Composites

advertisement

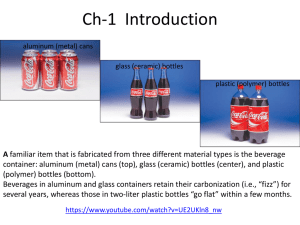

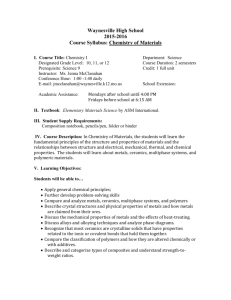

I chapter 1 General introduction General Material Classifications There are thousands of materials available for use in engineering applications. Most materials fall into one of three classes that are based on the atomic bonding forces of a particular material. These three classifications are metallic, ceramic and polymeric. Additionally, different materials can be combined to create a composite material. Within each of these classifications, materials are often further organized into groups based on their chemical composition or certain physical or mechanical properties. Composite materials are often grouped by the types of materials combined or the way the materials are arranged together. Below is a list of some of the commonly classification of materials within these four general groups of materials. Metals Ferrous metals and alloys (irons, carbon steels, alloy steels, stainless steels, tool and die steels) Nonferrous metals and alloys (aluminum, copper, magnesium, nickel, titanium, precious metals, refractory metals, superalloys) Ceramics Glasses Glass ceramics Graphite Diamond Polymeric Thermoplastics plastics Thermoset plastics Elastomers Composites Reinforced plastics Metal-matrix composites Ceramic-matrix composites Sandwich structures Concrete Each of these general groups will be discussed in more detail in the following pages. Second class /polymer dep./material physics II chapter 1 General introduction HOW CAN WE COMPARE MATERIALS? - Performance Physical - Chemical Properties - Composition & Structure -Processing & Synthesis These four categories are useful ways to sort different materials. Metals, polymers and ceramics tend to have great differences in these categories. PROPERTIES To choose a material with the best performance for a particular application, we will need to consider the properties of the available materials. Properties are the observed characteristics of a sample. Physical properties Some physical properties describe how an object responds to mechanical forces. Hardness is one example of a mechanical property. If you drag a steel knife blade across a hard object, such as a plate, the hard surface is unchanged; if you drag the blade across a soft object, such as a piece of chalk, the soft surface will be scratched. An object is tough if force is unable to break or tear it. The response to force depends on the material's structure, and also on its shape and size. A piece of notebook paper can be torn easily, but a telephone book requires much greater force. We can easily bend a flexible object such as a nylon jacket, but more force is required to bend a stiff object like a polyethylene milk jug. If an object returns to its original shape and size when the force is removed, we call it elastic. If the deformation remains, it is plastic. An object that breaks rather than bending is brittle. 1-5 An object is strong if an applied force is unable to deform or break it. A nylon Windbreaker is strong, since pulling on it does not change its length. Sometimes the manner of applying a force makes a difference to the strength of an object. Ceramics can bear a lot of weight, but will break if stretched or bent. Nylon survives compression, pulling and twisting. Second class /polymer dep./material physics III chapter 1 General introduction Color, texture, and reflectivity can be observed by shining light on a sample. Mirrors are colorless, smooth, and shiny. Electrical conductivity is detected by applying a voltage across an object. Applying heat to a sample reveals its ability to conduct heat, its melting point (temperature at which a solid changes to liquid), and its boiling point (temperature at which a liquid changes to gas). Some properties are independent of the amount of sample. Melting point does not change if a sample is divided in half. Other properties, including mass and volume, increase with the amount of sample being studied. When observing properties in a laboratory, scientists use the Metric System of measurements. The basic units of the Metric System are presented in Metals Metals account for about two thirds of all the elements and about 24% of the mass of the planet. Metals have useful properties including strength, ductility, high melting points, thermal and electrical conductivity, and toughness. From the periodic table, it can be seen that a large number of the elements are classified as being a metal. A few of the common metals and their typical uses are presented below. Common Metallic Materials Iron/Steel - Steel alloys are used for strength critical applications Aluminum - Aluminum and its alloys are used because they are easy to form, readily available, inexpensive, and recyclable. Copper - Copper and copper alloys have a number of properties that make them useful, including high electrical and thermal conductivity, high ductility, and good corrosion resistance. Titanium - Titanium alloys are used for strength in higher temperature (~1000° F) application, when component weight is a concern, or when good corrosion resistance is required Nickel - Nickel alloys are used for still higher temperatures (~1500-2000° F) applications or when good corrosion resistance is required. Refractory materials are used for the highest temperature (> 2000° F) applications. Second class /polymer dep./material physics IV chapter 1 General introduction The key feature that distinguishes metals from non-metals is their bonding. Metallic materials have free electrons that are free to move easily from one atom to the next. The existence of these free electrons has a number of profound consequences for the properties of metallic materials. For example, metallic materials tend to be good electrical conductors because the free electrons can move around within the metal so freely. More on the structure of metals will be discussed later. Ceramics A ceramic has traditionally been defined as “an inorganic, nonmetallic solid that is prepared from powdered materials, is fabricated into products through the application of heat, and displays such characteristic properties as hardness, strength, low electrical conductivity, and brittleness." The word ceramic comes the from Greek word "keramikos", which means "pottery." They are typically crystalline in nature and are compounds formed between metallic and nonmetallic elements such as aluminum and oxygen (alumina-Al2O3), calcium and oxygen (calcia - CaO), and silicon and nitrogen (silicon nitride-Si3N4). Depending on their method of formation, ceramics can be dense or lightweight. Typically, they will demonstrate excellent strength and hardness properties; however, they are often brittle in nature. Ceramics can also be formed to serve as electrically conductive materials or insulators. Some ceramics, like superconductors, also display magnetic properties. They are also more resistant to high temperatures and harsh Second class /polymer dep./material physics V chapter 1 General introduction environments than metals and polymers. Due to ceramic materials wide range of properties, they are used for a multitude of applications. The broad categories or segments that make up the ceramic industry can be classified as: Structural clay products (brick, sewer pipe, roofing and wall tile, flue linings, etc.) Whitewares (dinnerware, floor and wall tile, electrical porcelain, etc.) Refractories (brick and monolithic products used in metal, glass, cements, ceramics, energy conversion, petroleum, and chemicals industries) Glasses (flat glass (windows), container glass (bottles), pressed and blown glass (dinnerware), glass fibers (home insulation), and advanced/specialty glass (optical fibers)) Abrasives (natural (garnet, diamond, etc.) and synthetic (silicon carbide, diamond, fused alumina, etc.) abrasives are used for grinding, cutting, polishing, lapping, or pressure blasting of materials) Cements (for roads, bridges, buildings, dams, and etc.) Advanced ceramics o Structural (wear parts, bioceramics, cutting tools, and engine components) o Electrical (capacitors, insulators, substrates, integrated circuit packages, piezoelectrics, magnets and superconductors) o Coatings (engine components, cutting tools, and industrial wear parts) o Chemical and environmental (filters, membranes, catalysts, and catalyst supports) The atoms in ceramic materials are held together by a chemical bond which will be discussed a bit later. Briefly though, the two most common chemical bonds for ceramic materials are covalent and ionic. Covalent and ionic bonds are much stronger than in metallic bonds and, generally speaking, this is why ceramics are brittle and metals are ductile. Second class /polymer dep./material physics VI chapter 1 General introduction Polymers A polymeric solid can be thought of as a material that contains many chemically bonded parts or units which themselves are bonded together to form a solid. The word polymer literally means "many parts." Two industrially important polymeric materials are plastics and elastomers. Plastics are a large and varied group of synthetic materials which are processed by forming or molding into shape. Just as there are many types of metals such as aluminum and copper, there are many types of plastics, such as polyethylene and nylon. Elastomers or rubbers can be elastically deformed a large amount when a force is applied to them and can return to their original shape (or almost) when the force is released. Polymers have many properties that make them attractive to use in certain conditions. Many polymers: are less dense than metals or ceramics, resist atmospheric and other forms of corrosion, offer good compatibility with human tissue, or exhibit excellent resistance to the conduction of electrical current. The polymer plastics can be divided into two classes, thermoplastics and thermosetting plastics, depending on how they are structurally and chemically bonded. Thermoplastic polymers comprise the four most important commodity materials – polyethylene, polypropylene, polystyrene and polyvinyl chloride. There are also a number of specialized engineering polymers. The term ‘thermoplastic’ indicates that these materials melt on heating and may be processed by a variety of molding and extrusion techniques. Alternately, ‘thermosetting’ polymers can not be melted or remelted. Thermosetting polymers include alkyds, amino and phenolic resins, epoxies, polyurethanes, and unsaturated polyesters. Rubber is a natural occurring polymer. However, most polymers are created by engineering the combination of hydrogen and carbon atoms and the arrangement of the chains they form. The polymer molecule is a long chain of covalent-bonded atoms and secondary bonds then hold groups of polymer chains together to form the polymeric material. Polymers are primarily produced from petroleum or natural gas raw products but the use of organic substances is growing. The super-material known as Kevlar is a man-made polymer. Kevlar is used in bullet-proof vests, strong/lightweight frames, and underwater cables that are 20 times stronger than steel. Second class /polymer dep./material physics VII chapter 1 General introduction General properties of materials Characteristic Properties of Major Classes metals polymers -hard but malleable -shiny -little color -intermediate -conduct electricity -high density -difficult to burn ceramics stiff or flexible hard but brittle dull shiny if glazed colorless many colors low melting highest melting -point nonconductive non-conductive low density intermediate density flammable not flammable Composites A composite is commonly defined as a combination of two or more distinct materials, each of which retains its own distinctive properties, to create a new material with properties that cannot be achieved by any of the components acting alone. Using this definition, it can be determined that a wide range of engineering materials fall into this category. For example, concrete is a composite because it is a mixture of Portland cement and aggregate. Fiberglass sheet is a composite since it is made of glass fibers imbedded in a polymer. Composite materials are said to have two phases. The reinforcing phase is the fibers, sheets, or particles that are embedded in the matrix phase. The reinforcing material and the matrix material can be metal, ceramic, or polymer. Typically, reinforcing materials are strong with low densities while the matrix is usually a ductile, or tough, material. Some of the common classifications of composites are: Reinforced plastics Metal-matrix composites Ceramic-matrix composites Sandwich structures Concrete If the composite is designed and fabricated correctly, it combines the strength of the reinforcement with the toughness of the matrix to achieve Second class /polymer dep./material physics VIII chapter 1 General introduction a combination of desirable properties not available in any single conventional material. Some composites also offer the advantage of being tailor able so that properties, such as strength and stiffness, can easily be changed by changing amount or orientation of the reinforcement material. The downside is that such composites are often more expensive than conventional materials. Basic Properties: Density, viscosity and buoyancy Density : (weight per unit volume) is one of the most important physical properties of coating materials and other liquids and semi liquids. Density is important because it is a first-line indication of the ratios of components that make up a material. D = M/V As you heat a substance its molecules move farther apart and the substance becomes less dense. Solid liquid Second class /polymer dep./material physics gas IX chapter 1 General introduction Example: What is the mass of a 500.00 mL sample of seawater with a density of 1.025 g/mL? Buoyancy and Archimedes low : Any object, wholy or partially immersed in a fluid, is buoyed up by a force equal to the weight of the fluid displaced by the object. The upward force on a body immersed or partly immersed in a fluid. This low used for measuring of density of the solid materials For a fully submerged object, Archimedes' principle can be reformulated as follows, Second class /polymer dep./material physics X chapter 1 General introduction What is Viscosity? A measure of a material’s resistance to flow, and it is a measure of the resistance that one layer of liquid experiences when flowing over another layer. Substances with higher viscosity take longer to flow down the ramp. Application of Viscosity: *Viscosity is the most important property of motor oil. **Viscosity depends on temperature – Increase temperature will decrease the viscosity of the material. In the winter you need lower viscosity oil so the oil will flow better. In the summer, you need higher viscosity oil so during the higher summer temperatures it will not flow too fast. (If oil is too thin it does not adhere to the surfaces and lubricate the moving parts.) Second class /polymer dep./material physics