Reducing Surgery Time and Improving Patient Outcomes for Eye

Quality Improvement

& Innovation Awards

Written Project

Submission

Entrants Guide

2015

Contents

Overview ................................................................................................................... 3

Key Dates ................................................................................................................. 4

Expression of Interest ............................................................................................... 5

Written Submission ................................................................................................... 6

Assessment Process ................................................................................................. 7

Sample Submission................................................................................................... 8

Supreme Award Winners for 2015

Reducing Surgery Time and Improving Patient

Outcomes for Eye Socket Fractures

Over the period 2012-2014, this project was able to reduce the number of patients returning to theatre after having plates inserted for eye socket fractures. Reducing trauma to the patient, and surgery time and costs.

All right?

All Right? is a public health campaign with the goal of maintaining and increasing the wellbeing of

Cantabrians in the wake of the earthquakes. All

Right? was established in response to international research showing that major natural disasters have negative flow-on affects on people’s health.

All Right? uses the framework of the internationally researched ‘Five Ways to Well

Being’ to provide Cantabrians with the tools and support they need to maintain their mental and

Improved Health and Equity for All Populations physical wellbeing.

Award Winner: All Right?

Runner-up: Under Pressure. CDHB Point Prevalence Pressure Injury Studies

Improved Quality, Safety and Experience of Care

Award Winner: Reducing Surgery Time and Improving Patient Outcomes for Eye Socket

Fractures

Runner-up: Community Alcohol and Drug Service Group programme

Best Value for Public Health System Resources

Award Winner: A Sharper Phlebotomy Service

Runner-up: Optimising Education Provision throughout the South Island

Highly Commended:

Diabetes Coaching, Team Preceptorship, The Health and Wellbeing Connection: Innovation and Collaboration in Action

Consumer Council Award: All Right?

2

Overview

The Canterbury health system Quality Improvement and Innovation Awards were introduced in 2003 to recognise, reward and publicly acknowledge the excellent quality improvements and innovations taking place. The Awards are open to all Canterbury

DHB staff and providers whose services are funded by the Canterbury DHB.

Entering the Awards

Award Winners and Runners-up receive a monetary prize to be used for professional development and resources. To date, 193 initiatives have been entered and several have gone on to receive external recognition by achieving national and international awards.

This document contains information, forms and guidance necessary to submit an initiative into the Awards. Entry consists of three stages:

Completion of the Expression of Interest form, due 24 April 2015

Completion of the Written Submission, due 24 July 2015

Participation in the Assessor Site Visit 7-18 September 2015

The Awards programme is co-ordinated by the Corporate Quality and Patient Safety team. If you have any further queries regarding the awards process or criteria after reading this document, please feel free to contact:

Amanda Bielski, Quality Facilitator,

Corporate Quality and Patient Safety

Internal: 66741

External: (03) 337 7741

Email: amanda.bielski@cdhb.health.nz

Or visit us on the Intranet: http://cdhbintranet/corporate/Quality/SitePages/Home.aspx

3

Key Dates

Date

March 2015

Friday 24 April

May-July

Activity

Canterbury DHB Quality Improvement and Innovation

Awards Open

The 2015 Entrant Materials will be available from early March.

Deadline for submission of Expression of Interest form

All teams planning to complete a submission to the awards must first complete an Expression of Interest form. The Expression of

Interest form is not assessed but will be used to gather preliminary information about the initiative for planning purposes and to match each project team with a Mentor for the duration of the application process.

Mentoring and Submission Preparation

The Submission Guide found in this document promotes a standardised and systematic approach to project management and contains prompts to assist in developing, undertaking and writing-up an initiative.

Friday 24 July

Deadline for submission of completed Templates

Use the Written Project Submission Template to format your submission. The submissions will later be edited and published in a journal to showcase Award entries.

Assessment of Written Submissions August

Site Visits

7-18 September

Following assessment of the written submission, site visits are undertaken to further evaluate the initiatives. Two assessors will complete each site visit to discuss aspects of the content in the written submission, site supporting documentation, and undertake observation if appropriate.

September

Video Profile Filming

Short videos (about 60 seconds in length) will be made to profile each of the initiatives entered. Entrants should contact Medical

Illustration who will schedule a session in September to produce the video profile.

October

2 November

December

Assessor Consensus and Judging

Assessors meet to reach a consensus on the winning initiatives following the site visits. The Judging panel then confirms the overall winners.

Awards Ceremony

Video Profiles are screened and the winners are announced at the

Awards ceremony.

Assessor Feedback Summary distributed

Feedback summaries prepared by the Assessors will be distributed after the awards ceremony. The feedback summary identifies the strengths of the initiative, suggests any opportunities for improvement and provides guidance for future initiatives.

4

Expression of Interest

Completion of the Expression of Interest form is mandatory for all entrants of the 2015

Quality Improvement and Innovation Awards. Expression of Interest forms are available on the Corporate Quality and Patient Safety website and can be submitted anytime until Friday 24 April 2015 .

Email to amanda.bielski@cdhb.health.nz

The information supplied about projects as part of the Expression of Interest stage may also be used to publicise the Awards programme internally and externally throughout the year.

Organisation Name

Division/Service/

Department

Address

Contact

Name

Person

Job Title

Telephone

Which category do you think best fits your project?

Improved quality, safety and experience of care

Improved health and equity for all populations

Best value for public health system resources

(Please note Assessors make the final decision)

Project Title

What are (or were) the timeframes for the project?

Describe your improvement initiative. What was the idea or issue and what did you do? (up to 300 words)

What was the outcome and or impact of your improvement initiative? (up to

300 words)

5

Written Submission Guide

The written submission consists of following sections: Title Page, Information Sheet,

Abstract, Introduction and Background, Planning and Implementation, Results and

Findings, Conclusions and Future Direction, and References.

The Submission Template can be downloaded from the Awards webpage on the

Corporate Quality and Patient Safety website. The template outlines the information that should be included in each section of the submission. It is important that Entrants consider all of the prompts with completing each section, as the Assessors will be using this guide when marking the submissions. The information does not necessarily need to be in the assigned section and should be included in the most appropriate section for the initiative.

In general, when scoring the submission the Assessors will look for evidence that the initiative:

was effectively led and had an overall systematic approach

was well researched and analysed to determine feasibility

had clear objectives that were Specific, Measurable, Achievable, Relevant and

Time-framed (SMART)

was well planned and implemented

was effectively monitored against milestones

had strong, sustainable results that are aligned to the vision and objectives of the initiative

The word limit for the written submission is 3000 words.

Present the initiative as clearly and concisely as possible. Do not include appendices.

Any images, graphs, or documents that are essential to the Assessors’ understanding of the initiative should be included in the body of the submission (see the Sample

Submission for examples of this). The Assessor Site Visit will serve to supplement the information included in the written submission and all other documentation relating to the initiative (e.g. project plan, background and evaluation material) should be made available at the Site Visit.

Please note that the Assessors are a multi-disciplinary group representing a number of different service areas and organisations. Entrants should assume that the reader has no prior knowledge of the service, department or initiative and be careful not to overuse technical terminology and abbreviations. Inclusion of a glossary of terms may be useful.

Please complete the Written Project Submission Template and submit as a Microsoft

Word document no later than Friday 24 July 2015 by

Email to amanda.bielski@cdhb.health.nz

If you do not receive an email within one working day to confirm receipt of your completed written submission, or if you require any further information or assistance please contact Amanda Bielski, Quality Facilitator, Corporate Quality and Patient

Safety, Canterbury DHB on (03) 337 7741, internal extension 66741.

6

Assessment Process

The assessment process consists of three stages: scoring of the written submission, the site visit, and consensus. Assessment of the project is based on the prompts contained in the Submission Template document. These prompts follow a logical sequence that reflects best practice in project management.

Written Submission

Each Assessor reads all of the submissions in one category and provides an overall ranking of the projects. In marking the initiative, the Assessors rely on both the content and completeness of the submission, as well as on clarification and confirmation of information during the site visit.

A scoring matrix is used in conjunction with the prompts in the template, providing the

Assessors with a guide to confirm where within the points range the initiative is placed.

Marks are allocated to each section of the submission as below:

Abstract / Introduction & Background – 5%

Planning & Implementation – 45%

Results / Conclusions & Future Direction – 50%

Site Visit

The site visit takes place after the written submission has been marked, and provides the Assessors an opportunity to meet the project team, observe the initiative in action

(if appropriate) and clarify content in the written submission by gathering more information regarding particular aspects of the initiative. Assessors may also review supporting documentation for the initiative during the site visit.

Consensus & Judging

Assessors work separately to score the initiative against the criteria, but then confer following assessment of the written submission and again after the site visits to reach a consensus on the final scores.

Once the panel of Assessors have agreed on their scores, the marks are presented to the Judging Panel to review the scores and assessment and confirm the award recipients.

Reducing Surgery Time and Improving

Patient Outcomes for Eye Socket Fractures

Submission for the 2014 Canterbury DHB Quality

Improvement and Innovation Awards

Medical Physics and Bioengineering Department

Department of Oral and Maxillofacial Surgery

Eye Socket Fractures Page 2 of 25 2014 CDHB Quality Improvement & Innovation Awards

Table of Contents

Project Information Sheet

.............................................................. 4

Abstract

......................................................................................... 5

Introduction and Background

......................................................... 6

Planning and Implementation

........................................................ 7

Results and Findings

................................................................... 16

Conclusions and Future Direction

................................................ 17

References

.................................................................................. 19

Eye Socket Fractures Page 3 of 25 2014 CDHB Quality Improvement & Innovation Awards

Project Information Sheet

Project title

Reducing Surgery Time and Improving Patient Outcomes for Eye Socket

Fractures

Name and address of service/department

Steven Muir

Medical Physics and Bioengineering Department (MPBE).

2 nd Floor Riverside, Christchurch Hospital, Riccarton Ave, Christchurch.

Chris Lim, Oral & Maxillofacial Department

Contact Person

Name Job Title Email

Steven Muir

Address:

Medical Physicist steven.muir@cdhb.health.nz

Medical Physics and Bioengineering Department (MPBE).

2 nd Floor Riverside, Christchurch Hospital,

Riccarton Ave, Christchurch.

Telephone: 80854

Word Count (limit 3000)

3565 (including literature review and references)

Eye Socket Fractures Page 4 of 25 2014 CDHB Quality Improvement & Innovation Awards

Abstract

Eye socket fractures occur when a blow is received to the eye/cheekbone.

From

2009 to 2013 eye socket fractures have been repaired using commercial titanium plates costing approximately $1000 each. These were inserted at

Christchurch Hospital theatres and a CT scan was performed the following day to verify the correct fit of the plate. Only one surgery could be scheduled for a morning or afternoon session as the plates had to be cut to size and bent to fit the eye socket in theatre, which was time consuming. Plates were often inserted several times into the eye socket before adjustments to the plate shape resulted in an adequate fit. Each attempt results in extra bruising and scar tissue for the patient. After the CT scan, 33 % of cases were found to not fit correctly, resulting in a return to theatre to correct the shape of the plate, which caused further trauma and scar tissue to the patient and further costs for the theatre time.

The aim of this project over the period 2012-2014 was to reduce the number of patients returning to theatre which would reduce trauma to the patient, and reduce surgery time and costs. Three objectives were identified for this project which were:

1. Performing the operations at Burwood Hospital where the O-Arm scanner could verify the correct fit of the plate in theatre before the patient leaves (reducing return to theatre).

2. Producing a low cost 3D plastic model of the eye socket anatomy from a CT scan and using this to pre-shape the titanium plate so it doesn’t require significant modification in theatre (reducing surgery time).

3. Producing titanium plates in the MPBE workshop which cost approximately $26 each, and require less trimming in surgery

(reducing time and cost).

As a result of these changes there have been

1. No return to theatre cases from 31 cases from 2013 to June 2014.

2. The plates usually fit perfectly the first time they are inserted which results in less scar tissue, reduced double vision, and reduced enophthalmos. Time to insert the plate has reduced from an average of

30 minutes to 13 minutes, meaning two surgeries can now be reliably planned for a morning or afternoon session instead of just one.

3. The cost of plates has been reduced dramatically which is good for surgery and when training registrars how to bend the plates. The improved plate design requires less trimming and de-burring which saves time.

Eye Socket Fractures Page 5 of 25 2014 CDHB Quality Improvement & Innovation Awards

Introduction and Background

The health care environment:

The Department of Oral and Maxillofacial Surgery, Christchurch Hospital provides surgery services for jaw and facial bone reconstruction. There are three surgeons responsible for doing the eye socket surgeries and there are approximately 30 eye socket surgeries performed every year in Canterbury.

The three surgeons also train registrars in the techniques.

Medical Physics and Bioengineering provides scientific and technical services for safe, effective, and innovative patient care. There are thirty staff members in the Department. The eye socket fracture work fits well with the MPBE department as it combines medical imaging, bio-modelling and 3D printing to support medical practice.

Motivating or initiating factors:

Poor patient outcomes and high cost of surgery due to the difficulty of shaping the eye plate in theatre and lack of suitable in-theatre imaging, resulting in excessive scarring, a 33% return to theatre rate for revision surgery, and wasted theatre time. The return to theatre rate was calculated from the procedures performed at Christchurch Hospital where no in-theatre imaging was available. Publications on eye socket surgery support Christchurch

Hospital’s return-to-theatre results as a typical rate.

The project team:

MPBE staff: Steven Muir, Nick Cook, Michael Sheedy, Johann Bader, Chris

Morison.

Oral and Maxillofacial Surgery staff: Chris Lim and Jason Erasmus.

Background information

Eye socket or ‘blowout’ fractures occur when a blow is received to the eye/cheekbone. The wall and/or floor of the eye socket is fractured and i ntraorbital material may be pushed out into the paranasal sinuses. Before 2010 fractures were repaired using titanium ‘sugar mesh’ which is supplied as a perforated flat sheet, then cut and bent to shape. It was very difficult to bend in two dimensions and was more suited to small flat defects. From 2010 to 2013, blowout fractures have been repaired using commercial titanium plates costing approximately $1000 each, which were shaped to an average eye socket shape, then cut and bent to fit more accurately during surgery. These were inserted at Christchurch Hospital Theatres and a follow-up CT scan was performed the following day to verify the correct fit of the plate. Only one surgery could be scheduled for a morning or afternoon session as the plates had to be cut to size and bent to shape in theatre, to fit the eye socket , which was time consuming. Plates were often inserted several times into the eye socket before adjustments to the plate shape resulted in an adequate fit. Each attempt results in extra bruising and scar tissue for the patient. After the CT scan the following

Eye Socket Fractures Page 6 of 25 2014 CDHB Quality Improvement & Innovation Awards

day, 33 % of cases were found to not fit correctly, resulting in a return to theatre to correct the shape of the plate, which caused further trauma and scar tissue to the patient and further costs for the theatre time.

Other centres using this initiative

Rapid prototyping of 3D models has been done in other centres for small numbers of patients, but not routinely for every patient. The combination of using pre-formed low cost plates, low cost plastic 3D models for every patient, and in-theatre imaging to verify the fit is unique to this method. Other papers describing the use of 3D models and pre-formed plates are summarised below.

We are the only centre (internationally) to have the combination of using low cost plastic 3D models for every patient, using in-theatre imaging routinely, and producing our own low cost titanium plates.

Planning and Implementation

Summary of Existing Published Research

Two published papers (Hoeltze 2001 and Stuck 2012) describe the benefits of in-theatre CT scans for eye socket surgery, but these were not done in conjunction with 3D models or pre-fitted plates.

Kermer (1998) concluded that stereolithographic models were very useful for m axillofacial surgery planning.

Williams (2009) used an expensive laser sintering machine to produce a model for one patient with sufficient detail to reproduce the floor or the eye socket.

Stereolithographic techniques did not provide adequate resolution.

Kozakiewicz (2006) used inexpensive fused deposition modelling printer to produce models for 6 patients and pre-shape plates and suggested it was an economic way to streamline eye socket surgeries.

Schon (2006) used preformed plates for 19 patients and found that “using preformed implants proved faster, more precise and less invasive, compared to ‘free hand’ efforts, for eye socket injuries using titanium mesh and calvarial grafts.” Followup imaging was performed post-operatively. A more expensive stereo-lithography printing technique was used and the eye socket was mirrored to get the preferred shape.

Metzger (2006) fitted 16 plates into human cadaveric heads and found the use of pre-bent plates improved the accuracy of placement. Plates were bent to an aluminium block that had been milled to shape (not as fine a resolution as fused deposition modelling).

Eye Socket Fractures Page 7 of 25 2014 CDHB Quality Improvement & Innovation Awards

Perry (1998) only made models for particularly complicated patients due to the cost

Site visit

In November 2013 Steven Muir visited Royal Perth Hospital Bioengineering

Workshops to discuss their rapid prototyping techniques. This was very informative and has influenced our capex proposals to purchase an improved printer.

Costings

Costings are given in the Pareto Chart below.

Aim & objectives

The aim of this project over the period 2012-2014 was to reduce the number of patients returning to theatre which would reduce trauma to the patient, reduce surgery time and costs. Three objectives were identified for this project which were:

1. Performing the operations at Burwood Hospital where the O-Arm scanner could verify the correct fit of the plate in theatre before the patient leaves (reducing return to theatre rate & excessive scarring).

2. Producing a low cost 3D plastic model of the eye socket anatomy from a CT scan and using this to pre-adapt the titanium plate so it does not require any significant modification in theatre (reducing surgery time & excessive scarring).

3. Producing titanium plates in the Medical Physics and Bioengineering

Department workshop which cost approximately $26 and require less trimming and deburring (reducing cost). Often offcuts of medical grade titanium (purchased for making larger cranial plates) can be used to further reduce costs.

Planning and approval

The planning and approval process is recorded in the meeting decisions summary, available on site visit.

Feasibility study

Following the literature research, site visits and data review, a fishbone analysis and

Pareto analysis were undertaken to determine feasibility are shown below.

Eye Socket Fractures Page 8 of 25 2014 CDHB Quality Improvement & Innovation Awards

Fishbone Analysis

A fishbone diagram is shown below, showing the causes that lead to high cost and poor patient outcomes for eye socket surgery. The difficulty of shaping a plate in theatre and verifying that it is fitting correctly was noted to be one of the major causes of returns to surgery with the associated poor patient outcomes and higher costs. The expense of obtaining biomodels and plates was also a problem.

Eye Socket Fractures Page 9 of 25 2014 CDHB Quality Improvement & Innovation Awards

35

30

25

20

15

10

5

0

Pareto Analysis

Two Pareto charts are shown, one for detrimental patient outcomes, and one for surgery cost. An average eye socket surgery takes 105 min (average from 2013 data) and based on the ACC theatre rate of $43/min, each surgery costs approximately 105 min x $43/min = $4515. If returns to theatre occur in 33% of cases and results in a further 105 min surgery, this adds an extra cost per patient of 33% x $4515 = $1445.

The time taken to insert the actual plate was on average 30 min, which makes up

$1290 of the total surgery costs. It could be seen that reducing the return to theatre rate would have the biggest impact on improving patient outcomes and reducing costs.

Further gains could be made by reducing the theatre time and reducing the cost of the titanium plates. Detrimental patient outcomes are based on estimations by surgeons as no measurable data exists other than for return to theatre rates.

Pareto analysis - frequency of detrimental patient outcomes

120%

100%

80%

60%

40%

20% return to theatre extended surgery time double vision frequency of occurence 2012 eyelid scar formation enophthalmos

(eye sinking back into socket)

X-Ray radiation dose

Percentage of total frequency

0%

Patreto analysis of eye orbit surgery costs

$1,600 120%

$1,400

$1,200

$1,000

$800

$600

$400

$200

$0 repeat surgeries 32% surgery theatre time for placing plate average 30min titanium plate cost miscellaneous percentage of total imaging cost

100%

80%

60%

40%

20%

0%

Eye Socket Fractures Page 10 of 25 2014 CDHB Quality Improvement & Innovation Awards

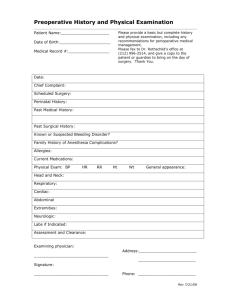

Legal Ethical & Risk Analysis

No legal or ethical issues were identified from team meetings as a result of the changes in practice. A full risk matrix is available on site and the table of surgery risks are shown below with the 2012 risks on the left and the 2014 risks on the right. It can be seen that the high risk items from 2012 (red and orange) have all been reduced to a more acceptable level with the changes in practice implemented.

MPBE Failure Modes and Effects Analysis RD&D 3.2 Appendix B

Process or Product Name:

Started by:

Eye orbit surgery for blowout fracture

Chris Lim

Last updated by: Steven Muir 2014

Key Process Step or Input

Wha t i s the Proces s Step or Input?

Potential Failure Mode

In wha t wa ys ca n the

Proces s Step or Input fa i l ?

Effects of Failure

Effect on the project objecti ves

SEV PROB RISK Potential Causes of Failure

Ri s k s core Wha t ca us es the Key Input to go wrong?

Notes Actions Recommended

Wha t a re the exi s ti ng control s a nd procedures tha t prevent ei ther the Ca us e or

Wha t a re the a cti ons for reduci ng the occurrence of the ca us e, reduci ng the s everi ty of the Fa i l ure Mode?

the ha rm, or i mprovi ng detecti on?

Resp.

Who i s

Res pons i b l e for the recommen ded a cti on?

Actions Taken

Note the a cti ons ta ken. Incl ude da tes of compl eti on.

SEV PROB RISK Further Actions Taken

Ri s k s core Wha t el s e needs to be done? When compl eted: crea te a n a rchi ve copy of thi s s heet a nd upda te new vers i on.

Surgery

Plate Damage during sterilization

Plate no longer suitable to be implanted

Plate becomes sharp/ there are burrs

Plate no longer suitable to be implanted

3

3

Wrong plate used

Plate weakened in theatre

Plate does not fit correctly and requires rebending and reinserting

Patient discomfort/ injured and/or cosmetically affected

5 plate may weaken or crack and become

4 unsuitable before implanting extra scarring to patient

4 plate fit is not correct after surgery and 2nd surgery is required extra scarring to patient, wasted theatre time & expense

5 required plate shape is not available from

Synthes orbit retractor difficult to use surgery cannot proceed slower surgery

4

2

3

3

1

3

4

4

2

4

9

9

5

12

16

20

8

8

Carelessness in transportation or handling

Surgeon cuts or forms plate in theatre more expensive to waste a plate than 2014 make our own cheaper plates

MPBE staff burs more likely as more edge trimming required than 2014 make plates correct size that do not require trimming

None no action taken

MPBE staff designs of plates finalised April

2014 designs of plates finalised April

2014

Multiple plates are taken to theatre and the wrong plate is implanted

Surgeon bends plate too may times more likely as more causing fatigue in material bending is required with no model as a guide no imaging in theatre, no model to pre-bend plate to correct shape, difficulty of seeing if the plate is fitting correctly plates prebent to model so require less bending in theatre

MPBE staff designs of plates finalised April

2014 use in theatre o-arm imaging at Burwood

Hospital and prebend plate

Surgeon models being produced from

2013 with use to model of o-arm incorrectly fitting plate due no imaging in theatre, no model to pre-bend plate to correct shape, difficulty of seeing if the plate is fitting correctly only a limited range of plates available which cover most but not all cases required poor design of retractor use in theatre o-arm imaging at Burwood

Hospital and prebend plate to model

Surgeon models being produced from

2013 with use of o-arm plates can be custom made within MPBE dept to any shape design of retractor beign considered

MPBE staff not yet completed

3

4

5

4

4

4

4

2

1

1

1

1

1

1

1

4

3

4

5

4

4

4

4

8 redesign retractor

Eye Socket Fractures Page 11 of 25 2014 CDHB Quality Improvement & Innovation Awards

Involvement with stakeholders

Team meetings with Maxillofacial and MPBE staff were held as required to develop the processes. A summary of the decisions made at these meetings are available on site if required.

Links to CDHB & National strategic goals

This fits with the Canterbury DHB’s strategic goals of being more peoplecentred, increasing patient safety, and being more effective, efficient, and timely. It also aligns with the national health targets of DHBs living within their means.

Description of innovative aspects of this project

As far as we are aware we are the first project in the world to combine in theatre imaging, routine use of low cost 3D models and, in-house built titanium plates.

These have large potential to reduce surgery time, save costs and improve the patient journey.

Obtaining signoff

Approval to proceed was given by the surgeons after reviewing the accuracy of the 3D models and design of the titanium plates. Sight the summary of meeting decisions for details. Patient permission for the surgery was obtained during pre-surgery consultations by the surgeons. Specific permission to insert MPBE designed plates was not considered necessary as they were of comparable or superior quality to previously accepted techniques.

Key decision dates were:

January 2013 - eye socket surgeries were transferred to Burwood

Hospital for as many cases as possible. First surgery occurred for 8/2/13.

July 2013 - 3D models are verified to be accurate to within 1mm based on Inteleviewer measurements. Approval to produce a 3D model for every eye orbit surgery was granted.

August 2013 design of the standard titanium plate for eye sockets was reviewed, and the approval to produce the plates was granted. The first

MPBE plate was inserted 16/8/13.

April 2014 three other designs of smaller & larger plates were approved.

Eye Socket Fractures Page 12 of 25 2014 CDHB Quality Improvement & Innovation Awards

Implementation of the project

A Gantt chart showing the project timelines is shown below.

Jun-12 Jul-12 Aug-12 Sep-12 Oct-12 Nov-12 Dec-12 Jan-13 Feb-13 Mar-13 Apr-13 May-13 Jun-13 Jul-13 Aug-13 Sep-13 Oct-13 Nov-13 Dec-13 Jan-14 Feb-14 Mar-14 Apr-14 May-14 review costs of eye orbit surgery review return to theatre rate for eye orbit surgeries review surgery location and imaging requirements implement surgery at Burwood using the O-Arm

Investigate 3D modelling options from external providers

Investigate 3D modelling options from MPBE Dept. implement surgery using the Synthes plates prefitted to MPBE model

Develop MPBE protocols and staff training for 3D modelling

Investigate feasibility of manufacturing eyeplates in MPBE

Dept for a standard orbit floor implement MPBE made plates for a standard orbit floor

Investigate plate designs for non-standard orbits and orbit wall defects implement MPBE made plates for non-standard orbits review success of changes

Eye Socket Fractures Page 13 of 25 2014 CDHB Quality Improvement & Innovation Awards

Overview of the implementation process

In-theatre imaging

Two published papers (Hoeltze 2001 and Stuck 2012) clearly describe the benefits of in-theatre CT scans which give accurate 3 dimensional images at an acceptable radiation dose. The arrival of the Medtronics O-Arm portable CT at Burwood Hospital in February 2012 opened up the possibility of verifying the correct placement of the plate while still in theatre. Surgeries were transferred to Burwood in February 2013.

Dose assessments were made which showed the patient would receive no more radiation from in-theatre imaging than they would from a standard follow-up CT scan the day after their operation. Because the O-Arm was not purchased by CDHB and requires less staff to operate, it results in less cost for imaging to the CDHB than running a CT scanner.

Use of 3D models for every patient

Published papers (above) describe how 3D models are extremely useful in improving the accuracy of eye socket surgery. In 2012 - 2013 several trial models were made by a local engineering company, at a cost of approximately $800-$1000 each. However these could only be used for extremely complicated cases due to budget constraints.

Three models were also made at the University of Canterbury but poor quality and difficulty of producing them in a timely manner for clinical work meant it was not feasible for an ongoing service. The purchase of a low cost 3D printer ($1800) by the

MPBE that could produce a model for less than $70 in a few hours, meant that models could be made for every eye socket surgery. After verifying the accuracy of the models, they were routinely produced from July 2013 for pre-fitting plates before surgery.

MPBE made titanium plates

The use of commercially available plates was reviewed in April 2013 and an improved design of plate was developed that did not require trimming for most patients and cost approximately $26 to produce.

Monitoring progress

The spreadsheet of surgery outcomes are available on the site visit which includes surgery time, time spent inserting the plates in surgery and the number of CT scans required in theatre, which indicates how many attempts at re-shaping the plate occur.

Communication processes

Communication for this project has been via face to face meetings. Phone calls and emails. Stakeholders were very enthusiastic about the changes and no resistance to change was encountered.

Documentation and procedure development

14

Maxillofacial staff have staff meetings at which the new techniques are described and new registrars observe more experienced staff for one to three years, developing surgical skills on simpler surgeries, before performing an eye socket surgery themselves.

MPBE staff have developed detailed procedures for the making of the 3D models which are in Medical Implant Procedures (MIP) section 4.12 3D Biomodel Design and

Manufacture. This includes details of using the software to create an accurate 3D model, managing the process of how a surgeon orders a model, how the correct patient data is used to create the model, how to ensure the model is of the correct size, and how to ensure the surgeon gets the correct model for the patient.

MIP 4.13 describes the manufacturing of the titanium plates, including ensuring the titanium is of adequate quality, getting the correct shape and size, surface finishing and making specialised plates for unusual patients/injuries.

MPBE 4.19 describes the record keeping requirements for medical implants.

MPBE processes and procedures are accredited to AS/NZS ISO 9001:2008 “Quality management systems – Requirements” and ISO 13485:2003 “Medical devices –

Quality management systems – Requirements for regulatory purposes”. They are audited internally every two years and externally by Verification NZ every year to ensure they are kept up to date.

15

Results and Findings

The revised Pareto charts show the dramatic improvement in patient outcomes and reductions in surgery costs. It was surprising to surgeons that over the 31 surgeries performed at the time of writing, there have been none that required a return to theatre.

This has exceeded expectations about the success of the project. Ongoing savings in theatre time for inserting the plate are likely to be greater than those shown in the graph, which include surgeries where surgeons were unfamiliar with the new theatre, plates and models and so took more time. The most recent surgeries often take only four minutes to insert the plate (compared to 13 minute average for the new technique, and 30 minute average for the old technique)

35

30

25

20

15

10

5

0

Pareto analysis - frequency of detrimental patient outcomes

40%

20% return to theatre extended surgery time double vision eyelid scar formation enophthalmos

(eye sinking back into

X-Ray radiation dose socket) frequency of occurence 2012

Percentage of total frequency frequency of occurence 2014

0%

120%

100%

80%

60%

16

Patreto analysis of eye orbit surgery costs

120% $1,400

$1,200

$1,000

$800

$600

$400

$200

100%

80%

60%

40%

20%

$0 0% surgery theatre time for placing plate, reduced from 30min to titanium plate cost

13min @ $43/min (ACC rate) cost of eye orbit surgery 2012 repeat surgeries reduced from

20% to 0% cost of eye orbit surgery 2014 miscellaneous percentage of total imaging cost

There are approximately 30-35 blowout fracture operations performed every year, resulting in savings of at least:

Reduced surgery time: 30 x $731 = $21,930

Repeat surgeries: 10 x $4515 = $45,150

In-house titanium plates: 30x$1,000 = $30,000

Total = $97,080 per year.

Conclusions and Future Direction

Overall evaluation of the project

The review of eye socket surgery procedures has been extremely effective in reducing the number of returns to theatre from 33% to zero, resulting in less scarring to the patient, faster treatment time, and has doubled the number of procedures that can be performed in a morning or afternoon operating session. There have also been huge cost savings by reducing theatre time and return to theatres, as well as by manufacturing the plates in the MPBE department.

Ongoing monitoring activities

Statistics for operating times, number of CT scans performed in theatre, and returns to theatre will continue to be measured to ensure the method continues to work effectively.

17

Future directions

The benefits of 3D models for surgery planning could be extended to other departments, and this will be explored over the next year. The design of commercially available eye orbit retractor tool was highlighted as one of the risks in the surgery risk analysis process. An improved design made by MPBE staff is planned for development from late 2014-2015.

Communication of knowledge

Chris Lim is submitting a paper to the Craniomaxillofacial Trauma and Reconstruction journal and presenting it at the Australian & New Zealand Association of Oral and Maxillofacial

Surgeons conference in Auckland (October 2014). This will provide opportunities to discuss how these improved techniques could be used throughout New Zealand.

Michael Sheedy (MPBE Dept.) is presenting a paper at the Australian Biomedical

Engineering Conference (ABEC) 2014 20 - 22 August 2014 in Canberra. A low cost process for creating 3D bio-models for use in reconstruction of orbital fractures. Michael is also planning to submit a technical note in the ACPSEM journal.

Retention of Knowledge

The knowledge gained from this project is documented within the MPBE quality system procedures, and in Oral & Maxillofacial Department protocols to ensure new staff are familiar with the processes.

Recognition strategies

Proposed article in CDHB News. Innovation award application.

18

References

Hoelzle F, Klein M, Schwerdtner O (2001) Intraoperative computed tomography with the mobile CT Tomoscan M during surgical treatment of orbital fractures Int. J. Oral Maxillofac.

Surg. 2001; 30: 26 –31 doi:10.1054/ijom.2000.0014

Kermer C, Lindner A, Friede I (1998) Preoperative stereolithographic model planning for primary reconstruction in craniomaxillofacial trauma surgery. J Craniomaxillofac Surg

1998;26:136 –9.

Kozakiewicz M, Ski P K and Broniarczyk-Loba A. (2009) Clinical application of 3D pre-bent titanium implants for orbital floor fractures. Journal of Cranio-Maxillofacial Surgery, 37,

229e234 European Association for Cranio-Maxillofacial Surgery doi:10.1016/j.jcms.2008.11.009.

Metzger M C, and Gellrich N. (2006) Anatomical 3-dimensional Pre-bent Titanium Implant for

Orbital Floor Fractures , Ophthalmology 2006; 113:1863 –1868 © 2006 by the American

Academy of Ophthalmology.

Metzger MC, Schon R, Schulze D, Carvalho C, Gutwald R, Schmelzeisen R (2006)

Individual preformed titanium meshes for orbital fractures. Oral Surg Oral Med Oral Pathol

2006: 102: 442

–447.

Perry M, Banks P, Richards R (1998) The use of computer generated three-dimensional models in orbital reconstruction. Br J Oral Maxillofac Surg 1998;36:275 – 84.

Schon R, Metzger M C, Zizelmann C, Weyer N, Schmelzeisen R (2006) Individually preformed titanium mesh implants for a true-to-original repair of orbital fractures. Int. J. Oral

Maxillofac. Surg. 2006; 35: 990 –995. # 2006 Published by Elsevier Ltd on behalf of

International Association of Oral and Maxillofacial Surgeons.

Stuck BA , Hu R (2012) Intraoperative cone beam computed tomography in the management of facial fractures. Int. J. Oral Maxillofac. Surg. 2012; 41: 1171 –1175. http://dx.doi.org/10.1016/j.ijom.2012.06.006

,

Williams J. V. and Revington P. J. (2009) Novel use of an aerospace selective laser sintering machine for rapid prototyping of an orbital blowout fracture. Int. J. Oral Maxillofac.

Surg. 2010; 39: 182 –184. #2009 International Association of Oral and Maxillofacial

Surgeons. Published by Elsevier Ltd.

19