list of figures - POLITesi

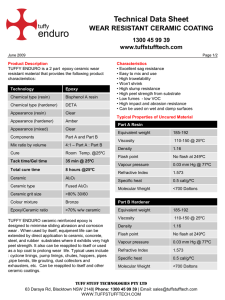

advertisement