Sample Machine Shop - University of Maine

Department: The University of Maine System

Document: Department Annual Safety Training Checklist

Page 1 of 3

10/19/15

Department

Department Annual Safety Training Checklist

Sample Machine Shop

The area supervisor or their designee must conduct the required training on the following items on an annual basis. This form will be maintained by the supervisor as documentation of training.

Employee Name (print): Employee (signature)

Supervisor (or Designee) Name (print) Supervisor or Designee (signature)

Date

Employee Training Items

1. Discuss the Hazards of the Job.

Review all potential hazards including, but are not limited to:

Physical (noise, moving machinery, hot surfaces, electrical, working from heights, ladders, slipping, falling, moving vehicles/equipment, sharp objects);

Chemical (gases, liquids, flammables, toxics, corrosives, poisons);

Ergonomics (repetitive motion, extreme heat/cold, lifting, vibrations, awkward positions);

Biological (blood, bacteria, viruses);

Hidden hazards: (i.e. asbestos, lead, underground utilities)

Does the employee use any special equipment / tools / vehicles? If so, discuss any hazards and required additional training.

2. If employee uses Personal Protective Equipment (PPE)

Discuss the job tasks that require the use of PPE

Location and availability of PPE and PPE assessment forms

Is the PPE adequate and serviceable?

Supervisor’s Notes

Explain the UMaine Machine Shop Program requirements.- In particular:

Training - All operators are required to be trained and assessed as competent before using any machine tools.

Explain - Users have to be signed off by the supervisor for each individual piece of equipment.

Equipment – explain the equipment types and the restrictions of use

(including lone working) due to hazard, skill level, and operations being conducted.

Physical – Explain the minimum workshop practices.

For example: wearing of hair tied up

Explain any additional practices required by your department.

Chemical – Some chemicals may be used in the workshop. Go over the key Safety Data Sheets (SDS).

Ergonomics (computers) – Anyone that works more than four hours per day at a computer workstation must take on-line workstation training. Go to the UMaine SEM web site.

Ergonomics (Manual Handling) – Operations in the workshop may require moving / lifting heavy loads /vibration / repetitive tasks.

Explain the hazards and the tools / procedures available to mitigate the risks of injury.

Biological – We should not have any biological hazards in our workplace. If someone gets sick, do not attempt to clean it up. Call for a custodian who has been properly training to perform this work.

Hidden Hazards – The most common is indoor air quality. If you have concerns or see areas where there might be moisture present please contact Facilities Management

Explain the requirement to wear safety spectacles at all times.

Machine shop operations require the use of a variety of PPE depending on the equipment being used and the operations being conducted.

Department: The University of Maine System

Document: Department Annual Safety Training Checklist

Page 2 of 3

10/19/15

3. Emergency Action Plans

Location of the Emergency Action Plan

Evacuation procedures, fire alarms, and rally point information

Indicate who is designated and trained to use a fire extinguisher

Indicate who is designated and trained to be the emergency evacuation coordinator

4. If employee uses Chemicals

Location and availability of Material Safety Data Sheets (MSDS) within the work area

Discuss any changes in the chemicals used or precautions required since previous training

Ensure that hazardous chemical training has been completed for all hazardous chemicals unless covered by a current Chemical Hygiene

Plan (CHP)

Discuss any changes to the Chemical Hygiene Plan, for chemicals covered by a CHP

Indicate who is designated and trained to clean up hazardous chemical spills

Discuss Satellite Accumulation Area (SAA) and Universal Hazardous

Waste storage and training requirements. Administrative office workers are not occupationally exposed to hazardous chemicals, but HAZCOM program and SDS’s must be explained. Please take this training on-line by visiting the SEM website.

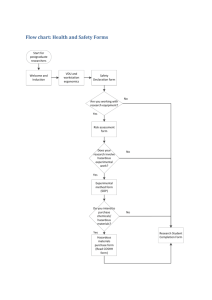

5. Review any additional safety training requirements they may require (review next page with the employee)

A complete listing is located on SEM web page at: http://www2.umaine.edu/SEM/training.htm

Examples of PPE used:

Impact Resistant full face visor (worn over safety spectacles)

Welding face shield / goggles

Heat and or cut resistant gloves

Flame resistant clothing

Toe/metatarsal protection footwear

Respirators

Any other used by your department

Discuss which PPE is used for which function and why.

This office has smoke alarms, it does not have sprinklers (verify), if you hear the alarm, calmly evacuate the building, do not take time to turn off your computer or other devices.

Our emergency action plan is simple, you hear an alarm you leave the building. Stop at you designated mustering area to be accounted for. If you require assistance leaving the building contact your supervisor to develop an action plan.

Our designated emergency evacuation coordinators are

_______________________

Machine shop workers can be occupationally exposed to hazardous chemicals, therefore the HAZCOM program and SDS’s must be explained. Please take this training on-line by visiting the SEM website.

There may be some unique things that you are involved with as employees or volunteers. It is critical that you received specialized training before performing the job tasks. Example: If you would like to extinguish a small fire, you can take Fire Extinguisher training. It requires classroom training and an annual on-line refresher.

Department: The University of Maine System

Document: Department Annual Safety Training Checklist

Page 3 of 3

10/19/15

The following common tasks require additional specialized safety training. Information regarding the frequency of the required training and how to obtain the training is available on the SEM web site at http://www2.umaine.edu/SEM/training.htm

Operating a computer terminal for more than four (4) consecutive hours on a daily basis

Remaining behind and assisting persons in orderly evacuation in an emergency

Using a fire extinguisher in an emergency

Working in areas with exposure to elevated surfaces and fall hazards

Using ladders

Working on scaffolds

Using vehicle mounted elevating work surfaces (telescoping and/or articulating)

Operating a forklift, walker-stacker, or other industrial truck (other than Registered Motor Vehicles)

Using a crane or hoist

Performing service or maintenance on machines or equipment with stored/potential energy (lockout / tagout)

Working with or around electricity

Welding / soldering / brazing

Entering (or overseeing entry into) a confined space

Working in or around trenches/excavations

Using farming/agricultural machines or equipment

Applying pesticides or working in an area that uses pesticides (i.e. farms, greenhouses, nurseries, or forests)

Working in remote areas where there is an absence of prompt medical care (clinic, hospital, etc.)

Operating a watercraft or vessel (either motorized or man-powered)

Conducting tree work (trimming trees) or logging operation

Wearing Personal Protective Equipment (PPE)

Wearing a full body harness

Working around excessive noise levels

Using class 3b or 4 lasers

Handling or using radioactive materials or radiation producing equipment

Performing tasks with exposure to human blood or other regulated bodily fluids (clean up, handle, perform first aid, etc.)

Performing tasks with exposure to respiratory/inhalation hazards such as chemicals, nuisance dusts, asbestos, silica, etc

Using hazardous chemical or cleaning up chemical spills

Working with or around hazardous waste

Handle / store / inspect / ship Universal Waste (such as fluorescent and HID lamps, batteries, mercury containing devices, cathode ray tube televisions and monitors, etc.)

Work with or around Satellite Accumulation Areas (hazardous wastes that are initially generated and tend to accumulate at or near the point of waste generation).

Transporting, packaging, shipping or receiving hazardous materials

It is that simple - review all of the special comments and answer questions, then meet privately with each of your employees and ask who wants to be more involved and more responsibility?

For a more information about Specialized Training Requirements visit the University of Maine Safety and Environmental Management

(SEM) web page at: http://www2.umaine.edu/SEM/training.htm

or contact SEM at 581-4055.