Homework7_#4_Sarria

Carlos Sarria

MANE6940

Page

Homework 7, Problem 4

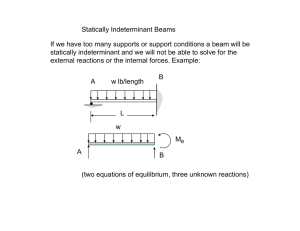

Consider a cantilever beam (length L=1m, breadth b=0.1m, height 2c=0.1m, E=2e11 Pa, ν=0.3,

ρ=7850kg/m 3 ). A concentrated transverse downward load F(N) is applied on the free end of the beam. a) Assume a sufficiently small value of the applied force so that the yield stress of σ y

=400MPa is approached but nowhere exceeded and compute the deformation of the beam. Then, increase the value of F slightly and just enough to start producing yielding (you should see the appearance of a boundary separating regions of elastic and plastic deformation in the beam) and compute the deformation of the beam. Then, continue increasing the load to make the plastic zone grow until it spans the entire cross section of the beam.

Using the Maple Worksheet from HW5, we can easily calculate the deflection using Equation 1and

Equation 2, assuming a load P of 1000N.

Equation 1: Horizontal deflection of beam

Equation 2: Vertical deflection of beam

Figure 1 shows the vertical deflection plot, with a maximum displacement of 2e-4m at the free end of

the beam.

Figure 1: Vertical deflection plot

Using Hooke’s Law we can calculate the expressions for the stress tensor components to verify maximum values don’t exceed the material’s yield strength. Lines 5 through 8 in the

HW07_#4_Sarria.pdf file shows the expressions used. The calculated maximum values are:

σ xx

=6MPa; σ yy

=1MPa; σ xy

=0.15MPa.

These values suggest that the beam is far enough from the yield point.

To calculate the required force to start yielding of the material, we use Equation 3.

Equation 3: Required force to yield

𝐹

𝐸

=

2 ∗ 𝜎 𝑦

∗ 𝑏 ∗ 𝑐

2

3 ∗ 𝐿

The value of this force is 66,667N (see line 12) from the HW07_#4_Sarria.pdf file. To verify that yielding has just started, we can once again use Hooke’s Law to calculate σ xx

. Figure 2 shows that the maximum

σ xx is 400MP, which is the yield stress of the material.

Figure 2: Sxx Plot

To calculate the tip deflection when the load is equal to F

E

Equation 4: Tip deflection at yield stress

Equation 5: Deflection at yield point

Δ e

is the calculated tip deflection when F=Fe, and its value is 0.013m.

As we let the force 𝐹 → 𝐹

𝑈

, where F

U

is the ultimate load required to obtain unconstrained plastic flow.

Equation 6 shows how to calculate this value, which is 1*10

5 N.

Equation 6: Ultimate load

𝐹

𝑈

=

3 ∗ 𝐹

𝐸

2

Using Equation 4 with a value of F less than F

U

, for example 99KN, we obtain a deflection of 0.029m.

b) Approximate the uniaxial stress-strain curve of the material by a bilinear function and use the finite element method to solve the same problems as above.

A force of 80,000N was applied in the negative Y direction. It is higher than the predicted -67000N

shows the plastic strain due to the applied force.

Figure 3: Von Mises Stress

Figure 4: Plastic strain

As we increase the load to -120000N, we can see how the plastic region spans across the entire cross

section of the beam. Figure 5 shows the plastic stress regions.

Figure 5: Von mises stress plot

Figure 6 shows the resulting plastic strain.

Figure 6: Plastic Strain