File - Professional Writing Portfolio by Joy Rebustes

advertisement

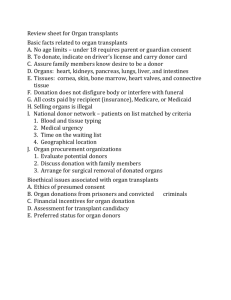

Rebustes 1 Modern Organ Replication Methods Investigating the Development of Artificial Organs for Transplants ______________________________________________________________________________ Joy Rebustes, Undergraduate Mechanical Engineering Student, Northeastern University Abstract There is a constant shortage of donated organs for transplant patients. The waiting list has significantly grown since 1989. Science and engineering are researching ways to eradicate this problem by creating artificial organs. Three primary methods are discussed in this paper: organ scaffolds, fully mechanical organ replacements and cell printed organs. Several factors are taken into account, such as feasibility, organ development time, ease of development, compatibility with the human body, and length of life. Out of these factors, the organ development time is most important: there is a wide demand that must be met for patients. While each method has its own advantages, cell printing is seen to have the most potential for creating a fully functional artificial organ. Keywords 3D Printing: Method of creating 3D parts using a computer generated image and printing that image using a 3D printer Computer-Aided Design (CAD): Designing a part or assembly using software programs such as AutoCAD or Solidworks Scaffold: A part that acts as a ‘skeleton’ for cells to rapidly grow on Decellurization: Removing the living cells from tissue in order to achieve a collagen/elastic ‘skeleton’ for which to rapidly grow cells on I. Introduction Each day, about 18 people in the United States die while waiting for an organ transplant. There is a constant shortage of donors, especially for children from the ages of 1 to 17. [1] While there has been a positive trend in people signing up to be organ donors, there is still a giant gap Rebustes 2 between these transplants and waiting list. A transplant candidate can wait from only a few days, to many years, depending on availability and level of the sickness of patient. The chart below from the U.S. Department of Health and Human Services demonstrates this[1]: Figure 1: Organ Transplant Chart[1] While there has been a slight increase in donors and transplants, the waiting list has skyrocketed since 1989. One way that doctors have tried to expedite the process is by attempting to make these organs more adaptable to any patient. This method is called decellurization, where the host cells are removed to create a collagen structure base. This base is then injected with stem cells taken from the patient in need and developed into a fully functioning live organ. This method is more than regular whole organ transplant because there is significantly lower chance of a negative reaction in the recipient[2]. On the other hand, this method still requires donors and therefore a long waiting list. The system needs to be improved. For every organ that becomes available, hundreds of thousands of people are waiting to receive it. Science and engineering have been working hard trying to close the gap using technology instead of depending on organ donations. By relying on Rebustes 3 technology, patients will be able to have needed organs much quicker and the organ trafficking in the black market may even be drastically reduced. II. Presented Methods A. Artificial Scaffolding One of these new alternatives includes creating artificial scaffold. A scaffold is a skeleton structure on which cells may grow, similar to the organ decellurization method. The challenge with artificial scaffolding is creating a 3D structure out of materials that the human body will not reject. Two methods of creating these scaffolds are being investigated: 3D printing and 3D bioplotting, each with their own advantages. 1. 3D Printed Scaffolds There are several kinds of 3D printers in the world, however the most common one used for biomedical applications is a powder based machine. First, a computer generated image of a 3D object is formed using a Computer Aided Design (CAD) program, and then inputted into the printer. The manufacturing process begins with a layer of powder. This powder is bonded together with a solvent dispensed by an inkjet print head, creating a very thin slice of the object. By binding fused powder layers numerous times, a 3D object can be achieved. When the object is completed, it requires post treatment in order to remove the extra powder and supports required to uphold the shape of the object. 3D printing allows a variety of shapes that are able to be acquired. Rebustes 4 The effectiveness of this method can be seen with the successful replication of a human heart. Using a CT and MRI scan, several views of a patient’s heart with a congenital defect was taken. A 3D model was formed using CAD and recreated in physical form using 3D Figure 2: CAD rendering of a heart [3] printing (as seen in Figure 2). An elastomer and adhesive is alternatively poured and integrated into the heart using a vacuum machine. Then the model can be bent to break the original scaffold, leaving a Figure 3: 3D Printed Heart with elastomer[3] completely smooth, slightly elastic heart (Figure 3). In these figures, the arrow points to the congenital defect in this particular patient, depicting the accuracy of the printed heart. The heart was proven to be able to slight expansion and compression to mimic a beating heart, using an inflated balloon[3]. While this achievement looked at this particular patient’s congenital defect, it shows a promising start to replicating a real heart. Instead of an elastomer, a cell matrix containing living cells of the patient and other substances to promote growth would be applied on the skeleton instead. If the 3D printing method is mastered, the need to wait for available organs might be over. However, there are other better ways to create an artificial scaffold. 2. Bioplotted Scaffolds Bioplotting is also “printed” layer by layer using a CAD model, however the dispenser distributes a viscous plotting material into a liquid medium. The densities of these two Rebustes 5 substances are the same to remove the need of temporary supports in the 3D printing. Bioplotting allows for a wider variety of materials for models, and can make similar structures to 3D printing. The post treatment time for bioplotted structures is also significantly less, allowing for overall less time to get an organ to a patient: crucial for those who are very sick and waiting. In a particular study creating two structures of the same shape and size, the 3D printed object needed almost 20 hours compared to the bioplotted object, which required only 30 minutes. When tested, the cell growth on each of the scaffolds was about the same rate, which points researchers to lean toward bioplotting as the superior method for organ scaffolding. However, it is a newer technology that Figure 4: Magnified view of 3D printed scaffold (top) and a 3D bioplotted similar scaffold (bottom) [4] requires more research. There are more 3D printers available than bioplotters, which makes it harder for a wider spread of researchers to work with this new machine. 3. Drawbacks of the Scaffolding Method While there have been many promising developments with artificial scaffolding, there are still drawbacks. The cellular growth on the scaffolds easily varies. To create a perfect, new organ, the cells must grow uniformly throughout the skeleton. In addition, the natural variance of cell types in different locations in organs is hard to recreate. Also, with rigid scaffolds, contractile tissues, such as in the heart, will have much difficulty moving[5]. Rebustes 6 B. Mechanical Organs 1. BioLung and SynCardia Instead of scaffolds, some have ventured to create fully mechanical organs, requiring no injection of cells. The BioLung weighs less than a pound and is incorporated into a vest that the patient wears. The BioLung is directly attached to the patient’s cannulae, where gas exchange can occur with the lung’s bundles of hollow fibers full of oxygen. A graphical depiction of the BioLung may be seen in Figure 5. A completely mechanical organ diminishes any need for organs or cells from either patient Figure 5: Diagram of the BioLung [6] temporary stand-in to the or donor. However, most mechanical organs serve as a actual transplant, such as the SynCardia heart in Figure 6. As seen, it resembles a real heart, but is still a long way from being a permanent solution to heart problems. Though it does save lives of patients Figure 6: Diagram of the BioLung [6] who need assistance until a real heart is available, it is far more preferable to have the true transplant than multiple surgeries in the cardiac area[6]. 2. Drawbacks of Mechanical Organs Will artificial organ replication ever be as functional as natural development? Currently, this is too difficult to know. Natural contractile movement is often too difficult to replicate and materials that will not be attacked by a body’s immune system are rare. All organs have specific Rebustes 7 placement of various cells, which has proved to be very difficult to develop in an artificial scaffold, and fully mechanical organs do not have the longevity that living replicating cells do. C. Cell Printing Science has been able to create a new method incorporating both 3D printing and natural cells with a layer by layer cell printing method. The printing material is called ‘bioink,’ a culture medium of endothelial cells. The bioink is printed layer by layer into 3D gel to create dense, functional, fused cell tubes.[5] This method has been successful with endothelial, smooth muscles, and stem cells. Again, this method also requires CAD for a 3D model and transferring the data to the organ printer. The bioink will vary depending Figure 7: Cell Arrangement to Make 3D Parts [5] on the tube being creating, from the type of cell, to the medium to control growth. However, this method has only gone so far as to create tube shaped parts of the larger organs. Figure 7 shows the current arrangement of cell growth. As seen, they are either cube shaped, which does not appear naturally in human tissue, or tube shaped. Each part is printed layer by layer. While tube shaped tissues do exist in the human body, the other various shapes still must be developed to create fully functioning organs. Much more research is worth looking into for this technology: it has the most potential to being a successful replacement for donors. When printing with cells, there is no worry for finding human-friendly materials, requires no post treatment after printing, can be adapted for each patient, while being less artificial than the products of other methods. With time and more research, there will be a chance that donors will no longer be needed, and more lives can be saved. Rebustes 8 III. Conclusions Overall, much research is still needed to create an efficient method to eradicate the gap between transplant patients and donors. Fully mechanical organs only survive for a period of time, and having multiple surgeries put patients at risk. While printed scaffolds mimicking decellurized organs have been the primary focus of research for tissue engineering, there are still too many factors that need to be overcome for it to be successful. These includes finding materials that the human body will not reject, endurance of the structure, and natural organ movement that must be adjusted for each new kind of organ. The biggest challenge for scaffolding is especially natural organ movement due to its rigid skeleton. Therefore, focusing on other methods, such as cell printing, would be the most logical path to developing a fully artificial transplant organ. Cell printing may be the future for artificial organ transplants. While tube shaped organ parts are the only current development, the possibilities this method offers allow for a more natural full organ. Cell printing eliminates the search for body-friendly materials, and using naturally replicating cells removes the factor of breaking down like mechanical organs. Popularity for this method should be spread in order to speed the process for full development. This includes research on how to cell print beyond tubular organs. Once this setback is overcome, any organ can be printed specifically for each patient. Thorough examinations must be made to ensure the artificial organ is reasonably comparable to the natural organ in life-span and function. However, once this method is accepted into the medical industry as a viable source for organs rather than donations, many lives can be saved from the transplant waiting list. IV. Acknowledgements Rebustes 9 The Northeastern University Library Resources for access to references in this report, and revisions from Michael Hurtado and Amy Black. Rebustes 10 References [1] (2012). The Need is Real: Data. [Online]. Available: http://organdonor.gov/about/data.html. [2] (2011, February 11). Organ Scaffolding. [Online]. Available: http://www.cloneorgans.com/organ-scaffolding/34/. [3] Markert, Mathias et al. “A Beating Heart Model 3D Printed from Specific Patient,” in 29th Annual International Conference of the IEEE EMBS Cite Internationale, Lyon, France, 2007, pp 4472-4475. [4] Pfister, Andreas et al. “Biofunctional Rapid Prototyping for Tissue-Engineering Applications: 3D Bioplotting versus 3D Printing,” Institut fur Makromolekulare Chemie and Freiburger Materialforschungszentrum, Freiburg, Germany, Jun. 2003. [5] Varghese, David et al. “Advances in tissue engineering: Cell Printing,” in The Journal of Thoracic and Cardiovascular Surgery. Clemson, NC: 2005. pp.470-472. [6] Mertz, Leslie, “From Artificial Kidneys to Artificial Hearts and Beyond,” IEEE Pulse. Pp 1420. May, 2012.