Session V

GOOD VIBRATIONS: PHYSICS OF THE ACOUSTIC GUITAR

Jamie Darken

American University

4400 Massachusetts Ave. NW, Washington, DC. 20016, jd8493a@student.american.edu

class stigma as musicians gained the ability to travel and

Abstract – Although the acoustic guitar has played a major play for larger and more public audiences [3].

It is important to understand the history behind modern

role in musical cultures for centuries, its basic design and

construction material has remained largely unchanged. This guitar culture and its resistance to change before addressing

paper examines the physics of the acoustic guitar, alternative construction materials. Equally important,

specifically waves and vibrations, to explain how the however, is understanding how an acoustic guitar works in

instrument produces musical sound. Each major part of the order to analyze the benefits of synthetic materials.

guitar is examined, following the path of vibrations that start

ACOUSTIC GUITAR FUNDAMENTALS

in the strings and move through the soundboard to the body.

This understanding of guitar construction is extended in an

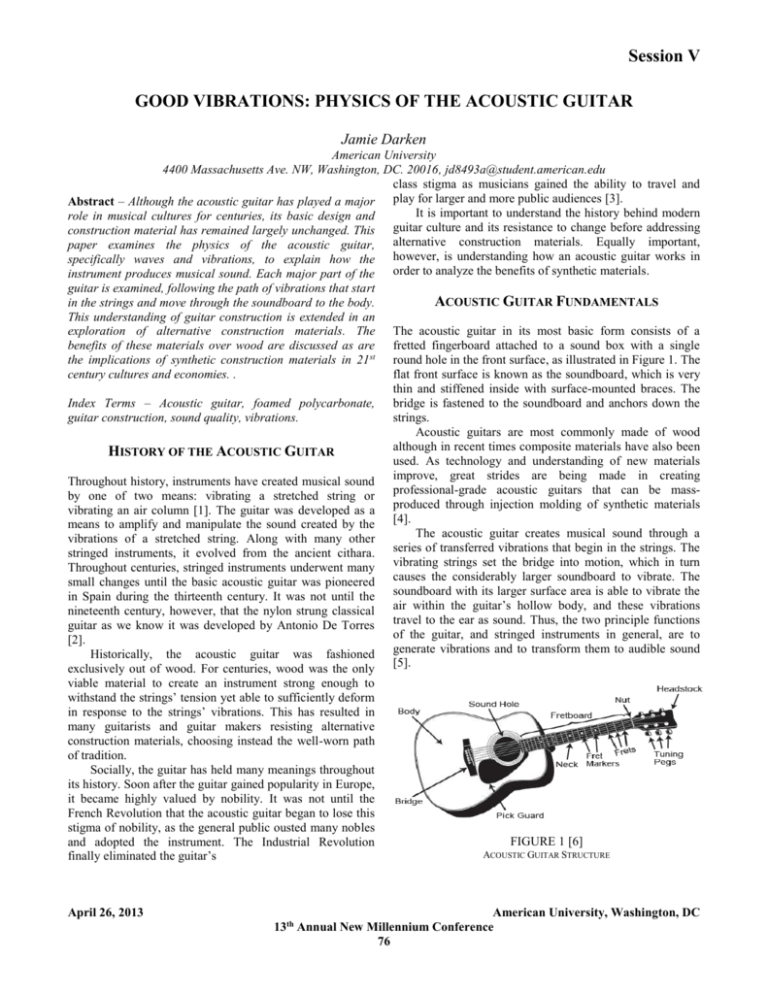

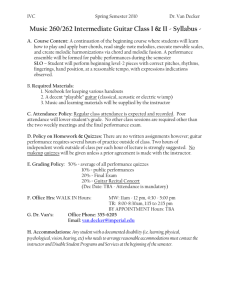

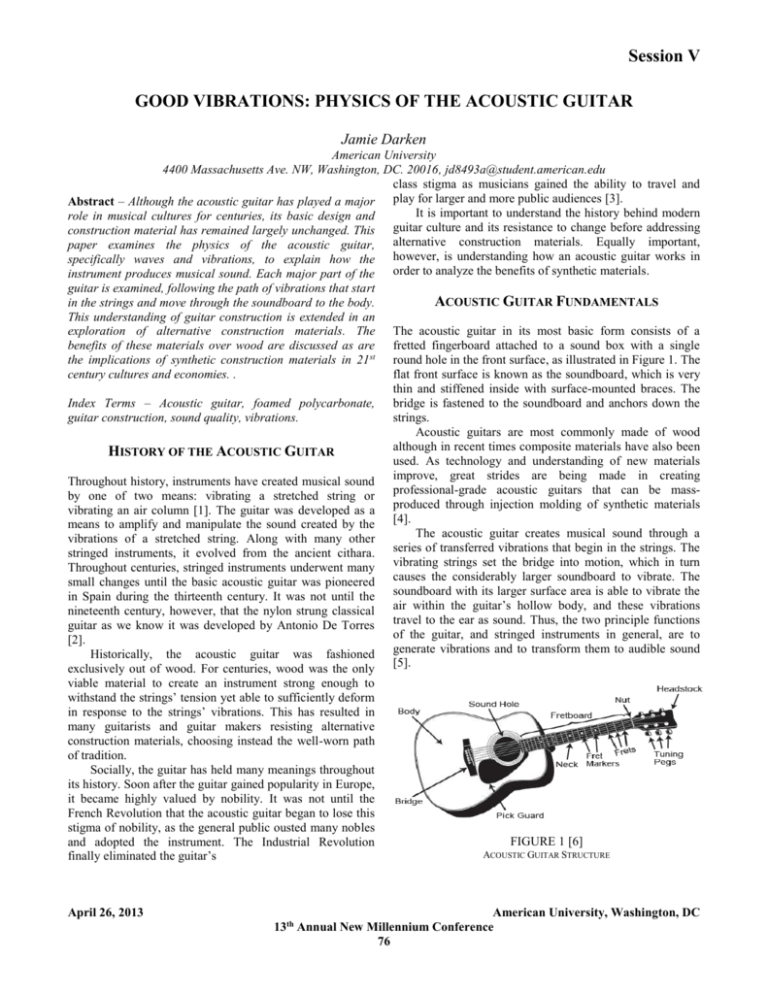

exploration of alternative construction materials. The The acoustic guitar in its most basic form consists of a

benefits of these materials over wood are discussed as are fretted fingerboard attached to a sound box with a single

the implications of synthetic construction materials in 21 st round hole in the front surface, as illustrated in Figure 1. The

century cultures and economies. .

flat front surface is known as the soundboard, which is very

thin and stiffened inside with surface-mounted braces. The

Index Terms – Acoustic guitar, foamed polycarbonate, bridge is fastened to the soundboard and anchors down the

guitar construction, sound quality, vibrations.

strings.

Acoustic guitars are most commonly made of wood

although

in recent times composite materials have also been

HISTORY OF THE ACOUSTIC GUITAR

used. As technology and understanding of new materials

Throughout history, instruments have created musical sound improve, great strides are being made in creating

by one of two means: vibrating a stretched string or professional-grade acoustic guitars that can be massvibrating an air column [1]. The guitar was developed as a produced through injection molding of synthetic materials

means to amplify and manipulate the sound created by the [4].

The acoustic guitar creates musical sound through a

vibrations of a stretched string. Along with many other

series

of transferred vibrations that begin in the strings. The

stringed instruments, it evolved from the ancient cithara.

vibrating

strings set the bridge into motion, which in turn

Throughout centuries, stringed instruments underwent many

causes

the

considerably larger soundboard to vibrate. The

small changes until the basic acoustic guitar was pioneered

soundboard

with its larger surface area is able to vibrate the

in Spain during the thirteenth century. It was not until the

air

within

the

guitar’s hollow body, and these vibrations

nineteenth century, however, that the nylon strung classical

travel

to

the

ear

as sound. Thus, the two principle functions

guitar as we know it was developed by Antonio De Torres

of

the

guitar,

and

stringed instruments in general, are to

[2].

generate

vibrations

and to transform them to audible sound

Historically, the acoustic guitar was fashioned

[5].

exclusively out of wood. For centuries, wood was the only

viable material to create an instrument strong enough to

withstand the strings’ tension yet able to sufficiently deform

in response to the strings’ vibrations. This has resulted in

many guitarists and guitar makers resisting alternative

construction materials, choosing instead the well-worn path

of tradition.

Socially, the guitar has held many meanings throughout

its history. Soon after the guitar gained popularity in Europe,

it became highly valued by nobility. It was not until the

French Revolution that the acoustic guitar began to lose this

stigma of nobility, as the general public ousted many nobles

and adopted the instrument. The Industrial Revolution

finally eliminated the guitar’s

April 26, 2013

FIGURE 1 [6]

ACOUSTIC GUITAR STRUCTURE

American University, Washington, DC

13th Annual New Millennium Conference

76

Session V

Given these functions, several generalizations about

good guitar design can be made. The strings must be

uniform flexible so that they create consistent vibrations. In

addition, the guitar itself must have rigid supports that can

withstand the enormous tension of the strings, but these

supports and the body must also be able to deform in

response to the strings’ vibrations without warping over

time. These design characteristics all have their roots in one

area of physics: waves and sound.

WAVES AND SOUND

To understand the physics of the acoustic guitar, it is first

necessary to understand how waves and sound generally

behave. A mechanical wave is defined as a disturbance

propagated through a material medium [7]. There are two

main types of mechanical waves: transverse and

longitudinal. Transverse waves are created when the motion

of the medium’s particles is at right angles to the motion of

the wave as seen in Figure 2 [8]. Longitudinal waves are

created when the particles of the medium move in the same

direction of the wave. As the particles move, they go

through a series of compressions and rarefactions, which

constitutes the wave [9].

In terms of wave motion, simple harmonic motion lies

at the heart of musical sound. Simple harmonic motion

(SHM) has two key characteristics: the motion takes place

symmetrically about an equilibrium position and the motion

repeats itself in a definite time interval [13]. It is specifically

SHM that allows instruments to create musical sound waves.

An important characteristic of general wave motion, in

this case specifically SHM, is frequency, or how often a

vibration occurs. Frequency is measured in hertz (Hz),

which is the number of vibrations per second. When

musicians refer to musical notes like A or F sharp, they are

referring to a specific frequency that their instrument is

producing. There are many different patterns of string

tunings for acoustic guitars, but the most common tuning is

expressed in both frequency and note in Table I.

TABLE I

FUNDAMENTAL FREQUENCIES OF GUITAR STRINGS

String

1

2

3

4

5

6

Note

E2

A2

D3

G3

B3

E4

Frequency

82

110

147

196

247

330

Another important characteristic is wavelength, or the

distance between two crests of a wave. Wavelength and

frequency together relate to the speed of the wave, given by

v = f

FIGURE 2 [10]

A TRANSVERSE WAVE CREATED BY MOVING A STRING UP AND

DOWN

Sound waves are longitudinal, typically propagating

through air, and the source of sound is a vibrating object. For

example, the tuning fork in Figure 3 is vibrating and causing

the air around it to compress and rarify, thus creating sound

waves [11].

(1)

where v refers to wave speed in meters per second, f

refers to frequency in hertz, and refers to wavelength in

meters.

In relation to the acoustic guitar, these properties of

wave motion can be applied to the SHM of the vibrating

guitar strings, which is where the production of musical

sound begins.

VIBRATIONS IN A STRING

The musical sound of the acoustic guitar is born from the

vibrations of the strings. When a string is plucked, it is set

into periodic motion and vibrations propagate outward from

the point of contact. In the case of the acoustic guitar, these

vibrations reach each fastened end of the string and are

reflected back along the string in the opposite direction. This

creates what is known as a standing wave, as shown in

Figure 4

FIGURE 3 [12]

THE COMPRESSION AND RAREFACTION OF AIR TO CREATE SOUND

April 26, 2013

American University, Washington, DC

13th Annual New Millennium Conference

77

Session V

where v refers to wave speed in meters per second, T

refers to the tension in the string in Newtons, and refers

to the sting’s linear mass density in kilograms per meter.

Linear mass density is given by (3):

.

m

=

L

FIGURE 4 [14]

At certain frequencies, standing waves have important points

called nodes and antinodes at which there is zero

displacement and maximum displacement, respectively [15].

The strings in the guitar will vibrate with several

frequencies at once: the fundamental frequency, determined

by the vibration of the string as a whole, and overtones, or

harmonics, which are created by sectional vibrations [16].

The fundamental frequency of a string in a guitar is the

principal tone that is heard while harmonic overtones give

the sound its timbre, or characteristic color. Each instrument

excites overtones in a unique way depending on factors like

construction material and the manners by which it transfers

vibrations. Differences in timbre between instruments result

in many different possible sounds to be created even as the

instruments play the same note.

FUNDAMENTAL FREQUENCY

Generally, the range of fundamental frequencies that can be

created on an acoustic guitar is 80Hz to 1320 Hz [17]. Using

knowledge of wave behavior and a string’s characteristics

such as length and density, the fundamental frequency of a

given guitar string can be determined [18]. First, the velocity

of a transverse wave in string is given by (2):

v=

April 26, 2013

T

(3)

where m refers to the string’s mass in kilograms and L

refers to its length in meters. Since a vibrating guitar string

end

has a node at each

where it is fastened, it can be

determined that the fundamental standing wave in the string

has a wavelength that is twice the length of the

string. Thus,

it is possible to equate (2) to (1) and determine a general

equation for the fundamental frequency of a string in (4):

f=

A STANDING WAVE’S FUNDAMENTAL FREQUENCY AND OVERTONES

1 T

2L

(4)

This equation sheds light on the relationship between

the characteristics of a string and that string’s fundamental

(4) shows that longer and denser strings

frequency. Equation

will have a lower fundamental frequency since larger values

for L and in the denominators will result in a smaller

quotient. Additionally, higher tension in the string will result

in a higher fundamental frequency produced since a larger

value for T will result in a larger quotient. These

relationships explain why the guitar is played by holding

down the strings at the frets. In doing so, the performer is

shortening the length of the string while keeping every other

characteristic constant, thus raising the fundamental

frequency that is heard. The fundamental frequency alone,

however, does not make up the full sound of an acoustic

guitar.

OVERTONES

In addition to the fundamental frequency, a number of

higher frequencies at integer multiples of the fundamental

will also occur as a result of specific sections of the guitar

string vibrating on their own in different ways. These higher

frequencies are known as overtones. Thus, the sound made

by an acoustic guitar is a complex tone. According to

Fourier’s theorem, this complex tone can be thought of as

the sum of many pure tones of varying amplitudes, as

illustrated in Figure 5 [19]. In this case, it is the sum of the

fundamental frequency and its overtones.

(2)

American University, Washington, DC

13th Annual New Millennium Conference

78

Session V

FIGURE 5 [20]

HOW THE FUNDAMENTAL FREQUENCY AND OVERTONES CREATE A

COMPLEX TONE

It is these overtones that give the acoustic guitar, and any

other instrument, its sound quality, or timbre.

The timbre, or characteristic color, of the guitar’s sound

can be affected by the location of the pluck. When plucked

near the middle, the fundamental frequency vibrates with

higher amplitude than do the overtones, giving the tone a full

and lower sound. However, when plucked near the end,

higher harmonics are more strongly excited, which gives the

guitar a bright and brassy sound [21].

Strings are not only the source of the vibrations that

create musical sound in a guitar, but they can affect the

guitar’s sonic character. The next step in the production of

musical sound in an acoustic guitar has an even larger

impact on the overall sound quality of the guitar itself.

the soundboard transfers sufficient amplitude to be heard.

Likewise, the soundboard should have a smooth response; it

should accurately convey the relative levels of the

fundamental frequency and the overtones.

The soundboard also provides structural support. When

perfectly in tune according to Table I, the tension in the

strings is about 1000N. The soundboard must be able to

withstand this force yet still be able to be forced to vibrate

by the strings. Thus, a high stiffness to mass ratio is desired;

a good soundboard should be very stiff to prevent warping

or breaking but it should have as little mass as possible in

order to more easily be set into motion by the strings’

vibrations [23].

To prevent an actual collapse of the material while still

maintaining desirable acoustic properties, various patterns of

wooden reinforcements have been designed for the

soundboard. These reinforcements are called bracing.

BRACING

A crucial aspect of the soundboard is the underside bracing.

In almost every acoustic guitar, pieces of wood are glued to

the bottom of the soundboard within the body of the guitar.

This bracing serves a dual function: to provide structural

support and to improve tonal quality. The most common

bracing pattern is known as ‘X’ bracing seen in Figure 6.

THE SOUNDBOARD

The next step in the sequence of the production of musical

sound by an acoustic guitar is the soundboard. The

soundboard is the 2-3mm thin, flat front surface of the

guitar. It is the soundboard’s job to receive and to amplify

the strings’ vibrations. As it is set into motion, it increases

the amount of air that is also set into vibration. The

soundboard achieves significant amplification due to its

large surface area.

It is largely agreed upon by guitarists and guitar makers

that the soundboard is the most important characteristic of

the acoustic guitar in terms of the creation of a good tone

[22]. Also, the soundboard provides a crucial structural

function since it must support the tension of the strings.

In terms of guitar tone, a good soundboard should fulfill

needs relating to timbre, projection, and response. Although

timbre is perhaps the most important aspect of a good tone,

different timbres are desired for different types of guitar

playing. Therefore, timbre is highly subjective; there is no

single best timbre for a good soundboard to achieve.

Projection refers to the loudness of the guitar. Since the

soundboard dramatically increases the surface area that

forces the air to vibrate, it is important that in this process

April 26, 2013

FIGURE 6 [24]

AN ‘X’ BRACING PATTERN

Most woods chosen for their superior tonal qualities,

such as spruce and cedar, are not strong enough to withstand

the 1000N tension of the strings. These woods’ weakness

lies in their across grain fragility [25]. Although the wood

may be strong enough to support the string tension parallel

to its grain, the tension will cause warping and damage in

the direction perpendicular to the wood grain. Due to its

shape, X bracing provides stiffness in both directions and

significantly strengthens the soundboard.

In terms of sound quality, pieces of wood, or sound

bars, are used to divide the soundboard into different

sections and to transfer vibrations from the bridge to these

American University, Washington, DC

13th Annual New Millennium Conference

79

Session V

different sections. Each of these different sections can be

thought of as a mini soundboard, each one with a different

resonant frequency. The purpose of these mini soundboards

is to affect how the overtones of the guitar sound. Different

overtones can be better heard as they excite the mini

soundboards.

The pattern of sound bar placement is a highly debated

topic amongst guitarists and guitar makers since it can have

drastic effects on the guitar’s timbre and sound quality. For

example, Antonio Torres’ design, which is still commonly

used, consists of seven long and flexible sound bars arranged

in a fan shape that pass over the bridge as seen in Figure 7.

On the other hand, the Kasha design relies on many short

and stiff sound bars that emanate from the bridge. In the end,

the personal taste of the guitarist and guitar maker play a

large part in the bracing design [26].

Resonance refers to the creation of large vibrations in a

body by relatively small periodic forces that are in step with

the natural frequency of the body [28]. A body’s natural

frequency is the frequency that requires the least amount of

energy to force the body to vibrate. In the case of the

acoustic guitar, the small periodic forces are the forced

vibrations in the soundboard and the resonating body is the

air within the guitar. Due to the air’s relatively high volume,

this air is excited mostly by the lower frequencies of the

guitar.

FIGURE 8 [29]

A BASIC HELMHOLTZ RESONATOR

FIGURE 7 [27]

TORRES’ BRACING DESIGN

Although the soundboard plays a major role in the guitar’s

sound quality, it is still not enough to produce musical sound

at a sufficient volume. The vibrations must go through one

last step, the body, before they become what we know as the

sound of a guitar.

THE BODY: A HELMHOLTZ RESONATOR

The body of the guitar is the hollow cavity that the

soundboard covers. As the soundboard vibrates, it forces the

air within the body to vibrate as well, thus producing the

sound of the acoustic guitar. The body serves to increase the

loudness of the sound through a principle known as

resonance.

April 26, 2013

The body of an acoustic guitar can be classified as a

specific type of resonator: a Helmholtz resonator, as seen in

Figure 8. Helmholtz resonators consist of a container with

one or two openings, the smaller of which is called the neck.

As the air within the container is forced to vibrate, it acts

like a spring on the mass of the air in the neck. When the

natural frequency of the air in the container is matched, it

will greatly excite the air in the neck, thus creating a

relatively loud sound.

In the case of the acoustic guitar, the sound hole acts as

the neck. As the air inside the body is forced to vibrate by

the soundboard, it acts as a spring on the air around the

sound hole and pushes it in and out in time with the

vibrations. In this way, even more air is forced to vibrate at

the frequency transferred from the soundboard to the air

inside the body.

The air inside the body is crucial, but it is also important

to consider the material that makes up the body itself.

American University, Washington, DC

13th Annual New Millennium Conference

80

Session V

ALTERNATIVE CONSTRUCTION MATERIALS

Historically, the acoustic guitar has been exclusively

fashioned out of wood. This trend continues even today,

with the most popular construction materials for acoustic

guitars being coniferous softwoods like alpine spruce, sitka

spruce, adriondack spruce, and western red cedar [30]. These

types of wood are valued for their inherent acoustic

qualities, although little is understood about the precise

relationship between acoustics and the wood’s nature.

With recent technological developments, efforts have

been made to use synthetic materials to mimic the strengths

of wood as a guitar construction material while rectifying its

weaknesses. Several synthetic materials that are gaining

popularity in acoustic guitar construction are high pressure

laminate, which is a wood composite, and carbon fiber

plastic. These materials are sufficiently rigid, yet

simultaneously able to deform, to make bracing superfluous.

One type of alternative construction material, foamed

polycarbonate, is beginning to redefine understanding of the

ideal construction material. A guitar with a foamed

polycarbonate soundboard can be seen in Figure 9.

Specifically, foamed polycarbonate has shown that a high

stiffness to mass ratio is not necessarily a requirement for

desirable guitar tone and structure. Rather, the

microstructure of the material probably plays a larger role

than previously thought in affecting the acoustics of the

guitar. This is evidenced by the fact that another material,

foamed polyvinylchloride, with a stiffness to mass ratio

similar to that of foamed polycarbonate was considered

“acoustically dead” in tests [31].

Foamed polycarbonate exhibits several desirable

characteristics in terms of acoustic guitar design.

Acoustically, it has been found to sound similar to cedar,

and thus it reaches the high tonal quality achieved by this

type of wood. Additionally, this material has particularly

strong bass response. Structurally, it lacks the cross-grain

weaknesses of wood and thus provides a stronger and more

reliable guitar. Finally, foamed polycarbonate performs well

in a wide range of temperatures and is resistant to changes in

humidity. Wood, on the other hand, is notorious for warping

in response to changes in temperature and humidity. In this

way, foamed polycarbonate rectifies several weaknesses of

wood as a material for acoustic guitars.

While the possibilities of synthetic materials such as

foamed polycarbonate are beginning to be explored, there is

still much to learn before such materials can be practically

deployed. At this point, experimentation with alternative

construction materials is a crucial step towards developing

guitars in the future.

April 26, 2013

FIGURE 9 [32]

A GUITAR WITH A FOAMED POLYCARBONATE SOUNDBOARD

THE FUTURE OF GUITAR DESIGN

In relation to the world’s economy, synthetic materials can

revolutionize how guitars are constructed and distributed

across the globe. As the popularity of the instrument

continues to grow, a physical analysis of guitar construction

can give crucial insight into how to more effectively

construct guitars, thus bringing the guitar into the 21 st

century in terms of technology and economics.

Historically, the construction of acoustic guitars was left

to highly skilled artisans called luthiers. Luthiers’ guitar

designs, although intricate and refined, were based

exclusively on trial and error.

Today, as the world’s population has grown in tandem

with the popularity of the guitar, acoustic guitar production

has largely been relegated to the factories of East Asian

countries. A focus on mass production as well as a lack of

acoustic guitar knowledge has resulted in the proliferation of

entry-level acoustic guitars that not only sound inferior but

are difficult to play.

Guitar makers are exploring ways to create high quality

synthetic-material guitars that fit the tastes of musicians

while also conforming to the high production demands of the

modern world. Specifically, materials like foamed

polycarbonate are suitable for injection molding, which is

ideal for factory production as it is fast and does not require

intimate knowledge of delicate shaping of wood.

American University, Washington, DC

13th Annual New Millennium Conference

81

Session V

SUMMARY

Although the acoustic guitar has existed for centuries, its

design has hardly changed. This stagnation is due in part to

cultural taste as well as a lack of technical knowledge of the

physics of guitar construction and sound production.

Today, advanced understandings of physics have

surpassed the previous trial-and-error method of guitar

design. Physics can be used to bring the guitar into the 21 st

century while not violating cultural taste in terms of

desirable guitar tone.

The best way to accomplish this is through the

exploration of alternative construction materials for acoustic

guitars. Although the exact effects of microstructure on the

acoustics of the guitar are not well understood, it has been

discovered that the makeup of the material may have a

significant effect on its tonal quality. In this way,

technological advances in the production of synthetic

materials can offer a way to produce inexpensive, high

quality acoustic guitars, thus moving an ancient and beloved

tradition into the future.

6D1FDCAD-5AC2-43EA8B7865D5B71A8709&Image_Type=image.

[25] Ref. 2.

[26] Eendebak, B, “The Soundboard.” Design of a Classical Guitar. 2011.

Web. 27 Feb. 2013.

http://designofaclassicalguitar.com/soundboard.php.

[27] “How to Build a Guitar – Part 4. Bracing the Soundboard.” Gideon’s

Guitar Pages. 2013. Web. 27 Mar. 2013.

http://gidsguitars.wordpress.com/how-to-build-a-guitar-part-4bracing-the-soundboard.

[28] Ref. 11.

[29] “File: Helmholtz resonator.jpg.” Wikimedia Commons. 8 Nov. 2012.

Web. 10 Apr. 2013.

http://commons.wikimedia.org/wiki/File:Helmholtz_resonator.jpg

[30] Ref. 2.

[31] Ref. 2.

[32] “The Guitar: Overview.” Secret Valentine. 2012. Web. 28 Mar. 2013.

http://www.coolacoustics.com/sv/overview.php?CurrentSection=over

view

REFERENCES

[1] Rigden, John S, Physics and the Sound of Music, New York: Wiley,

1977.

[2] Armstrong, Rob and Eddie Norman and Owain Pedgley, “MaterialsInspired Innovation for Acoustic Guitar Design”, METU Journal of

the Faculty of Architecture, Vol. 26, No. 1, 2009, pp. 157-175.

[3] Findlay, Sharon. “The Evolution of the Guitar.” Faze, Faze. 2013. Web.

28 Mar. 2013.

http://www.faze.ca/issue04/evolution_of_the_guitar.html.

[4] Ref. 2

[5] White, Donald H and Harvey E White, Physics and Music: The Science

of Musical Sound, Philadelphia: Saunders College, 1980.

[6] “Need to Know the Parts of the Acoustic Guitar?” Guitar on the Spot.

On the Spot Publishing. Web. 21 Feb. 2012. http://www.guitar-on-thespot.com/image-files/acousticguitar.gif.

[7] Ref. 1.

[8] Hewitt, Paul G, Conceptual Physics, 11th ed. San Francisco: Pearson

Addison Wesley, 2010.

[9] Ref. 5.

[10] Ref. 8.

[11] Ref. 1.

[12] Ref. 8.

[13] Ref. 1.

[14] Ref. 8.

[15] Ref. 5.

[16] Lloyd, LI. S, Music and Sound, London: Oxford University Press:

1937.

[17] French, M and D. Hosler, “The Mechanics of Guitars”, Experimental

Techniques, Vol. 25, No. 3, 2001, pp. 45-48.

[18] Stewart, George W, Introductory Acoustics, New York: Van Nostrand,

1932.

[19] Ref. 5.

[20] Ref. 8.

[21] Ref. 5.

[22] Ref. 2.

[23] Ref. 2.

[24] Somogyi, Ervin, “What Makes an Acoustic Tick?” Premier Guitar.

2013. Web. 22 Feb. 2013.

http://www.premierguitar.com/Stream/StreamImage.aspx?Image_ID=

April 26, 2013

American University, Washington, DC

13th Annual New Millennium Conference

82