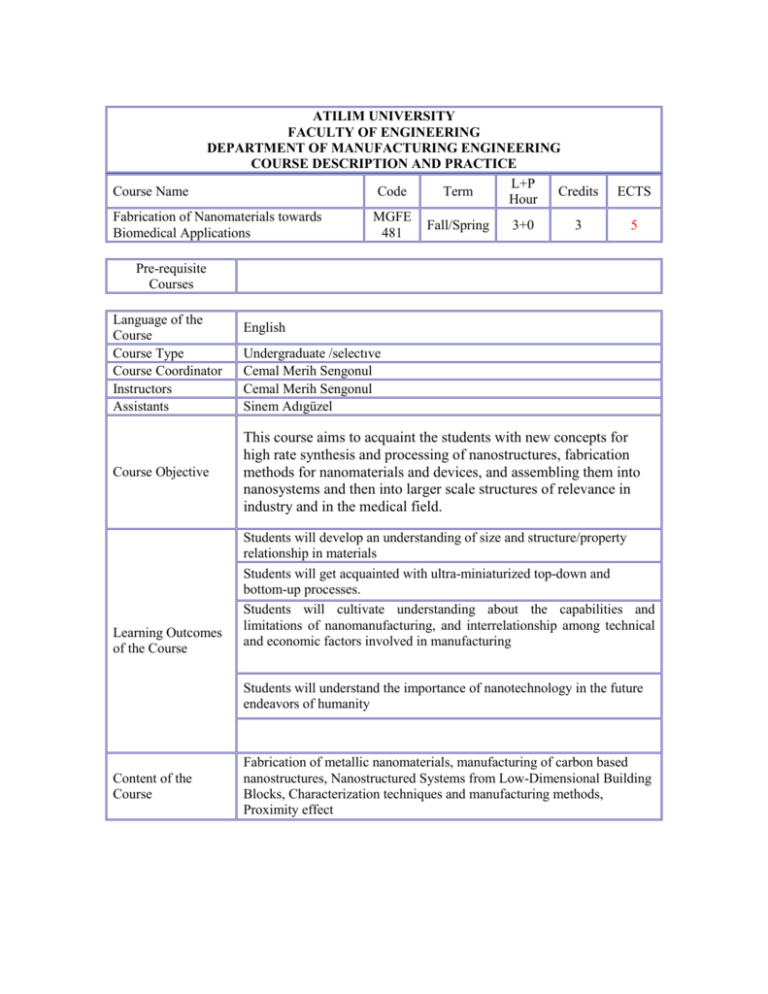

ATILIM UNIVERSITY FACULTY OF ENGINEERING DEPARTMENT OF MANUFACTURING ENGINEERING COURSE DESCRIPTION AND PRACTICE L+P Course Name Code Term Credits Hour Fabrication of Nanomaterials towards MGFE Fall/Spring 3+0 3 Biomedical Applications 481 ECTS 5 Pre-requisite Courses Language of the Course Course Type Course Coordinator Instructors Assistants Course Objective Learning Outcomes of the Course English Undergraduate /selectıve Cemal Merih Sengonul Cemal Merih Sengonul Sinem Adıgüzel This course aims to acquaint the students with new concepts for high rate synthesis and processing of nanostructures, fabrication methods for nanomaterials and devices, and assembling them into nanosystems and then into larger scale structures of relevance in industry and in the medical field. Students will develop an understanding of size and structure/property relationship in materials Students will get acquainted with ultra-miniaturized top-down and bottom-up processes. Students will cultivate understanding about the capabilities and limitations of nanomanufacturing, and interrelationship among technical and economic factors involved in manufacturing Students will understand the importance of nanotechnology in the future endeavors of humanity Content of the Course Fabrication of metallic nanomaterials, manufacturing of carbon based nanostructures, Nanostructured Systems from Low-Dimensional Building Blocks, Characterization techniques and manufacturing methods, Proximity effect WEEKLY SCHEDULE AND PRE-STUDY PAGES Week Topics Pre-study Pages Synthetic Approaches to Metallic 1 Nanomaterials 2 3 4 5 6 Wet chemical preparations, electrochemical synthesis Decomposition of Low-Valency Transition Metal Complexes, particle size separations Structure of carbon nanomaterials, Fullerenes, carbon nanofibers, carbon nanotubes Fabrication of Carbon nanotubes, arcdischarge method, laser ablation, CVD Fabrication of Carbon nanotubes, arcdischarge method, laser ablation, CVD Carbon based materials on biomedical 7 applications, biosensors Room temperature nano-imprint and nano- 8 contact technologies 9 X-ray and electron beam lithography 10 X-ray and electron beam lithography 11 Nano machining 12 13 14 Bio-mimetic and bio-molecular recognition assembly, template assisted assembly, electric-field induced assembly, Langmuirblodgett techniques, Collagen structural hierarchy, Extracellular Matrix and Collagen Mimics in Tissue Engineering Inorganic binding peptides via combinatorial biology 15 Nanomanufacturing processes using polymeric materials 16 Final Course Book SOURCES Nano the Essentials, T. Pradeep, McGraw Hill [1] C. S. S. R. Kumar, J. Hormes, C. Leuschner, Nanofabrication Towards Other sources Biomedical Applications: Techniques, Tools, Applications, and Impact, Wiley-VCH (2005) [2] Mark J. Jackson, Micro and Nanomanufacturing, Springer, 2007 EVALUATION SYSTEM IN-TERM STUDIES Mid-terms Quizzes Assignment Participation QUANTITY 2 >5 2 5 TOTAL CONTRIBUTION OF IN-TERM STUDIES TO OVERALL GRADE CONTRIBUTION OF FINAL EXAMINATION TO OVERALL GRADE TOTAL Course Category Mathematics and Basic Science Engineering Expertise/Skill Courses Engineering Design PERCENTAGE 30 5 30 5 70 70 30 100 % 50 % 40 % 50 % 30 CORRELATION BETWEEN COURSE LEARNING OUTCOMES AND PROGRAM COMPETENCIES Percentage No Program Competencies 1 2 3 4 5 An ability to apply knowledge in mathematics and basic sciences and 1 x computational skills to solve manufacturing engineering problems 2 An ability to define and analyze issues related with manufacturing technologies 3 An ability to develop a solution based approach and a model for an engineering problem and design and manage an experiment x x 4 5 6 7 8 An ability to design a comprehensive manufacturing system based on creative utilization of fundamental engineering principles while fulfilling sustainability in environment and manufacturability and economic constraints An ability to chose and use modern technologies and engineering tools for manufacturing engineering applications An ability to utilize information technologies efficiently to acquire datum and analyze critically, articulate the outcome and make decision accordingly An ability to attain self-confidence and necessary organizational work skills to participate in multi-diciplinary and interdiciplinary teams as well as act individually An ability to attain efficient communication skills in Turkish and English both verbally and orally 9 An ability to reach knowledge and to attain life-long learning and selfimprovement skills, to follow recent advances in science and technology 10 An awareness and responsibility about professional, legal, ethical and social issues in manufacturing engineering 11 12 x x x x x x x An awareness about solution focused project and risk management, enterpreneurship, innovative and sustainable development An understanding on the effects of engineering applications on health, social and legal aspects at universal and local level during decision making process x x TABLE OF ECTS / WORKLOAD Activities Course Duration (Including the exam week: 16x Total course hours) Hours for off-the-classroom study (Pre-study, practice) Assignments Mid-terms Final examination Total Work Load Total Work Load / 30 ECTS Credit of the Course QUANTITY Duration Total (Hour) Workload 16 3 48 16 2 2 1 4 15 3 2 64 30 6 2 150 5