Recycling (Arcology)

advertisement

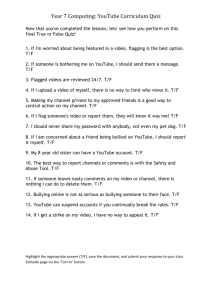

Recycling Recycling is the process of producing new products from used material in order to protect our environment. Following are various numbers of recyclable materials: 1. Plastic 2. Glass 3. Waste water 4. Metal Food and Beverage Containers 5. Paper There are various number of recycling systems which can be implemented on island in order to collect recyclable material from the general waste stream such as "drop-off centers", "buy-back centers" and "curbside collection".[1] Let’s suppose that to establish the composition of recyclable material in the waste stream on island, a waste was estimated and given as follow: S# Percentage Generated 1 2 Recyclable Material Plastic Glass 3 Waste 50% 4 Metal containers 7% 5 Paper 15% 3% 25% 1. Plastic Recycling http://www.youtube.com/watch?v=0THzy4d67SQ&feature=related Conveyer Washing Type Crushing U-shape screw Conveyer Washing and Impurities seperation Squeez type De-watering Washing and Impurities seperation Squeez type De-watering Screw Conveyer Crushing Blowing Cyclone Side Feeding Main Extruding Sub-Extruding Cooling Dehumidifying Cutting Storing Fig: 1 2. Glass Recycling Glass is sorted at material recycling facility into various colors, mainly Flint (clear glass), Green glass, and Brown / Amber glass. Glass is then sold to glass processors to be cleaned and crushed. The glass that has been processed is now known as cullet and is ready to be used in producing new glass. (http://www.youtube.com/watch?v=G1yaoeWtWJY) http://www.youtube.com/watch?v=6R8YObQbE88&feature=related Glass Containers Collection Mixing with Raw materials(Sand) Melted in Furnace at 1000 F˚ Delivered to Re-Processing Sent to Glass Factory Moulding/ mechanically blown Screening Crushing Packaging Contamination Seperation according to colors Fig: 2 3. Waste Water Treatment The waste water can be treated by number of following steps: Coagulation/flocculation- Raw water from terminal reservoirs is drawn into mixing basins at treatment plants where alum, polymer and sometimes lime and carbon dioxide are added. This process causes small particles to stick to one another, forming larger particles. Sedimentation- Over time, the now-larger particles become heavy enough to settle to the bottom of a basin from which sediment is removed. Filtration- The water is then filtered through layers of fine, granulated materials — either sand, or sand and coal, depending on the treatment plant. As smaller, suspended particles are removed, turbidity diminishes and clear water emerges. Disinfection- To protect against any bacteria, viruses and other microbes that might remain, disinfectant is added before the water flows into underground reservoirs throughout the distribution system. Corrosion control- pH is maintained by adding alkaline substances to reduce corrosion in the distribution system. <http://www.youtube.com/watch?v=9z14l51ISwg&feature=related> Stored Raw Water Home Coagulation Finihed Water Storage Sedimentation Disinfection Filteration Fig: 3 4. Metal Food and Beverage Containers Today it is cheaper, faster and more energy-efficient to recycle aluminum than ever before. The process of recycling aluminum cans is described below; Step#01 Aluminum cans are collected at residential drop-offs and by municipal pick-ups. Once cans arrive at the MRF (Material Recovery Facility) they will be sorted using a device called an eddy current. The eddy current briefly electrically charges they can cause it to repel from the device off a sorting line into an awaiting bin. After, they condense the cans into highly dense, 30-pound briquettes or 1,200-pound bales and ship them off to aluminum companies for melting. Step#02 At the aluminum companies, the condensed cans are shredded, crushed and stripped of their inside and outside decorations via a burning process. Then, the potato chip-sized pieces of aluminum are loaded into melting furnaces, where the recycled metal is blended with new, virgin aluminum. Step#03 The molten aluminum is then poured into 25-foot long ingots that weigh over 30,000 pounds. The ingots are fed into rolling mills that reduce the thickness of the metal from 20-plus inches to a sheet that is about 10/1,000 of an inch thick. Step#04 This metal is then coiled and shipped to can makers, who produce can bodies and lids. They, in turn, deliver cans to beverage companies for filling. Step#05 The new cans are then ready to return to store shelves in as little as 60 days, only to go through the entire recycling process again. (http://www.youtube.com/watch?v=1rXNdcJu-bY) Figure: 4 5. Paper Recycling Pulping: Adding water and applying mechanical action to separate fibers from each other. Screening: Using screens, with either slots or holes, to remove contaminants that are larger than pulp fibers. Centrifugal cleaning: Spinning the pulp slurry in cleaner cause materials that are denser than pulp fibers to move outward and be rejected. Flotation: Passing air bubbles through the pulp slurry, with a surfactant present, causes ink particles to collect with the foam on the surface. By removing contaminated foam, pulp is made brighter. This step is sometimes called de-inking. Kneading or dispersion: Mechanical action is applied to fragment contaminant particles. Washing: Small particles are removed by passing water through the pulp. Bleaching: If white paper is desired, bleaching uses peroxides or hydrosulfides to remove color from the pulp. Papermaking: The clean (and/or bleached) fiber is made into a "new" paper product in the same way that virgin paper is made. Dissolved air flotation: Process water is cleaned for reuse. Waste disposal: The unusable material left over, mainly ink, plastics, filler and short fibers, is called sludge. The sludge is buried in a landfill, burned to create energy at the paper mill or used as a fertilizer by local farmers. (http://www.youtube.com/watch?v=ETlZjOcsQIk) Used Paper Waste Disposal Sorting Disolved Air Flotation Pulping Paper making Screening Centrifugal Cleaning Bleaching Washing Flotation Dispersion Fig: 5 References 1. World War. "Recycling." Wikipedia, the Free Encyclopedia. Wikimedia Foundation, Inc, 22 Feb. 2011. Web. 24 Feb. 2011. <http://en.wikipedia.org/wiki/Recycling>. 2. "Treatment Process | Denver Water." Welcome to Denver Water. Web. 23 Feb. 2011. <http://www.denverwater.org/WaterQuality/TreatmentProcess/>. 3. "Recycle These Items - Waste Management - Public Works - Region of Peel." Region of Peel Working for Citizens in Brampton, Caledon and Mississauga. Web. 23 Feb. 2011. <http://www.peelregion.ca/pw/waste/garb-recy/recycle-items.htm>. 4. "Recyclable Materials Marketing- ReMM." Recyclable Materials Marketing - ReMM. Recyclable Materias Marketing, 2007. Web. 23 Feb. 2011. <http://www.remm.ca/facts.html>. 5. "YouTube - Ahmedabad Paper Factory." YouTube - Broadcast Yourself. Web. 23 Feb. 2011. <http://www.youtube.com/watch?v=ETlZjOcsQIk>. 6. "YouTube - Plastic Recycling Production Line with Shredder Recycling Equipment - Part1." YouTube Broadcast Yourself. Web. 23 Feb. 2011. <http://www.youtube.com/watch?v=0THzy4d67SQ&feature=related>. 7. "YouTube - Glass Recycling." YouTube - Broadcast <http://www.youtube.com/watch?v=G1yaoeWtWJY>. Yourself. Web. 23 Feb. 2011. 8. "YouTube - The Smashing Story of Recycling Glass." YouTube - Broadcast Yourself. Web. 23 Feb. 2011. <http://www.youtube.com/watch?v=6R8YObQbE88&feature=related>. 9. "YouTube - Wastewater Treatment." YouTube - Broadcast Yourself. Web. 23 Feb. 2011. <http://www.youtube.com/watch?v=v_aJWYfm4I4>. 10. "YouTube - The Water Treatment Process." YouTube - Broadcast Yourself. Web. 23 Feb. 2011. <http://www.youtube.com/watch?v=9z14l51ISwg&feature=related>. 11. "YouTube - Can Recycling." YouTube - Broadcast <http://www.youtube.com/watch?v=1rXNdcJu-bY>. Yourself. Web. 23 Feb. 2011.