Friction_HW1_1_2

Marc Desjardins

Tribology HW#1

10/4/2012

1.

Write a brief essay describing how and explaining why the surface and near surface regions of a solid material are different from the bulk of the same material?

The surface and near surface regions of a solid material can differ chemically and in atomic structure from the bulk of the same material. In metals, which are prevalent in engineering, the bulk structure will be made up of mainly the bulk material (e.g. copper, iron, cobalt) in organized lattice structure. Depending on the manufacturing process used there may be a layer of workhardened/plastically deformed material between 1-100 microns thick. Moving outward to the surface of the material, an amorphous microcrystalline layer (Beilby Layer) of the material will exist.

This layer is caused by the melting and flow of the asperities during machining and will be approximately 1-10 nanometers thick. On top of the Beilby layer sits an oxide layer 10-100 nanometers thick where the metal has oxidized due to the expose to the environment. Finally the top layer is about 1 nanometer thick and consists of water vapor or hydrocarbons that have either condensed on the object or chemically bonded.

2. Do some research on profilometers used to characterize the roughness characteristics of solid surfaces and write a short essay describing some of the key features of currently available models.

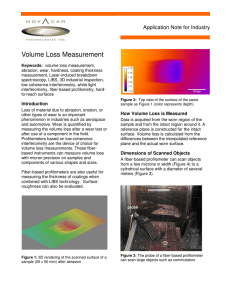

Profilometers can be broken down into 3 categories; contact, non-contact and both. The features (accuracy, range, output) and type of profilometer can be very industry specific. In a contact profilometer, a stylus moves vertically while it is in contact with a sample and moves laterally for a specific distance and contact force. The small vertical movements are converted into digital signals and stored. One feature of many contact profilometers includes their range (height and area) and resolution. A typical contact profilometer can operate and measure asperities of 1 mm to 1 nanometer in height. Most profilometers have small ranges in measurable area. A typical profilometer is capable of measuring areas up to 4 cm 2 . Many contact profilometers are easy to use and can convert the measured data into 2-dimensional and 3-dimensional images. Most contact profilometers strive to use very low stylus forces so that the instrument can be used on a wider range of materials.

Non-contact profilometers do not use styli like contact profilometers but provide much of the same information. A non-contact profilometer can use phase shift, white light or laser interferometer systems to deliver the surface roughness, 2D and 3D images, contours, and other surface dimensional features similar to a contact profilometer. Many profilometers have automatic or manual adjusting capability for different ranges of measurement. Other features of the many profilometers include the ability to dampen vibrations and create a vacuum for ultra-accurate measurements.