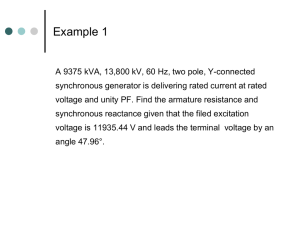

Summer Internship Report - National Power Training Institute (NPTI)

advertisement