Cable & Patch Cord Installation Practices

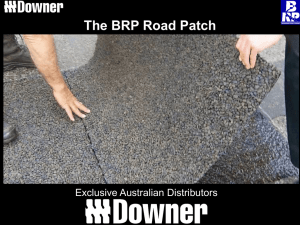

advertisement

Patch Cord Installation Practices This document has been produced by Brand-Rex to assist the installer with best practices for Patch Cord installation. Information within has been sourced from the Brand-Rex installation manual, many years experience in the industry and standards documents. Together this information should assist the installer and answer many of the usual questions surrounding patching installation. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 1 of 35 Revision Control Issue Date 1.0 01-04-12 BR_TSS_Patch_Cable_Installation_Pract ices Reason Document Creation April 2012 Updated by T.Simmons Page 2 of 35 Contents Section 1 Copper Patch Cords Content Page 1 CABLE INSTALLATION PRACTICES 1.1 1.2 1.3 1.4 1.5 Bend Radii Copper Pulling Forces and Twisting Dressing of Cables Cable Labelling Cable Protection 6 7 8 8 8 2 ADDITTIONAL RULLES FR 10GPLUS PATCH CABLES 2.1 2.2 2.3 Alien Crosstalk Mitigation Techniques Patch Cord Management 9 9 10 3 PATCHING GUIDELINES 3.1 3.2 3.3 3.4 Patching Good Practices Temporary Patches A Tidy Frame Routing Patch Cables 11 12 12 13 4 CABLE MANAGEMENT 4.1 4.2 4.3 4.4 Cable Management Bars Blanking Panels Angled V Panels High Density Patching Frame 14 15 15 16 Section 2 Fibre Patch Cords Content Page 5 TIA/EIA 568C-3 Optical Patch Cords 5.1 5.2 5.3 5.4 General Patch Cord Cable Patch Cord Connectors Termination Configuration 5.4.1 Duplex System 5.4.2 Simplex System 5.4.3 Array System 5.4.3.1 General 5.4.3.2 Optical Fibre Patch Cord 5.4.3.2.1 Type A Optical Fibre Patch Cord BR_TSS_Patch_Cable_Installation_Pract ices April 2012 18 18 18 18 18 18 19 19 19 Page 3 of 35 Section 2 Fibre Patch Cords (continued) Content Page 5.4.3.2.2 Type B Optical Fibre Patch Cord 5.4.3.2.3 Type C Optical Fibre Patch Cord 5.4.3.2.4 A to B Patch Cord (Standard) 5.4.3.2.5 A to A Patch Cord 5.4.3.3 Transition 6 FIBRE PATCH CORDS 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 Bend Radii Optical Losses 6.2.1 Macro Bending 6.2.2 Micro Bending Polished Ends 6.3.1 Polished Connector (PC) 6.3.2 Angled Polished Connector (APC) Fibre Types Connector Types Patch Cord Types 6.6.1 Simplex 6.6.2 Duplex Hybrid Patch Cords Fibre Breakout Cables Secure Fibre Patching 7 OPTICAL PATCH CORD MAINTENANCE 7.1 7.2 7.3 7.4 7.5 Lint Free Wipes Individual Pre-Saturated IPA Wipes Optical Fibre Cleaning Cassette & Tape Swabs Ferrule Cleaner 8 OPTICAL PATCH CORD TESTING 8.1 8.2 Optical Microscope Types of Fibre Faults 8.2.1 Chip 8.2.2 Crack 8.2.3 Scratch 8.2.4 Broken Fibre BR_TSS_Patch_Cable_Installation_Pract ices 20 20 21 21 22 23 24 24 25 25 26 26 27 27 28 28 29 30 30 31 31 32 33 34 34 35 35 April 2012 Page 4 of 35 Section 1 Copper Patch Cords BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 5 of 35 CABLE & PATCH CORD INSTALLATION PRACTICES 1.1. Bend Radii The bending radius is defined as a multiplication factor of the outside cable diameter. There are two relevant minimum bending radii: one for patch cord installation and one for the patch cord once it is installed (without mechanical load). It is important to note that the minimum permissible bend radii of a cable is greater during the installation / pulling in stage, when the cable is under tension, than it is when the cable is placed in its final position and is free from tension. This criteria is also applicable when installing/dressing patch cords. Minimum bend radii must be observed throughout the whole cable route in order to ensure that the design performance of the cable is not impaired. XR XR = min radius during installation 8 x sheath diameter IR= min radius installed 4 x sheath diameter IR It is also important to consider bend radii when determining the size of containment systems such as basket tray, conduit or trunking, as the system may have adequate capacity for the straight runs but be too small at the turns for the minimum bend radii to be observed. Tray work should have gussets fitted to the inside edge of corners and conduit systems constructed to ensure that minimum bend radius is not infringed. The same applies to containment within cabinets, around frames and between patch panels. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 6 of 35 1.2. Pulling Forces and Twisting Maximum pulling forces should not be infringed to ensure that the cable is not damaged or its performance impaired during installation. Ensure that adequate containment, patch management is available. Minimise the twisting, pulling and bending of patch cords during installation.. The following installation parameters must be observed for four pair cables this table should always be referenced for patch cord installation:Parameter Units 4 pair U/UTP Unit* 4 pair F/UTP Unit * 4 pair S/FTP Unit* Temperature rating: Installation Operation Storage oC oC oC 0 to 50 -20 to 60 -40 to 60 0 to 50 -20 to 60 -40 to 60 0 to 50 -20 to 60 -40 to 60 Min. bending radius During installation Installed mm mm 40 20 Max. pulling load N 85 GigaPlus 50 25 60 30 85 85 CAT6Plus Min. bending radius During installation Installed mm mm 50 25 Max. pulling load N 70 PIMF 70 35 95 10GPlus Min. bending radius During installation Installed mm mm Max. pulling load N Min. bending radius During installation Installed mm mm Max Pulling Load N 72 36 N/a N/a PIMF 65 32 98 N/a 10G Plus Zone Cable U/FTP N/a 45 N/a 22 N/a N/a N/a N/a 98 95 During installation, cable management precautions that should be observed include the elimination of cable stress caused by excessive tension, sharp bends and tightly bunched cords. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 7 of 35 Temperature variations should not exceed those stated above, it should be noted that attenuation increases with temperature, typically 0.4% per C for Cat5e cables. 1.3. Dressing of Cables Dressed into neat groups and fix into place using the patch management systems. It is good practice to keep the groups as small as possible; this will aid cable identification and future maintenance. 1.4. Cord Labelling ANSI/TIA/EIA 606A is the latest labelling standard that covers labelling standards across your cabling infrastructure. It does not mention that individual patch cords should be labelled but it can be good practice to do so. If you do choose to label, 606A states that the use of printed self-laminated wrap around labels is recommended. There are many guides available on the web that covers the requirements of this standard or a copy can be purchased at – http://global.ihs.com/search_res.cfm?RID=TIA&INPUT_DOC_NUMBER=TIA-606 1.5. Cord Protection Take care to prevent damage to cords during and after installation. Where possible all redundant cords should be removed. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 8 of 35 2. ADDITIONAL RULES FOR 10GPLUS CABLES 2.1. Alien Crosstalk Alien crosstalk (AXT) is electromagnetic noise that can occur in a cable that runs alongside one or more other signal-carrying cables. The term "alien" arises from the fact that this form of crosstalk occurs between different cables in a group or bundle, rather than between individual wires or circuits within a single cable. Alien crosstalk can be particularly troublesome because, unlike simple crosstalk caused by a single interfering signal, it cannot be eliminated by the phase cancellation techniques used in Digital Signal Processing. Alien crosstalk arises from multiple signals, from multiple cables and includes mixing products in which signals at innumerable frequencies blend with the originating signals. The result is a mix of electromagnetic interference that is too complex to be dealt with by Digital Signal Processing measures. Because it resembles noise rather than signals, alien crosstalk degrades the performance of a communications system by reducing the signal-to-noise ratio (SNR). 2.2. Mitigation Techniques Alien crosstalk can be minimized or eliminated by avoiding configurations in which cables are bundled together or run parallel to one another in close proximity. In the first part of the link is imperative and non-more so than the patch lead, not to run the cables or patch leads perfectly parallel to each other, or cable tie them together or dress them in cramped cable management products. Avoid cable management products that will compress or kink the cables and in the case of cable ties ensure that they are not over tensioned. If a cable tie has been over tightened then the balance of the cable will be affected. This will make this area of the cable susceptible to noise. Use patch panels that stagger the jacks or leave additional space between the jacks. The additional spacing will dramatically reduce the effects of alien crosstalk. Shielded solutions may well be one very practical approach in reducing alien crosstalk. The foil, and foil and braid types, will act as a screen to alien crosstalk. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 9 of 35 The use of shielded patch leads will dramatically reduce alien crosstalk and Brand-Rex recommends their use on all 10G Plus installations. As with any shielded system the earthing and bonding arrangements are paramount to their success and any shielded system must be installed and designed by trained and experienced installers of shielded systems. 2.3. Patch cord management When designing patch cord management systems it is important to understand what the maximum capacities and performance is required. Avoid running Copper and Fibre patch cords in the same management routes. Important Note Try not to mix cable types in the same paths as 10GPlus products. If you must lay 10GPlus cables in the same paths as CAT5 or CAT 6 cables then leave at least a 10mm space between them. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 10 of 35 3 Patching Guidelines 3.1 Patching Good Practice Ports 1-12 Ports 1-12 patch to the left side of the cabinet Ports 13-24 patch to the right side of the cabinet 1U Management Bar for every 2 panels of patching Copper and Fibre patching to be separated as much as possible Beware of servers on rails that need to move Avoid obstructing removal switch blades and cooling fans Use correct lengths to avoid bird’s nest Make sure correct patching cabinets are used Always remove redundant cords Ensure no service exists before disconnecting or re-patching Always use Brand-Rex patch cables on a Brand-Rex installation to keep the 25 Year Warranty Avoid “through Cabling” patching from one side of the frame to the other should be avoided if possible. If unavoidable, make sure the cabinets are installed with sufficient management bars to cope i.e. 2U top, middle and bottom. BR_TSS_Patch_Cable_Installation_Pract ices Ports 13-24 April 2012 Page 11 of 35 3.2. Temporary Patch Cables If allowed, temporary patch cables can mount up to look like this. One thing leads to another and 6 months after a new installation you’re faced with an unmanageable patching frame and ££££’s of re-patching bills. Time to fix faults and moves and changes can take up to 10 times longer. After all “Time is money”!!! Cables protruding from the cab can also be a Health & Safety issue as well as increase the risk of accidental disconnection of circuits. 3.3. A Tidy Frame Keep your frame looking like this and your patching can be achieved in a fraction of the time. Unique ID’s on patch cables and the use of a patching database will help quickly identify cables which will save time and money on each patch change. With a tidy frame, capacity can also easily be monitored. Label patch cables with a unique number to help identify leads. Use the correct Category patch cords to match the installed system. The link will only be as good as the slowest part of the network. Avoid sharp bends in cables, this will increase attenuation. Make sure cables are tidied inside cabs. Cables protruding can cause trip hazards and may get trapped in floor tiles. Use Brand-Rex Angled V panel to reduce number of bends in patch cords Never install “Temporary” patches, they never get patched correctly and are usually left on the frame. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 12 of 35 3.4. Routing Cables Follow the 10 Rule Guide to maintaining patching frames and you will help keep your frame in a good condition. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 13 of 35 4 CABLE MANAGEMENT 4.1 Cable Management Bars Ensure there are sufficient cable management bars installed in the cabinets. Brand-Rex manufacture a range of panels as above. If using regular 24 port copper patch panels it is recommended to install 1 x 1U Cable management bar for every 2 patch panels. If using the Brand-Rex angled V 24 port patch panels it is not necessary to use a management bar, however a finger system should be installed vertically to take the weight of the patch cables and keep them managed. Most patching frames require inter-cab patching. Routing these longer patch cables through the cabinet 1U management bars should be avoided. To enable best practices a 2U management bar should be installed Top, Middle and Bottom of the frame, this will avoid congestion for patch cables within the cabinet. It should be noted that this is best practice and the use of 2U cable management bars will greatly reduce the frames capacity. A well designed system should avoid inter-cabinet patching with a single patch cord as much as possible, this can be achieved by distributing the services regularly BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 14 of 35 4.2 Blanking Panels Brand-Rex also manufactures a range of Blanking panels for cabinets. Primarily these are designed to fill U space in cabinets to allow the correct circulation of air and allow the air conditioning to operate efficiently. Another good feature of the blanking panel is they prevent temporary patch cables being installed from front to back, can help reserve U space for future panels and keep the cabs/frames looking neat and tidy. 4.3 Brand-Rex Angled V Panels Brand-Rex have designed an Angled V Panel to assist with the growing demands within a patching cabinet. The panel allows more patch panels in each rack as the modules are angled to the side so that patch cables naturally flow into the management at the side (should be used with finger management). As the modules are angled to the side the 90 degree bend that normally occurs with patch cables is removed, when installing 10G systems every loss saving counts. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 15 of 35 4.4 Brand-Rex High Density Patching Frame Vertical Finger Management The Brand-Rex High density patching frame is designed to house a higher number of patch panels than a regular patching rack. By using the Angled V panel seen in section 4.3 along with the vertical finger management system you no longer need the 1U cable management bars, this could save as much as 8U per rack. If patching between different racks it is still recommended to use a 2U management bar to allow for “through” patching. The high Density patching Frame can be used for both Copper and Fibre installations. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 16 of 35 Section 2 Fibre Patch Cords BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 17 of 35 5 TIA/EIA 568-C.3 Optical Patch Cords Section 5 has been taken directly from the 568C-3 standard. Heading numbers are as they are found in the standard document. OPTICAL FIBER PATCH CORDS 5.1 General This clause contains the performance specifications for optical fiber patch cords recognized in premises cabling standards. These patch cords are used to connect optical fiber links at crossconnects, interconnects, and to connect telecommunications equipment. NOTE - Requirements for application specific assemblies are outside the scope of this Standard. 5.2 Patch cord cable The optical fiber patch cord shall contain the same number of fibers as the connector used (e.g., duplex connectors using duplex patch cord cable), be of the same fiber type as the optical fiber cabling, of an indoor construction, and meet the requirements of subclauses 3.2 and 3.3.1. 5.3 Patch cord connectors The patch cord connector shall meet the requirements of subclause 4.2. 5.4 Termination configuration 5.4.1 Duplex system Duplex optical fiber patch cords shall be of an orientation such that Position A goes to Position B on one fiber, and Position B goes to Position A on the other fiber of the fiber pair (figure 3). Each end of the optical fiber patch cord shall be identified to indicate Position A and Position B if the connector can be separated into its simplex components. For alternate connector designs utilizing latches, the latch defines the positioning in the same manner as the keys. Figure 3 - A-to-B duplex optical fiber patch cord NOTE – SC connectors are shown, but this assembly may be built using any duplex single-fiber connectors or connectors with two fixed fibers. 5.4.2 Simplex system The connector that plugs into the receiver shall be considered Position A, and the connector that plugs into the transmitter shall be considered Position B. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 18 of 35 5.4.3 Array system 5.4.3.1 General Each of the three array system methods illustrated in ANSI/TIA-568-C.0, requires a specific combination of components (array patch cables, transitions, duplex patch cords) to maintain polarity. Some of the components are common to other connectivity methods such as duplex systems. 5.4.3.2 Optical fiber cable or patch cord The cables or patch cords should be clearly identified. NOTE - The patch cord shown is unpinned on both ends. In some instances, such as when supporting parallel signals, it may be necessary to use a combination of unpinned and pinned connectors on cables and patch cords. (Move in general of cables) 5.4.3.2.1 Type-A optical fiber cable or patch cord As shown in figure 4, a Type-A connector patch cord has a sequential number assigned to each fiber as follows: a) On one end of the patch cord, the fibers are fixed within the array connector in consecutive number (1,2,3,4…12) from left to right as viewed looking at the end-face of the connector with the connector key up. b) On the other end of the patch cord, the fibers are fixed within the array connector also in consecutive number (1,2,3,4…12) from left to right as viewed looking at the end-face of the connector with the connector key up. Figure 4 - Type-A optical fiber cable or patch cord (key-up to key-down) BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 19 of 35 5.4.3.2.2 Type-B optical fiber cable or patch cord As shown in Figure 8, a Type-B array connector patch cord has a sequential number assigned to each fiber as follows: a) On one end of the cable, the fibers are fixed within the array connector in consecutive number (1,2,3,4…12) from left to right as viewed looking at the end-face of the connector with the connector key up. b) On the other end of the cable, the fibers are fixed within the array connector in reverse consecutive number (12,11,10,9…1) from left to right as viewed looking at the end-face of the connector with the connector key up. When MPO connectors are used in the construction of these cables they shall be flat polished Figure 5 - Type-B optical fiber cables or patch cord (key-up to key-down) 5.4.3.2.3 Type-C optical fiber cable or patch cord As shown in figure 9, Type-C patch cords have a sequential number assigned to each fiber as follows: a) On one end of the cable, the fibers are fixed within the array connector in consecutive number (1,2,3,4…12) from left to right as viewed looking at the end-face of the connector with the connector key up. b) On the other end of the cable, the fibers are pair-wise flipped within the array connector (2,1; 4,3; 6,5…12,11) from left to right as viewed looking at the end-face of the connector with the connector key up. Figure 6 - Type-C optical fiber cable or patch cord (pair-wise flipped, key-up to key-down) BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 20 of 35 5.4.3.2.4 A-to-B patch cord (standard duplex patch cord) The A-to-B patch cords shall be built as specified in subclause 5.4.1. 5.4.3.2.5 A-to-A duplex patch cord As shown in figure 7, A-to-A duplex patch cords shall be built as specified in subclause 5.4.1, except Position A shall be routed to Position A and Position B routed to Position B. A-to-A patch cords do not reverse the fiber positions. The A-to-A Duplex optical fiber patch cords shall be of an orientation such that Position A goes to Position A on one fiber, and Position B goes to Position B on the other fiber of the fiber pair (figure 3).The A-to-A duplex patch cords shall be clearly identified (by color or prominent labeling) to distinguish them from A-to-B patch cords. NOTE – SC connectors are shown, but this assembly may be built using any duplex single-fiber connectors or connectors with two fixed fibers. Figure 7 - A-to-A duplex optical fiber patch cord BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 21 of 35 5.4.3.3 Transition As shown in figure 5, transitions have a sequential number assigned to each fiber as follows: a) On one end of the transition the fibers are fixed within the array connector in consecutive number (1,2,3,4…12) from left to right as viewed looking at the end-face of the connector with the connector key up. b) On the other end of the transition the fibers are fixed within the connectors in consecutive numbering (1,2; 3,4; 5,6…11,12) from left to right as viewed looking through the adapters with the adapter key up. Figure 8 - Array optical fiber transition NOTES 1 – SC connectors are illustrated; however this assembly may use single-fiber connectors or connectors with two fixed fibers. 2 – For ease of illustration, this transition is shown with duplex adapters, although they are not necessarily part of the assembly BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 22 of 35 6 FIBRE PATCH CORDS 6.1 Bend Radii Due to the sensitivity of most Fibre the bend radii is different to that of copper. The bending radius is defined as a multiplication factor of the outside cable diameter. There are two relevant minimum bending radii: one for patch cord installation and one for the patch cord once it is installed (without mechanical load). It is important to note that the minimum permissible bend radii of a cable is greater during the installation / pulling in stage, when the cable is under tension, than it is when the cable is placed in its final position and is free from tension. This criteria is also applicable when installing/dressing patch cords. Minimum bend radii must be observed throughout the whole cable route in order to ensure that the design performance of the cable is not impaired. XR = min radius during installation 15 x sheath diameter XR IR= min radius installed 10 x sheath diameter IR It is also important to consider bend radii when determining the size of containment systems such as basket tray, conduit or trunking, as the system may have adequate capacity for the straight runs but be too small at the turns for the minimum bend radii to be observed. Tray work should have gussets fitted to the inside edge of corners and conduit systems constructed to ensure that minimum bend radius is not infringed. The same applies to containment within cabinets, around frames and between patch panels. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 23 of 35 6.2. Optical Losses All optical fibres exhibit some loss or attenuation of the transmitted signal, much of this loss is intrinsic, that is due to the glass itself. However other conditions such as excessive bending connectors and splices also contribute to the loss. 6.2.1. Macro Bending Macro bending loss shows up when fibre bend radius decreases, as the bend gets tighter light rays within the fibre begin reflecting at angles allowing them to pass through the cladding. The more the fibre is bent the higher the attenuation. 6.2.2. Micro Bending Micro bending losses are caused by from stresses on the fibre such as tight clamps and tie wraps pressing against the fibre. They can also be caused by deviations in the core, measured from the axis of the fibre. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 24 of 35 6.3 Polished ends There are 2 main typed of polished end for Fibre connectors, see below. The Polished Connector (PC) is commonly used in Multimode cables and the Angled Polished Connector (APC) is an option with the singlemode connectors. 6.3.1 Polished Connector (PC) 6.3.2 Angled Polished Connector BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 25 of 35 6.4 Fibre Types Brand-Rex manufacture all types of Fibre Optic cable that may be required in the DataCentre. Below is a table highlighting the types available. Fibre Patch Cords are available in any fibre type. OM1 62.5/125 OM2 50/125 OM3 50/125 OM4 50/125 OS1 8/25 OS2 8/125 62.5/125 was the industry standard 10 years ago however OM3 has now become the customer choice as it more than meets the requirements of todays network infrastructure. As network demands are increasing the use of OM4 fibre is becoming more popular. NOTE: Make sure that the correct choice of cable is made when purchasing new Fibre patch cords. If possible try to keep a standard across your site to avoid future confusion. 6.5 Connector Types Over the years there have been many different types of connector used to terminate the fibre optic cable. Below is a list of some of the more popular. Just as 62.5/125 multimode fibre was the most commonly installed cable, the SC connector was the most popular. The LC connector is now the preferred connector for all new installations. However legacy cabling and equipment mean that you may need a cable to convert from one type to another, see section 6.4 for the types available. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 26 of 35 6.6 Patch Cord Types 6.6.1 Simplex Simplex is usually used to describe a single strand of Fiber Optic cable. This is sometimes used when a signal only needs to go in one direction, like a simple video feed from a security camera. 6.6.2 Duplex Duplex (sometimes called "zipcord") is two strands of Fiber Optic cable joined by a thin connection between the two jackets. This is much more commonly used than simplex as with two fibers you can get synchronous communication between devices. Duplex cables are often labeled with A and B to determine which is the transmit and which is the receive. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 27 of 35 6.7 Hybrid Patch Cords As explained in section 6.3 is may be likely that you will need to convert from one connector to another when patching a circuit. It may be because you have an LC presentation for your cabling infrastructure and your equipment only has SC or ST connectors. If the ports on your equipment are modular, it may be best to upgrade to the LC module to try and keep the requirements for patching infrastructure as simple/standard as possible. Brand-Rex manufacture all cable varieties below and in a range of lengths. 1m, 2m, 3m and 5m are the standard lengths however different sizes can easily be supplied. Cable Varieties (Duplex) LC-LC LC-SC LC-MTRJ 6.8 SC-ST ST-MTRJ MTRJ-MTRJ ST-ST MTRJ-SC LC-ST FC-FC SC-SC MTP-MTP Fibre Breakout Cables Although not really a patch cable, Fibre breakout cables are being use more commonly in the data centres as part of the new MTP design. A 12 core cable between point A and B can be installed and then a breakout assembly connected via an MTP connector. Therefore a fibre core can easily be patched to 6 LC duplex ports on a piece of equipment. This is a simple way to install 12 cores using a plug and play design, removing the need to field terminate or splice on site. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 28 of 35 6.9 Secure Fibre Patching Secure Fibre patching is a new product from Brand-Rex which gives you the opportunity to lock patch cords in place or block ports that you don’t want used. This product has a high value in secure customer environments or for important/critical circuits that should not be accidently disconnected. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 29 of 35 7 OPTICAL PATCH CORD MAINTENENCE It is highly important to ensure you have a clean Fibre Optic infrastructure. Cleaning new and existing patch cords before each insertion into a coupler is critical. There are also methods of cleaning the fibre coupler to guarantee you are maintaining your physical network in the best possible way. Section 7 highlights some of the products that can be used to maintain your fibre network. 7.1 Lint Free Wipes Lint free wipes are one of the most basic methods of cleaning your fibres, Lint free and non abrasive to ensure you are left with a clean fibre. To be used with IPA solution. 7.2 Individual Pre-saturated IPA Wpies IPA wipes provide the same solution as the Lint Free wipes above but are supplied pre-saturated for convienience. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 30 of 35 7.3 Optical Fibre Cleaning Cassette and Tape Great alternative to alcohol or other cleaning solutions. Offers lint-free, clean room grade cleaning media which effectively removes dirt, dust, oil, grease and debris from connector end faces. Resilient rubber pad beneath the cleaning surface prevents scratching. Sliding cover protects the cleaning media from contamination when not in use. Reel refills available. 7.4 Swabs Used for cleaning connector ferrule end faces, adaptors and difficult areas. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 31 of 35 7.5 Ferrule cleaner BR_TSS_Patch_Cable_Installation_Pract ices Easy pushing motion engages connector and initiates cleaner. Minimum of 800 cleans Made from anti static resin Cleaning micro fibers are densely stranded and debris free. Extendable tip allows acces to hard to reach recessed connectors. Cleaning system rotates 180 degrees for optimim cleaning. Audible click to inform when engaged. Compliant with EU/95/2002/EC Directive (RoHS). Effective with a variety of contaminants. April 2012 Page 32 of 35 8 OPTICAL PATCH CORD TESTING 8.1 Optical Microscope Optical microscopes come in a variety of shapes and sizes. Pictured above is an example of 2 portable units. Each have connectors that can be easily changed to suit the type of fibre connector being checked. When looking through the microscope you should be looking for obvious signs of dirt and contaminants. After the connector has been cleaned you should see a perfect surface. Section 8.2 indicates some of the more severe faults that can be found when viewing the connectors. Before Clean After Clean Without the use of a microscope it may be that by blowing on the connector or rubbing it on your shirt may be good enough but such actions lead to the image on the left. By using the microscope it’s clear to see the contaminants on the surface. A clean or maybe a re-polish may be needed to bring this connector up to spec. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 33 of 35 8.2 Types of Fibre Faults 8.2.1 Chip These show up as dark areas off to one side of the fibre. They are usually caused by poor cleaving of the excess fibre, resulting in a crack extending beneath the connector end face. Because the ceramic is harder than the fibre, this section of the fibre cannot be polished and so remains dark. Acceptance: Chips on the core or on the inner cladding are unacceptable. Chips in the outer cladding region extending more than 25% round the circumference are also unacceptable. 8.2.2 Crack Dark lines, often going straight through the middle of the core, or looking like crazy paving indicate cracks. These often show up more clearly when the connector is back illuminated. These cracks are caused by excessive heating or uneven curing of the epoxy resin. They are rarely seen when a properly temperature controlled curing oven is used, but are much more common if heat guns are used. Acceptance: Cracks on the core or on the inner cladding are unacceptable. Cracks in the outer cladding region extending more than 25% round the circumference are also unacceptable. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 34 of 35 8.2.3 Scratch When multiple lines run parallel to each other this usually indicates that the end face is scratched. This may be due to dirt and dust contaminating the polishing paper, or by neglecting to clean the polishing puck and connector face when moving from a coarse grade of lapping film to a finer one. Acceptance: The core should be free from scratch defects. 8.2.4 Broken Fibre If the fibre is broken, no light will get through. This will result in a dark ring from the cladding to the core of the fibre. Acceptance: Broken fibres are unacceptable. If further assistance/guidance is required then please contact our Technical support team on techsupport@brand-rex.com and your enquiry will be dealt with promptly with a relevant engineer assigned. More information on everything from Datasheets and White Papers to our latest training videos can also be found on the Brand-Rex website www.brand-rex.com. BR_TSS_Patch_Cable_Installation_Pract ices April 2012 Page 35 of 35

![Pumpkin Patch - L2 exam summary questions[1]](http://s3.studylib.net/store/data/006891404_1-eaba8a01ed43ce8c58f5173adc5f257b-300x300.png)