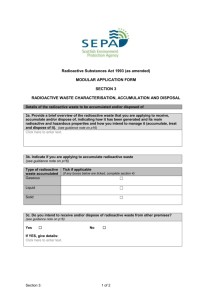

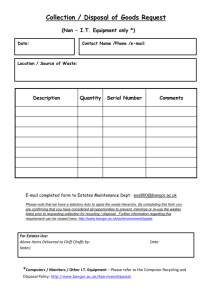

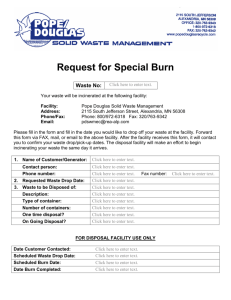

Figure 4-1. Waste Acceptance Process

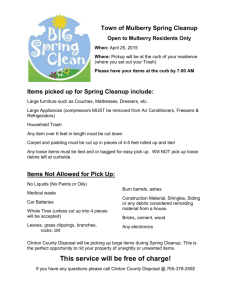

advertisement