emissions analysis

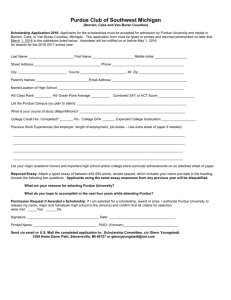

advertisement

National Test Facility for Fuels and Propulsion Aviation Technology, Purdue University See contact information, second page. NaTeF was funded through a $2.7M cooperative agreement with the Air Force Research Laboratory at Wright Patterson Air Force Base. The capabilities include engine test cells, engine test stands, a Materials Laboratory, and the Zucrow High Pressure Laboratory; all of these facilities are located at the Purdue University Airport. The fuels testing capabilities of NaTeF include: Engine testing: Engine operation with the following testing capacities (inside and outside NaTeF test cells): o Engines: small turbofan, turboprop, turbo-shaft, and piston engines o Advanced data acquisition for engine pressures, temperature, RPM, spool speeds, power, and ambient conditions o Dyne 500 HP eddy current dynamometer for piston and other shaft engine testing o Conditioned combustion air system for piston engine testing 2200 cfm volumetric flow rate Humidity control range: 45 to 90 degree dew point o Exhaust emissions for turbine and piston engines Five gas analyzer: CO, CO2, O2, NO, NOx, total hydrocarbon Particulate matter to 2.5 NM FTIR for specified hydrocarbons o Experimental fuel system for inside test cells o Detonation testing (piston, spark ignition engine) under development Zucrow High Pressure Laboratory capabilities (an ME test facility): o Turbine engine combustor study capabilities, including exhaust emissions Fuel characterization and Materials testing: Liquids - Fuel/oil testing: Most testing capabilities required to characterize fuel. Density, flashpoint, UV-Vis spectrum, FT-IR analysis, GC analysis, surface tension, TGA analysis. Polymer/non-metallic testing - on o-rings and flat stock Shore A durometer (hardness), density, tensile, FT-IR analysis, TGA analysis, Hyphenated TGA/FTIR analysis, ASTM compression testing, surface adhesion testing, Exposure testing of above properties o Ambient temperatures o Elevated temperatures to 200C utilizing ovens o Cold temperatures as low as -80C o Dimensional change following temperature exposure. Flight test Test operations utilizing a twin-engine Beechcraft Duchess, which may be flown in an experimental category, with the test plan and analysis to be overseen by NaTeF and AirTIES research groups. This aircraft can also be equipped to analyze exhaust emissions in the trail of other aircraft or atmospheric emissions. Flight test with Purdue fleet aircraft or external aircraft when circumstances allow for conversion to Experimental category. Services contracted through an outside organization, with both the research procedures and analysis of the results performed in close cooperation with the NaTeF and AirTIES research groups. Future testing capabilities in development: Hot fuels o Impact on components and materials o Effects on combustion properties Comparative Fuels Research (CFR) engine for octane analysis. The capabilities represented by this equipment are highly valued in the fuels industry; plans are under development to bring it to an operational stage in the future. Small engine dynamometer. The advent of unmanned aerial systems (UAVs) for DoD, government, and commercial applications is driving interest in development of small internal combustion powerplants that deliver high performance and efficiency. Specialized testing: In addition to the above services, the NaTeF group will develop specialized testing capabilities to meet research needs, whenever possible. Contacts: Purdue University faculty and personnel Prof. David L. Stanley, (765) 494 6266, dlstanley@purdue.edu; Project lead Prof. J. Mark Thom, (765) 494 9757, jmthom@purdue.edu; Experimental test operations Prof. Denver Lopp, (765) 494 6387, denver@purdue.edu; Collaborative relationships and proposals Prof. J. Michael Davis (765) 494 5715, davis212@purdue.edu; Engine / Test cell operations Prof. Mary Johnson, (765) 494 1064, Ph.D., mejohnson@purdue.edu, Exhaust emissions analysis Gozdem Kilaz, gkilaz@purdue.edu; Ph.D., Chemical Engineering, Chief Scientist of AirTIES Richard Simmons, rsimmon@purdue.edu; MS, Mechanical Engineering (Ph.D. researcher) Additional expertise Melanie Thom, (765) 743 9812, melanieathom@cs.com; Chemistry (consultant)