English manual (From a translation of the original file - 5axes

advertisement

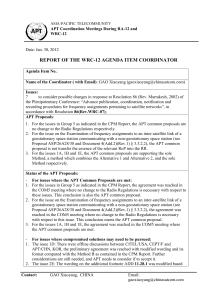

Winpost Version 0.4.6 October 11 e-mail: Usinage5axes@free.fr http://5axes.free.fr/devel_WinPost_en.htm Chapter 1 I SOFTWAREWinpost GENERAL INFORMATION. The majority of the CFAO create neutral files including of the instructions CN credits for the machines. Much is in called binary code Cl-dated, or in an adapted ASCII format of language APT. Certain FAO provide a high degree of flexibility, allowing to include a little all in the neutral file, whereas others are more restrictive. This utility makes it possible to convert these files APT for milling machines 3/4 axes and CU 3 or 5 axes. Generation of the code EMULATION OF CONTROLLERS CNC & SUPPORT CODES-G Winpost generates the codes G, supports the conditional checks of execution of the functions (other functions in the block course, values of current variables, states machine etc) which can change l' interpretation of the mot. Winpost integrates the majority of the functions like: The management the lengths d' tools Programming in point pivot (RTCP) Fixed cycles and shifts of origins The management of variables, under programs and macros as well as the loops and logical connections.To have the code list APT supported by the software defer to the chapter V “DEFINITION OF the CODES” LIMIT OF GUARANTEE Because many parameters external with the software can generate errors and collisions on the machine, no guarantee n' is provided, as for the exactitude of the course of the programs generated by the software. You must always keep in mind that this program is only one invaluable help for the development of your courses but will never provide a total safety of unfolding real of the courses. The program could not be held for person in charge of all damage direct, indirect, secondary or additional (financial losses due to the shortfall, with l' interruption d' activities or with the loss of data, etc, rising from l' use of the Program or l' d' impossibility; to use this one).I-1 Chapter 1 SYMBOLS USE IN THIS HANDBOOK This symbol appears beside specific notes notes explaining the particular functions current subject. This symbol appears beside the easy ways which return easier work to you. This symbol appears beside the warnings with the actions which could cause a damage with your work. I-2 Chapter 2 II USE OF THE SOFTWARE The principal interface of the software arises in the following form. With 5 distinct zones: Bar menus and icons Treated file APT ISO file obtained Tree of Posting of information Zone of information You can redimensionner the size of these zones while clicking on the bars of separation of these zones and by bringing these last on the desired position. In order to return these bars more visible following pictograms one added on the bars allowing of redimensionnerzones.pour the horizontal bar of redimensioning for the vertical bar of redimensioning. II-3 Chapter 2 TO CHARGE A POST-PROCESSOR To charge a post-processor you can use small Sélection Post-processor. Select then file PC (Post-processor Configuration) correspondent with vote machine. TO CHARGE A FILE APT The loading of files APT can be done either by the menu Ouvrir file APT or by the bar of icons. To open a file APT TO CONVERT FILE APT INTO ISO FILE The button launches the transformation starting from the zone of text. This button makes it possible to convert the file directly without run of the treatment of the code to the screen. In mode of direct transformation the processing times are much shorter . that mode from the zone of text You can also press on the key Echap (ESC) to stop the treatment. The treatment does not stop immediately but goes until the end of the instruction in progress. II-4 Chapter 2 Tree of information After having used the orders of transformation one finds in the tree of information a summary of the tools met in files APT. Many tools detected in file APT List detected tools Stagnation point While clicking with the button of right-hand side on a line this makes it possible to insert or remove one stagnation point. In mode of transformation from the zone of text will stop on the stagnation point requested. the transformation To insert a stagnation point: Click with the button of right-hand side of the mouse on line having to be used as stagnation point. Click with the button of right-hand side to insert the point. Re-click with the same button if you wish to remove. The use of the stagnation point is primarily used in the cases of development of the post-processor… II-5 Chapter 3 III DESCRIPTION OF THE FUNCTIONS FILE This menu gathers the functions making it possible to charge or safeguard the various types of file managed by the software. To open file APT Allows to give the responsability a file APT to be treated. To save ISO File Allows to record the Iso file obtained under the same name or another name. Selection post-processor Allows to select the configuration of the post-processor used. The configuration is stored in files (*.PPC) To open ISO File D' allows; to open an ISO file already postprocessé. To leave Closing of the file and exit of the program. TREATMENT Together functions of conversion of the ISO file. To convert from zone of text The Convertir function from zone of text makes it possible to launch the conversion of file APT starting from the zone of text. To convert directly This menu makes it possible to convert file APT directly. The end result will be charged in the zone with text located on the right of the software. This method is faster than the preceding one. III-6 Chapter 3 OPTIONS This group of menu gathers the optional functions making it possible to regulate certain parameters. One also finds in this group the functions to modify the configuration of a post-processor. Post-processor definition This function makes it possible to open the window of configuration of the post-processor. This function is also accessible by the button bar of tools. Option This menu allows d' to reach the general options of the WinPost program. It is thus possible to choose the language of the software thus qu' an option which makes it possible during the treatment of file since the line of order to close the program after the treatment of file APT. L' use of the program is then completely transparent for l' user. Exporter Log The function allows d' to export under a format text the messages present in the window d' posting of the messages. This function is especially useful for the debugging of the software and l' sending of d' report/ratio; use. RAZ Log Erase the zone of report/ratio. BY THE WAY Find in this menu the relative informations with the version of the current software. Version The Version function gives you the version of the software. This information is important in particular if you detected a problem in the software your information feedback must be obligatorily accompanied by the number of version. III-7 Chapter 3 III-8 Chapter 3 BAR TOOLS To open File APT Allows to open a file APT To save Iso Allows to save the ISO file after modifications. Configuration This button gives access to the configuration of the current post-processor. Conversion from zone of text Direct conversion Activate the conversion of the file from the zone of text. Carry out conversion directly since the textual file (faster but does not allow to follow the course of conversion). III-9 Chapter 4 IV TO CONFIGURE NEW POSTPROCESSORPRINCIPE The definition of the parameters is divided into 10 groups. Each group treating an aspect of the configuration of the post processor. The transformation into ISO of a file APT is only the writing under another format of the basic format. For this reason the program is there to only interpret what already exists in file APT. In particular the order of execution of the various parts and order is strongly related to the order of the instructions in file APT of origin. It is possible to differ the exit from an order but it will be difficult to leave information whereas the latter Na yet be defined in the APT origin. Format of a variable The fields defining a formatting of the addresses make it possible to define the code associated with the variable as well as the format with the associated numerical value. Exemple : X#0.000 For a value of 973.38814 X#0.000 turn overX973.388 X+#0.00 turn overX+973.39 (the sign is forced) IV-10 Chapter 5 The software uses the function in-house FORMAT to format the exit of the codes. It code being directly related to the regional parameters of your computer the exit of the point as separating decimal must thus be defines in the regional parameters of Windows. List Variables available In the zones of text defining a whole of line of code, it is possible to parameterize the exit of certain variables by including a code in the form: & (NOM_VARIABLE, FORMAT_DE_SORTIE) Example: N& (PP_N_LIGNE, #0) & (PP_SPINDLE, #) for the instruction stop pin will leave the code N120 M05 during the treatment of code APT SPINDL/OFF Existing variables PP_TOOL PP_S_SPINDLE PP_FEEDRATE PP_COOLNT PP_AIR : Number of the current tool : Value spindle speed : Value speed in advance current : Code M of current lubrication : Code M d' aspiration current PP_SPINDLE PP_COMMENT : Code M of startup of the pin current : Comment running coming is code TPRINT or of the last line $$ : Code G of correction current tool : Code for temporization PP_CORR PP_TEMPO PP_PARTNO PP_REWIND : Variable corresponding to code PARTNO of code APT : Variable corresponding to code PARTNO of code APT PP_FILE PP_NCFILE : Name of current the ISO File without the extension : Name of current the ISO File with the extension IV-1 Chapter PP_DATE PP_TIME 5 : Current date : Current hour These two variables are used to give the date and l' hour of creation of the ISO file Line example of parameter : N&(PP_N_LINE,0) ( Date : &(PP_DATE,DD/MM/YYYY) / &(PP_TIME,HH:MM) ) Result : N8 ( Date : 20/03/2011 / 14:29 ) PP_N_LINE : Number of the current line PP_FIRST_X PP_FIRST_Y PP_FIRST_Z PP_FIRST_A PP_FIRST_B PP_FIRST_C : Coordinates X of the first point after a change of tool : Coordinates Y of the first point after a change of tool : Coordinates Z of the first point after a change of tool : Coordinates has first point after a change of tool : Coordinates B of the first point after a change of tool : Coordinates C of the first point after a change of tool the automatic classification of the lines is not added with the codes not treated in the zones of text. You must thus add the N& code; (PP_N_LIGNE, #0) in front of the lines to be numbered. Existing variables for the cycles of drilling You will find hereafter the list of the variables available in the cycles of drilling. PP_TOOL PP_S_SPINDLE PP_FEEDRATE PP_COOLNT PP_AIR PP_SPINDLE PP_COMMENT : Number d' tool : Spindle speed : Speed d' advances : Code lubrication : Code aspiration : Direction of rotation of the pin: Comment First point to use for gone up after last drilling PP_FIRST_X: Coordinates X of the first point after a change of tool PP_FIRST_Y: Coordinates Y of the first point after a change of tool PP_FIRST_Z: Coordinates Z of the first point after a change of tool Variable Cycle PP_CYCLE_DEPTH: Current depth PP_CYCLE_FEED: Speed of the cycle PP_CYCLE_DWELL: Tempo current PP_CYCLE_RETRACT: value of the current distance from withdrawal PP_CYCLE_CLEARENCE: value of the current security distance PP_CYCLE_ZSTEP: Depth d' increment of drilling for cycles DEEP or BRKCHP current PP_CYCLE_PITCH: Step value for l' machining helicoid current PP_CYCLE_RADIALPASS: Radial master key for l' machining current spiral IV-2 Chapter 5 Premier Point PP_CYCLE_FIRST_X: Coordinates X of the first point of fixed cycle PP_CYCLE_FIRST_Y: Coordinates Y of the first point of fixed cycle PP_CYCLE_FIRST_Z: Coordinates Z of the first point of the fixed cycle Point de cycle PP_CYCLE_X PP_CYCLE_Y PP_CYCLE_Z : Coordinates X d' call d' a fixed cycle : Coordinates Y d' call d' a fixed cycle : Coordinates Z d' call d' a fixed cycle PP_CYCLE_A PP_CYCLE_B PP_CYCLE_C : Value angle has d' call d' a fixed cycle : Value angle B d' call d' a fixed cycle : Value angle C d' call d' a fixed cycle Variables for comment tool These variables are not available qu' with code APT CUTTER TOOL_NAME: Name of l' tool TOOL_NUM: Number of l' tool TOOL_DIAM: Diameter of l' tool TOOL_ANGLE: Angle of l' tool (conical tool) TOOL_RC: Ray of corner of l' tool TOOL_LG: Length of l' tool TOOL_LG_CUT: Cutting length of l' tool TOOL_LG_PROG: Length of l' programmed tool TOOL_REMARK : Comment associated with l' tool IV-3 Chapter 5 GENERAL General parameters of the post-processor Name: Name of the Post-processor. This information is used to name the post-processor. This name will be posted in the bar d' heading of the program. Type Post-processor: Siemens 840D Heidenhain ISO Conversational Heidenhain NUM FIDIA FANUC ROBOT KUKA Siemens 810T The type of the post-processor is an indication and can have an influence on the generated code or the way in which the program treats the code. Thus the configurations Conversational Heidenhain and Siemens 810 T are they specific. Repertory d' origin of files APT: localization of files APT. Allows to preferably specify a repertory for the loading of files APT Repertory of destination of the ISO files: localization d' writing of the ISO files Extension ISO File: Extension of generated the Iso files ex (.mpf for Siemens file or .h for conversational Heidenhain files) IV-4 Chapter 5 Exit comments: the comments present in file APT will be treated left in the ISO file. This corresponds to the code of the type $$ l' instruction PPRINT being treated as a specific instruction which can be a comment or a computer code. Comment beginning: Character indicating the d' beginning; a comment (example the point comma or the bracket) Fine comment: Character indicating the end d' a comment in a file Iso (example the bracket) Space inter code: A space is used to separate the codes. This lrend the more readable code but also larger. Exit number of line: Exit of the classification of the lines Exit number of line for comment: This option makes it possible to specify that the lines not comprising that comments will be also numbered To compress code: Allows to remove the codes nonmodal in order to limit the size of generated the Iso files. Ex :lines APT : GOTO / -45.89034, -44.44933, 0.000, 0.000, 0.000, 1.000 FEDRAT/ 1000.0000,MMPM GOTO / -45.89034, -44.44933, 16.10030, 0.000, 0.000, 1.000 Will give: G0 X-45.890 Z0.000 G1 X-45.8903 Y-44.4493 Z16.1003 A0.000 C0.000 F1000 if l' option n' is not activated and G0 X-45.890 Z0.000 G1 Z16.1003 F1000 Si l'option est activée Format number of line: Format for the exit of the numbers of line example: N#0 for an exit of the code of the type N10, N20 for a fixed exit: N0006 to use for example N#0000 To compress code: Allows to remove the codes non modal in order to limit the size of generated the Iso files. Starting number: Starting number for the numbers of line Increment of classification: Increment of classification example 5 for lines of 5 in 5 Number of maximum line: Maximum number of line. Once reached classification sets out again with the starting number. Tolerance calculation: Tolerance of calculation for function d' posting of the course or certain approximations. Value not used in current version of the post-processor. IV-5 Chapter 5 AXES Definition of the addresses for the axes machines Format des différents axes CN: X :Displacement on X Y :Displacement on Y Z :Displacement on Z I :Coordonnées I centre X pour les centres de cercle J :Coordonnées J centre Y pour les centres de cercle K :Coordonnées K centre Z pour les centres de cercle A :Format de l'axerotatif A B :Format de l'axerotatif B C :Format de l'axerotatif C R (Radius of circle): Format for the exit of the circular interpolations under the format R (by giving the ray of l' interpolation. Incremental coding: In the case or the notation incremental by a coding different from the linear axes (conversational Heidenhain example L IX IY IZ) l' passes; activation of this option makes it possible to add with the coding of axes X there Z the following code Macro code of return: Code to add with X Y and Z for a movement into incremental. IV-6 Chapter 5 Order of the axes: allows to specify l' order of exit of the Attention axes must contain the 13 following Letters: NGXYZ I J K R A B C F 1 2 3 4 5 6 7 8 9 10 11 12 13 L' order functions for the moment only for the exit of G XYZ and ABC IV-7 Chapter 5 STITCH & SPEED Definition of the codes and parameters governing the advances and startup of the pin. Stop Stitches: Code for l' stop of rotation of the pin (M05 Example) Stitch time direction: Code for the setting in rotation of the pin clockwise (M03 Example) Stitch anti-clockwise direction: Code for the setting in rotation of the pin anticlockwise (M04 Example) Code speed: Code of exit of the advances F#0 example for an exit of the type F1000 Pré codes speed: Code beginning of line for management speed Code speed stitches: Code for the rotation of the pin S#0 example for an exit of the S10000 type Startup stitches: Complete sequence for the startup of the pin Example for Heidenhain post-processor: & (PP_N_LIGNE, #0) TOOL CAL & (PP_TOOL, #0) Z S& (PP_S_SPINDLE, #0) & (PP_N_LIGNE, #0) & (PP_SPINDLE, #0)Donneune sortie du type : 8 TOOL CALL 1 Z S2000 9 M03 Stop stitches: Sequence of code supplements for l' stopping of the pin. Heidenhain example: &(PP_N_LIGNE,#0) L M05 IV-8 Chapter 5 Give :574 L M05 IV-9 Chapter 5 CODE G Définition des codes G. G01 Work advances: Definition of the code d' work advances G00 Advances fast: Definition of the code d' advances fast G70 work in INCH: Definition of work in INCH G71 work into metric: Definition of work into metric G90 work in absolute: Displacement mode in absolute G91 work of relative: Mode of displacement into relative (activated with codes APT GODLTA) G17 plan XY Definition of the standard schemes of work G18 plan ZY G19 plan YZ Tempo: D' definition; an instruction of temporization (code APT DELAY) Code for origin: definition of the code for an origin Code for shift origin: Allows with codes APT ORIGIN to define a news origin Code for treatment FROM: Code for treatment of code APT FROM Fast exit advances fast: rapid displacements can be left in advance work with a speed known as fast. This option makes it possible to replace the G00 code by a G1 code and a speed d' advances defined in the two following parameters. IV-10 Chapter 5 Code advances fast G1: Code displacement intended to replace G00 Speed advances fast: Speed used for displacements in rapid Time circular G02: Code circular displacement G02 Circulairetrigo G03: Code circular displacement G03 Format Left Circle: D' definition; a circular instruction of displacement Particular case of the exit of the circular interpolations As for the codes of beginning and end of file the exit of a circular interpolation is managed by a text which can contain variables. It is possible to parameterize the exit of certain variables by including a code in the form: & (NOM_VARIABLE, FORMAT_DE_SORTIE) Exemple : N&(PP_N_LINE,#0) &(PP_SPINDLE,#) for the instruction stop pin will leave it codeN120 M05 during the treatment of code APT SPINDL/OFF Existing variables PP_FEEDRATE PP_COMMENT : Value speed in advance current : Comment running coming is code TPRINT or of the last line $$ PP_CORR : Code G of correction current tool PP_CODE_RING : Code circular interpolation G02/G03 PP_CENTRE_RELATIF_X: Coordinates into relative compared to starting point X point of center PP_CENTRE_RELATIF_Y :Coordinates into relative compared to the starting point Y of the point of center PP_CENTRE_RELATIF_Z :Coordinates into relative compared to starting point Z of the point of center. PP_CENTRE_ABSOLU_X: Coordinates absolute X of the point of center. PP_CENTRE_ABSOLU_Y: Coordinates absolute Y of the point of center. PP_CENTRE_ABSOLU_Z: Coordinates absolute Z of the point of center. PP_POINT_CERCLE_X: Coordinates X of the point of end of definition of the interpolation circular PP_POINT_CERCLE_Y: Coordinates Y of the point of end of definition of the interpolation circular PP_POINT_CERCLE_Z: Coordinates Z of the point of end of definition of the interpolation circular PP_RAYON_CERCLE: Circle radius PP_ANGLE_CERCLE: Circle Angle IV-11 Chapter 5 PP_POINT_MID_CERCLE_X: Coordinates X of the middle point when using an interpolation circular by 3 points PP_POINT_MID_CERCLE_Y: Coordinates Y of the middle point when using an interpolation circular by 3 points PP_POINT_MID_CERCLE_Z: Coordinates Z of the middle point when using an interpolation circular by 3 points PP_ANGLE_A_CERCLE: Angle Machine has one end off interpolation PP_ANGLE_B_CERCLE: Angle Machine B one end off interpolation PP_ANGLE_C_CERCLE: Angle Machine C one end off interpolation CODE M Definition of the codes M and management of lubrication. In the codes M one will find the blocking of the rotary axes and the code of end d' operation or d' temporary stop operator. Exit Codes Lubrication: L' activation of l' option makes it possible to take into account codes APT COOLNT and to leave the corresponding code Lubrication ONE: Lubrification OFF: Lubrification FLOOD: Lubrification AIR: code corresponding to code APT COOLNT /ON code corresponding to code APT COOLNT /OFF code corresponding to code APT COOLNT /FLOOD code corresponding to code APT COOLNT /AIR Air ON: code corresponding to code APT AIR /ON Air OFF: code corresponding to code APT AIR /OFF Stop Operation: M01 Codes stop operation IV-12 Chapter 5 Stop Programs: M00: code stop programs M00 Blocking Centers ON: code blocking of the axes codes APT CLAMP/ON Blocking Centers OFF: code blocking of the axes codes APT CLAMP/OFF Blocking Axe a: codes blocking of the rotary axes has code APT CLAMP/AAXIS ONE and OFF Blocking Centers b: codes blocking of the rotary axes B codes APT CLAMP/BAXIS ONE and OFF Blocking Centers C: code blocking of the rotary axes C codes APT CLAMP/CAXIS ONE and OFF Code AUXFUN: Definition of the exit of code AUXFUN. Code AUXFUN makes it possible to specify a digital code generally used with a code Mr. IV-13 Chapter 5 TOOL Definition of the codes of management of the tools Corrector cancellation: Code d' cancellation of corrector d' tool Left corrector: Code d' activation of the correction d' tool on the left of the Correct profile right-hand side: Code d' activation of the correction on the right of the profile Corrector at the end of the line: Place the code of correction at the end of the line. Example codes for heidenhain: 216 L Y3.028 Z2.786 RL Management codes TOOLNO: This option makes it possible to take into account code TOOLNO the following sequence makes it possible to define the code used to manage code TOOLNO TOOL cancellation: Together of code to cancel the loading tool before passing to the following loading. Heidenhain example: TOOL CAL 0 Change TOOL: Code change d' a tool Example of configuration: ConfigWinPost T& (PP_TOOL, #0) D& (PP_TOOL, #0) G54 IV-14 Chapter 5 Exit Machine T6D6 G54 Exit codes CUTTER: This option allows d' to use information coming from code APT CUTTER to leave either the comment or the instructions The following sequence makes it possible to define the code used to manage code CUTTER. Note: These instructions use specific variables which are described in the Liste paragraph Variables available page IV-1. Example of code ConfigWinPost: (TOOL DIAMETER &(TOOL_DIAM,#0)/ RAD CORNER &(TOOL_RC,#0)) Will give in the code Iso Sortie Machine: (TOOL DIAMETER 20 / RAD CORNER 5) IV-15 Chapter 5 5AXES Definition of the kinematics of the machine 5axes as well as its limits on the axes. Type: Inform the type of machine to be simulated. In the currently available type one will find: Type 1 = Type 2 = Type 3 = Type 4 = Type 5 = Type 6 = Type 7 = Type 8 = Type 9 = Type 10 = Type 11 = Type 12 = Type 13 = Type 14 = Type 15 = Type 16 = Type 17 = Type 18 = 3 Axes Head A/B Head A/C Head B/C Head A/C 45° Head B/C 45° A/C Plate B/C Plate A/C Plate 45° B/C Plate 45° Tête A/C Plate Tête B/C Plate Tête 45° A/C Standard Tête Standard 45° B/C Plateau HEULER A/B/C Kuka A/B/C Multifunction Standard Turning Notation IJK (A3B3C3) Controlled types of axis IV-16 Chapter Type Linear Translation Rotation RollOver Rotation Modulo 5 Description Part controlled in rotation. Rotation in linear mode Part controlled in translation Part controlled in rotation. Rotation in mode RollOver Part controlled in rotation. Rotation in mode Modulo 360° Mini limit A/B: Limit of l' center has or B minimum Limite A/B Maxi: Limit of l' center has or B maximum Mini limit C: Limit of l' center C minimum Limite C Maximum: Limit of l' center C maximum Activation RTCP: Code for l' activation of management RTCP (code APT MULTAX ONE) Desactivation RTCP: Code for l' activation of management RTCP (code APT MULTAX OFF) Activation Tilted Plan: Code for l' activation d' a tilted plan Desactivation Tilted plan: Code for desactivation d' a tilted plan IV-17 Chapter 5 FIXED CYCLES Definition of the fixed cycles of drilling, tapping, facing, boring… Code drilling: definition of the code fixes for the operations of drilling. Code chamfering: definition of the code fixes for the operations of chamfering. Code facing: definition of the code fixes for the operations of facing. Code deep drilling: definition of the code fixes for the operations of deep drilling Code breaks chips: definition of the fixed code for the operations of drilling breaks chips. Code boring: definition of the code fixes for the operations d' boring. Code tapping: definition of the code fixes for the operations of tapping. Code threading: definition of the code fixes for the operations of threading. Code machining helicoid: definition of the code fixes for the operations of drilling helicoid. Fast displacement after fixed cycle: Code to define a withdrawal in rapid after a fixed cycle. Code stop of the cycle: Code to define the end d' fixed activation of cycle. Example: G80 Call not of cycle: Code allowing to define the points d' call ' a fixed cycle. IV-18 Chapter 5 DEBUT/FIN FILE Definition of the beginnings and end of file. End of line: Code added at the end of the ISO lines Example: * Beginning to card-index: Together codes for the beginning of the ISO files End of file: Together codes for the end of the ISO files Management PARTNO: Code for the management of code PARTNO. Management codes finished: Code corresponding to FINISHED code APT Management codes end: Code corresponding to code APT END Management REWIND: Code corresponding to code APT REWIND IV-19 Chapter 5 COLOR Definition of the colors for the analysis of code APT. Color text Definition of the colors for the description of syntax in code APT. To modify a double color click on the text or the box color and select the desired color. The red color is prohibited, it is reserved for the marking of the lines having generated errors. COLOR_COMMENT: COLOR_INCONNUE: COlOR_PARTNO: COLOR_RAPID: COLOR_COOLNT: COLOR _TPRINT: COLOR _CUTCOM: COLOR _TLAXIS: COLOR _SPINDL: COLOR _FEDRAT: COLOR _GOTO: COLOR _REWIND: COLOR _TOOLNO: COLOR _LOADTL: COLOR _END: COLOR _FINI: COLOR _CYCLE: IV-20 Chapter 5 COULEUR_CIRCLE : COULEUR_CUTTER : COULEUR_UNITS : COULEUR_MCS : COULEUR_MULTAX : COULEUR_SELECT : COULEUR_FROM : COULEUR_PPFUN : COULEUR_PPRINT : COULEUR_INSERT : COULEUR_LOAD : COULEUR_DISPLY : COULEUR_OPSTOP : COULEUR_STOP : COULEUR_DELAY : COULEUR_PREMIER_POINT : COULEUR_ORIGIN : COULEUR_INDIRV : COULEUR_TLON_GOFWD : COULEUR_AIR : COULEUR_CAMP : COULEUR_AUXFUN : COULEUR_GODLTA : COULEUR_PREFUN : COULEUR_GOHOME : COULEUR_MODE : IV-21 Chapter 5 PARTICULAR INSTRUCTIONS Definition of the particular instructions. First Point after change tool: These codes make it possible to define the plays d' instructions of the first item discussed after a change d' tool. Macro of STRONG CURRENT of the rotary axes: In the case or l' rotary axis of the machine reached a limit it is then necessary to give to Zero the axes. Or to rock with 180° on an axis. This plays of code then makes it possible to define this restoring of the codes. Code for macro return at the origins: Macro to manage the codes of return at the origins. Corresponds to the treatment of code APT GOHOME. Attention in this case l' writing of the codes uses aa little special notation example: Example ISO :N&(PP_N_LINE,0) G91 G28 &(0.000,X~) &(0.000,Y~) &(0.000,Z~) The notation X~, Y~ and Z~ makes it possible to specify the value of return the code of l' center n' having left that if l' axis is specified in code APT.Idem pour la vitesse F~ IV-22 Chapter 5 Example : for the notation : N&(PP_N_LINE,0) G91 G28&(0.000,X~)&(0.000,Y~)&(0.000,Z~) GOHOME/ZAXIS will give N3 G91 G28 Z0.000 CasHeidenhain :&(PP_N_LINE,#0) &("M140 MB MAX",Z~) Donnera pour le même code APT M140 MB MAX To note qu' there exists also the notation F! In this case if the F n' then one is not present uses the code of substitution for speed: Example of coding with the two notations :&(F#0,F~)&("FMAX",F!) If F is present one will have then Fla value of l' advances if not FMAX at the end of the file Management of code APT Mode: Allows to define the codes associated with code APT Mode. definition is particular because it is necessary here to define on a line the treatment associated with a code MODE. The codes MODE can be also varied is it difficult of all to validate them one has for example MODE/ INCHES MM XYPLAN YZPLAN ZXPLAN ABSOL INCR MILL … Example to define the management of the code MODE: INCHES/N&(PP_N_LIGNE,0) G20 MM/N&(PP_N_LIGNE,0) G21 Thus MODE/INCHES will give N3 G20 IV-23 Chapter 6 V DEFINITION OF CODES APT SUMMARY OF FUNCTIONS APT In red codes untreated in the software in the current version of the software. CODES APT DRAFTS Code list APT recognized by l' application. FEDRAT: definition speeds d' advances. Example of code: FEDRAT/1000.0000, MMPM CUTTER: d' definition; a geometry d' tool. Example of code: CUTTER/20.000,4.000,6.000,4.000,0.000,0.000,50.000 SPINDL: definition spindle speeds. Example of code: SPINDL/70.0000, RPM, CLW following possibility: SPINDL/OFF CUTCOM: Activation of the codes of correction of ray. Example of code: CUTCOM/OFF TLAXIS: definition of L' orientation of l' center tool. Example of code: TLAXIS/0.000,0.000,1.000 COOLNT: instructions of ordering of lubrication. Example of code: COOLNT/ON LOADTL :chargement d'un outil . Exemple de code : LOADTL/3 TOOLNO: definition number d' tool. Example of code: TOOLNO/1, 10.000 PPRINT: Exit comment tool. Example of code: PPRINT/T1 Mills 2 Sizes D 10 GOTO: instructions of displacement. Example of code: GOTO/95.36711,59.09059,27.12479 GODLTA: instructions of displacement into relative. Example of code: GODLTA/0.0000,0.0000,3.0000 RAPID: displacement in rapid. Example of code: RAPID In English V-24 FROM: Definition of the starting point Chapter 6 PREFUN: displacement in rapid. Example of code : RAPID CIRCLE & TLON,GOFWD: Circular interpolation Winpost decodes aujourd' today 3 notations for the circular instructions.. First notation CIRCLE gives the point of centre and the normal one as well as. This normal allows to specify the direction of course (G02 or G03 for example for Z=1 with a circle in the plan G17 (XY) one will have an interpolation trigo G03 and G02 if Z=-1 CIRCLE/X-center, there-center, Z-center, X-normal, there normal, normal Z, ray) GOTO/xPointFin, y-PointFin, Z PointFin Exemple : CIRCLE/508.000,762.000,0.000,0.000,0.000,1.000,137.000 GOTO/645.000,762.000,0.000 L' another notation recognized and used uses code TLON, GOFWD with the notation INDIRV which gives the direction of course to the first point of the circle. The vector thus defined makes it possible to know the direction of course G02/G03. INDIRV/X-value, there-value, Z-value TLON, GOFWD/(CIRCLE/X-center, there-center, Z-center, ray), ONE, (LINE/X-center, therecenter, Z-center, x-PointFin, there PointFin, Z PointFin) Exemple : INDIRV/ 0.99503, 0.09957, 0.000 TLON,GOFWD/ (CIRCLE/ 0.16933, 0.12173, 0.000,0.04177),ON,(LINE/ 0.16933, 0.12173, 0.000,0.20325, 0.14611, 0.000) Finally the same notation is also treated if codes CIRCLE and LINE are defined in their affecting a reference (Lx and Cx) which will be used in code TLON, GOFWD as in l' following example: C1=CIRCLE/41.6,-1.0681,14.7351,3 L1=LINE/41.6,-1.0681,14.7351,38.6,-1.0681,14.7351 INDIRV/-1,0,0 TLON,GOFWD/C1,ON,L1 V-25 Chapter 6 Attention the declaration of orders CIRCLE and LINE must be done before l' call by TLON, GOFWD. It n' is thus not possible to define at the beginning of code APT all references CICRLE & LINE. FROM :D' definition; a starting point REWIND :D' definition; an instruction of defect SELECT :Selection d' an origin (left the code of the G54 type for example). Exempleof code : SELECT/54 MODE :D' definition; an operating process. Exemple ofcode : MODE/ INCHES MM XYPLAN YZPLAN ZXPLAN ABSOL INCR ORIGIN :D' definition; an origin (either with call d' a code G FIXTUR (G54, G55. ) is with value of l' origin DATUM X, Y, Z Exemple de code : ORIGIN / FIXTUR, 2 ===> G55 ORIGIN / DATUM, 1.0, 2.5, 3.9 CLAMP :D' definition; year instruction off rblocage d' year axis Example of code: CLAMP / ON / OFF / AAXIS, ON / BAXIS, OFF GOHOME :Return at the origins. L' one can specify on which axes can be made return. Example of code: GOHOME / XAXIS, YAXIS, ZAXIS UNITS :Order definition of units G70/G71. Example of code : UNITS/MM PPFUN: Recognized but untreated function. MCS :Recognized but untreated function. AUXFUN :D' definition; an auxiliary function (partner with a code M) V-26 Chapter 6 PREFUN :D' definition; a preparatory function (partner with a code G) Codes for the fixed cycles CYCLE : CYCLE/DRILL : définition of cycle fixes . Example ofcode : CYCLE Percage, pointage .CYCLE/DRILL,30.4,6451.6,MMPM,2.54 CYCLE/TAP : taraudage .CYCLE/TAP,30.4,6451.6,MMPM,2.54 CYCLE/REAM : Alesage .CYCLE/REAM,30.4,6451.6,MMPM,2.54 CYCLE/MILL :percage par hélicoïdale .CYCLE/MILL,30.4,6451.6,MMPM,2.54 CYCLE/BORE : percage .CYCLE/BORE,30.4,6451.6,MMPM,2.54 CYCLE/FACE : surfacage .CYCLE/FACE,30.4,6451.6,MMPM,2.54,100 CYCLE/BORE,DWELL: percage avec temporisation .CYCLE/BORE,DWELL,30.4,6451.6,MMPM,2.54,100 CYCLE/CSINK : chamfreinage .CYCLE/CSINK,30.0,30.0,6451.6,MMPM,2.54 CYCLE/DEEPCL : percageprofond .CYCLE/DEEPCL,30.4,6451.6,MMPM,2.54,INCR,10.0,10.0 CYCLE/DEEPBK : cycle brisecopeaux .CYCLE/DEEPBK,30.4,6451.6,MMPM,2.54,INCR,10.0,10.0 CYCLE/OFF : instructions de fin de cycle .CYCLE/OFF Code CYCLE/OFF Exemples CYCLE/DEEPBK CYCLE/DEEPBK,30.4,6451.6,M MPM,2.54,INCR,10.0,10.0 CYCLE/OFF Description Paramètres Instructions of end of cycle. Cycle breaks chips V-27 Chapter 7 VI MODIFICATIONS OF THE VERSION Version 0.0.8 Date : 10/12/2006 TailleExécutable : 740 Ko (757 760 octets) Corrections Corrections on management Codes CIRCLE in G17 plan New functions Integration, of new codes management speed. Version 0.2.x Date : 10/11/2010 TailleExécutable : 708 Ko (724 992 octets) New functions Test of the version of files PC Version 0.2.x Date : 10/11/2010 TailleExécutable : 708 Ko (724 992 octets) New functions Management of the Heidenhain exits Version 0.2.18 & 0.2.19 Date : 9/02/2011 TailleExécutable : 760 Ko (778 240 octets) New functions Management of codes APT AUXFUN and CLAMP Addition option for exit corrector tool at the end of the line (heidenhain) Version 0.3.x Date : 10/02/2011 TailleExécutable : 760 Ko (778 240 octets) New functions Management of codes GODLTA with displacement in this case into relative (G91) Version 0.3.2 Date : 10/02/2011 TailleExécutable : 760 Ko (778 240 octets) New functions Management codes PREFUN Gestion of code GOHOME Corrections The exit of code TLAXIS generates an instruction of the plane type standard G17, G18… VI-28 Chapter 7 Version 0.3.3 Date : 17/03/2011 TailleExécutable : 772 Ko New functions Addition of variables PP_DATE and PP_TIME Version 0.3.4 Date : 27/04/2011 TailleExécutable : 784 Ko New functions Management of the code MODE Corrections Management of codes CYCLES SEED-PLANTING DRILL and DEEP according to example CATIA APT VERSION Version 0.4.0 Date : 28/04/2011 TailleExécutable : 784 Ko Corrections Modification on code GOHOME Version 0.4.1 à 0.4.5 Date : 28/05/2011 TailleExécutable : 784 Ko New functions Management of code TLON, GOFWD with notation of codes CIRCLE and LINE in reference. Corrections Correction of several minor problems of second reading and correction on treatment codes INDRIV for direction of the circle. Version 0.4.6 Date : 28/08/2011 TailleExécutable : 816 Ko New functions Possibility of defining order of exit of axes XYZ ABC and the code G Corrections On calculation B & C for standard machine 5 axes Gantry B& C VI-29 Chapter I 8 SOFTWARE WINPOST I-1 GENERAL INFORMATION. I-1 Emulation of controllers CNC & Support codes-G I-1 LIMIT OF GUARANTEE I-1 SYMBOLS USE IN THIS HANDBOOK I-2 II II-3 USE OF THE SOFTWARE To charge a POST-PROCESSOR II-4 To charge a file APT II-4 To convert file APT into File ISO Tree of information Stagnation point II-4 II-5 II-5 III III-6 DESCRIPTION OF THE FUNCTIONS File To open file APT To save ISO File Selection post-processor To open ISO File To leave III-6 III-6 III-6 III-6 III-6 III-6 TREATMENT To convert from zone text To convert directly III-6 III-6 III-6 Options Definition post-processor Option To export Log STRONG CURRENT Log III-7 III-7 III-7 III-7 III-7 By the way Version III-7 III-7 Bar tools III-9 IV TO CONFIGURE A NEW POST-PROCESSOR PRINCIPLE IV-10 IV-10 30 Chapter Format of a variable List Variables available 8 IV-10 IV-1 GENERAL IV-4 AXES IV-6 STITCH & SPEED IV-8 CODE G Particular case of the exit of the circular interpolations IV-10 IV-11 CODE M IV-12 TOOL IV-14 5AXES IV-16 CYCLES FIXES IV-18 DEBUT/FIN FILE IV-19 COLOR Color text IV-20 IV-20 PARTICULAR INSTRUCTIONS IV-22 V DEFINITION OF CODES APT V-24 SUMMARY OF FUNCTIONS APT V-24 Treated codes APT Codes for the fixed cycles V-24 V-27 VI MODIFICATIONS OF THE VERSION VI-28 31