A novel bioreactor for cellular electrical stimulation

advertisement

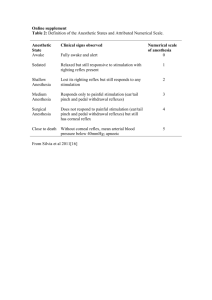

A NOVEL BIOREACTOR FOR CELLULAR ELECTRICAL STIMULATION: DESIGN AND DEVELOPMENT Fabio Zomer Volpato1,2, Enrico Merzari1, Claudio Migliaresi1, Dietmar W. Hutmacher2 1 2 BIOtech Research Center, University of Trento, Trento (TN), Italy Institute of Health and Biomedical Innovation, Queensland University of Technology, Brisbane (QLD), Australia E-mail: fabio.zomervolpato@unitn.it / zomer.volpato@qut.edu.au ABSTRACT. In this work we present the design and development of a bioreactor for in vitro electrical stimulation, which delivers direct or alternated electrical potential difference (ΔV) to seeded scaffolds. This manuscript presents the technical considerations regarding the development of the device and its potential in tissue engineering, more specifically for neural stimulation. The equipment was built using National Instruments (NI) CompactRIO hardware. Technical specifications of the hardware include a real-time controller, compactRIO 9075 chassis, alternated/continuous output voltage supply (+-10 V and max 1 mA per channel) and current input for experiment feedback. Culture chambers where produced from polycarbonate with gold electrodes. The controlling software was designed in NI Labview environment, which allows users to control the delivery of the voltage to four independent channels and can stimulate the culture chambers independently and simultaneously. Electrical stimulation through functional electrical stimulators (FES) or bioreactors is a fairly simple, flexible and realistic technique to translate the bioelectricity present in the human body to in vitro and in vivo two- or three-dimensional cell cultures. Keywords: Tissue Engineering, Bioreactor, Electrical Stimulation, Neural Cells Stimulation 1. INTRODUCTION Tissue Engineering (TE) is a multidisciplinary field that unifies cell and molecular biology, materials science, and medical procedures. It aims to tackle the problem of tissue and organ regeneration and replacement. Tissue regeneration strategies can be either conducted entirely in vivo or assisted by an in vitro phase, which may provide more stable environment for cell survival. Commonly static cultures are used during the in vitro phase. Nevertheless, with advances in tissue engineering in the past decade, scientists have started to apply dynamic conditions through the use of bioreactors for in vitro cultures. A bioreactor can be defined as ‘any apparatus that attempts to mimic physiological conditions in order to maintain and encourage tissue regeneration in three-dimensional scaffolds’. Tissue Engineering has been exploring biomimetic approaches in order to enhance tissue formation and healing. Mimicking the physiological conditions can enhance and guide cell adhesion, proliferation and differentiation, increase extracellular matrix synthesis and growth factors secretion [1-3]. Specific bioreactors designs have been developed to improve structure and function of engineered tissues, such as: applying mechanical stimulus for bone and cartilage tissue [4, 5], electrical stimulus for neural and muscular tissues [6, 7], pulsatile-flow stimulus for heart tissue [8, 9] and perfusion for liver tissue [10, 11]. Several works have shown the benefits of the application of electrical stimuli to cardiomyocytes [12, 13], spiral ganglion neuron [3] and cochlear neurons [14] cultures. This manuscript presents the design and development of a bioreactor for in vitro electrical stimulation, which can deliver direct or alternated electrical potential difference (ΔV) to seeded scaffolds. The design was tuned to neural stimulation; nevertheless, the versatile platform in which it has been built allows users to simply modify and deliver a variety of signals. Here, we present the technical considerations regarding the development of the device. 2. DESIGN AND DEVELOPMENT 2.1 Hardware design The equipment was designed on a real-time embedded controller National Instruments (NI) CompactRIO (cRIO-9075) (Figure 1A) platform. The real-time embedded controller cRIO-9075 was connected to a NI cRIO-9075 chassis, containing an FPGA (Field Programmable Gate Array) Spartan-6 of 3 Mgate reconfigurable I / O with a clock frequency of 40 MHz. The cRIO system is a versatile platform that allows users to deliver and acquire a variety of signals, in parallel, through its embedded FPGA. The user is able to modulate the input and output signals, as required by each application, simply interchanging the I/O modules (Figure 1B-D) that are placed in the cRIO chassis. The developed bioreactor with its culture chambers and support is presented in Figure 2. The device was designed to stimuli four independent set of samples working in parallel. Each set of samples can contain up to 4 scaffolds, as seen in Figure 2, to arrive to a total of 16 samples being stimulated contemporaneously. Two current input modules give the current feedback of each scaffold during the experiments. The input channels were designed to allow 8 samples to work at high frequencies and 8 to work at lower frequencies but with a high sensitivity of the input signal. The culture chambers and its support were designed and manufactured in polycarbonate. Gold electrodes were used in the chambers. Such materials allow the sterilization of the chambers via autoclave. A summary of the hardware specifications is presented in Table 1. Figure 1: National Instruments (NI) CompactRIO, [A] cRIO 9075 chassis, [B] output N9263 module, [C] and [D] input modules N9203 and N9208, respectively. Table 1: Hardware specifications for the developed bioreactor. Output voltage ± 10 V Output current per channel max 1 mA Number of output channels 4 analog Digital-to-analog converter resolution Input current per channel 16 bits max ± 20 mA max ± 22 mA Number of input channels 8 16 Samples rate 200 kS/s 500 S/s Analog-to-digital converter resolution Type of stimulation Max stimulation frequency 16 bits 24 bits Continuous or alternated (square, triangular or sinusoidal waves) 2 kHz 5 Hz Figure 2: Designed bioreactor system depicting the controlling box, the culture chambers’ support and few chambers. 2.2 Software design The controlling software was programmed in NI Labview 11.0 environment. The software architecture is expanded over three main levels. The FPGA programming, where all I/O signals are generated, acquired and analyzed from the controller to the stimulation component. Signals are generated at high frequency (400 MHz), while it acquires and amplifies the measurements. The FPGA works in a deterministic way which allows simultaneous operations. Thus, the software permits the user to run parallel operations. An overview of the FPGA program can be seen in Figure 3. Figure 3: Block diagram of the FPGA program. The real-time microprocessor and the FPGA are synchronized in a deterministic way by the second programming level, which is permanently downloaded in the controller. This allows the autonomous control of the stimulation chambers, providing a high reliability, the possibility to manage all the working parameters and finally enabling the operator access to the front panel, directly or remotely via internet network. The measured data are then published on the local network via TCP/IP protocol. An overview of the real-time program can be seen in Figure 4. Figure 4: Block diagram of the real-time program. The third programming level is a user-friendly graphical interface. Such interface is not downloaded in the controller, instead it resides in the operator’s computer. This client interface downloads the data from the real-time via TCP/IP protocol. The control panel allows the user to set the desired parameters for the experiments, such as type of stimulus (continuous or alternated), type of wave (triangular, sinusoidal or square), periods of stimulation and rest, and the data to be saved. The data is saved in a .txt ASCII file and stored in the controller FTP file. The user panel can be seen in Figure 5. Figure 5: User interface control panel. 2.3 Stimulation description The applicable electrical potential difference can range from ±0.001 to ±10 V in continuous mode or with square, triangular or sinusoidal ramps at frequencies ranging from 0.001 Hz to 2 kHz. A number of stimulation profiles can be imposed to each independent channel by modifying the applied voltage and offset, frequency of stimulation, wave type, number of stimulations per day, duration of each stimulation and resting time between consecutive stimulations, as seen in Figure 6. Figure 6: Example of a stimulation profile. The system was developed to work inside a standard humidified incubator at 37 °C and 5% CO2. Once the scaffolds are positioned in the culture chambers, the single chambers can be fixed at the support and placed in the incubator. 3. FINAL REMARKS Bioelectric potentials are generated by a number of different biological processes, and are used by cells to govern metabolism, to conduct impulses along nerve fibres, and to regulate muscular contraction. It results from the conversion of chemical energy into electrical energy. Human bioelectricity is mostly present the nervous system signalling, muscular contraction and wound healing. The presented work is part of a project that aims to apply the latest advances in Tissue Engineering to enhance the repair outcome after spinal cord injuries. Nevertheless, the applicability of such system in different areas of TE has a high potential. The developed bioreactor was built in a versatile platform which allows the adaptation to different scaffold systems as well as additional output signals such as current. ACKNOWNLEDGEMENTS The research leading to these results has received funding from the European Union, Seventh Framework Programme [FP7/2007-2013] under grant agreement [Marie Curie FP7 – PCOFUND-GA-2008-226070, acronym “progetto Trentino”]. The authors also acknowledge BIOTOOLS s.l.r. for the cooperation on the development of the bioreactor. REFERENCES 1. Ding, Y., et al., Electro-acupuncture promotes survival, differentiation of the bone marrow mesenchymal stem cells as well as functional recovery in the spinal cord-transected rats. BMC neuroscience, 2009. 10. 2. Kotwal, A. and C.E. Schmidt, Electrical stimulation alters protein adsorption and nerve cell interactions with electrically conducting biomaterials. Biomaterials, 2001. 22(10): p. 1055-1064. 3. Thompson, B.C., et al., Effect of the dopant anion in polypyrrole on nerve growth and release of a neurotrophic protein. Biomaterials, 2011. 32(15): p. 3822-3831. 4. Martin, I., D. Wendt, and M. Heberer, The role of bioreactors in tissue engineering. Trends in Biotechnology, 2004. 22(2): p. 80-86. 5. Butler, D.L., S.A. Goldstein, and F. Guilak, Functional tissue engineering: The role of biomechanics. Journal of Biomechanical Engineering-Transactions of the Asme, 2000. 122(6): p. 570-575. 6. Becker, D., et al., Functional electrical stimulation helps replenish progenitor cells in the injured spinal cord of adult rats. Experimental neurology, 2010. 222(2): p. 211-218. 7. Green, R.A., et al., Conducting polymers for neural interfaces: Challenges in developing an effective long-term implant. Biomaterials, 2008. 29(24-25): p. 3393-3399. 8. Busse, R. and I. Fleming, Pulsatile stretch and shear stress: Physical stimuli determining the production of endothelium-derived relaxing factors. Journal of Vascular Research, 1998. 35(2): p. 73-84. 9. Hahn, M.S., et al., Physiologic pulsatile flow bioreactor conditioning of poly(ethylene glycol)-based tissue engineered vascular grafts. Annals of biomedical engineering, 2007. 35(2): p. 190-200. 10.Pazzano, D., et al., Comparison of chondrogensis in static and perfused bioreactor culture. Biotechnology progress, 2000. 16(5): p. 893-896. 11.Watanabe, S., et al., Hydrostatic pressure/perfusion culture system designed and validated for engineering tissue. Journal of Bioscience and Bioengineering, 2005. 100(1): p. 105-111. 12.Tandon, N., et al., Surface-patterned electrode bioreactor for electrical stimulation. Lab on a Chip, 2010. 10(6): p. 692-700. 13.Radisic, M., et al., Functional assembly of engineered myocardium by electrical stimulation of cardiac myocytes cultured on scaffolds. Proceedings of the National Academy of Sciences of the United States of America, 2004. 101(52): p. 18129-18134. 14.Thompson, B.C., et al., Conducting polymers, dual neurotrophins and pulsed electrical stimulation-dramatic effects on neurite outgrowth. Journal of controlled release : official journal of the Controlled Release Society, 2010. 141(2): p. 161-7.