Sputtered nanocrystalline TiC / amorphous C thin films for medical

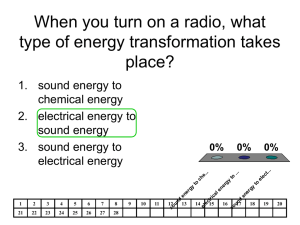

advertisement

Sputtered nanocrystalline TiC / amorphous C thin films for medical applications Nikolett Oláh1, Levente Illés1, Attila Sulyok1, Miklós Menyhárd1, Csaba Balázsi2, Mónika Furkó2, Katalin Balázsi1 1 Thin Film Physics Department, Institute for Technical Physics and Materials Science, Research Centre for Natural Sciences, Hungarian Academy of Sciences, Konkoly-Thege M. str. 29-33, 1121 Budapest, Hungary 2 Institute for Materials Science and Technology, Bay Zoltán Nonprofit Ltd for Applied Research, Fehérvári str. 130, 1116 Budapest, Hungary *olah.nikolett@ttk.mta.hu Titanium and titanium alloys are preferred for implants for their good properties as corrosion resistance, biocompatibility, durability and strength. Biomaterials must be nontoxic, non-carcinogenic, chemically inert, stable and mechanically strong enough to withstand the repeated forces of a lifetime. Nanocomposite coatings consisted of nanocrystalline grains and amorphous matrix promises possibility of synthesizing a surface protection layer. The combination process of Ti and C is relatively easy and cheap, and at the same time TiC possesses good mechanical properties. Sedlackova et al. usually deposited TiC based nanocomposites by magnetron sputtering from Ti and C targets in air ambient [1] because the vacuum deposition provides great flexibility for manipulating material chemistry and structure, resulting in films and coatings with special properties [2]. Due to this fact, the correlation between the structural, corrosion and biological properties of TiC / amorphous C (TiC/a:C) thin films prepared by dc magnetron sputtering was examined. Nanocomposite thin films were deposited on various substrates (Ti 6Al 4V alloy, CoCrMo alloy, Si/SiO2) in argon at 25 C° and 0.25 Pa. The input power of carbon target was 150 W, while the input power of titanium target was 50 W. The structure of the thin films was investigated systematically by Transmission Electron Microscopy (TEM), High Resolution Electron Microscopy (HREM), Scanning Electron Microscopy (SEM) and X-Ray Diffraction (XRD). X-ray Photoelectron Spectroscopy (XPS) was used for matrix characterization, while the corrosion resistance of films was measured in various pH solutions. Properties (e.g. physical or mechanical) can be improved by the introduction of boundaries or particles of hard phases for stopping deformation. The figure shows that thin films consist of nanometer-sized columnar TiC crystallites embedded in carbon matrix. The Selection Area Electron Diffraction (SAED) confirmed the presence of the cubic TiC phase. Cross-sectional TEM image of TiC / a:C thin films prepared at 40 W of Ti power. (SAED in details confirmed the cubic TiC phase). (Oláh et al [3]) References [1] Sedláčková K., Ujvári T., Grasin R., Lobotka P., Bertóti I., Radnóczi G., 2008, C-Ti nanocomposite thin films: Structure, mechanical and electrical properties, Vacuum, 82, 214-216. [2] Balázsi K., Vandrovcová M., Bačáková L., Balázsi C., Bertóti I., Davin F. and Radnóczi G., 2013, Mechanical behavior of bioactive TiC nanocomposite thin films, Mater SCi Forum, 729, 296-301. [3] Oláh N., Veres M., Sulyok A., Menyhárd M., Gubicza J., Balázsi K., 2013, Examination of nanocrystalline TiC/amorphous C deposited thin films, J Eur Ceram Soc, Submitted. Acknowledgement This work was supported by OTKA Postdoctoral grant Nr. PD 101453, the János Bolyai Research Scholarship of the Hungarian Academy of Sciences. The research leading to this result has received funding for European Community Seven Framework Programme FP7/2007-2013 under grant agreement Nr. 602398 (HypOrth). Nikolett Oláh thanks to FIKU.