Peroxide-forming chemicals - Environmental Health & Safety

advertisement

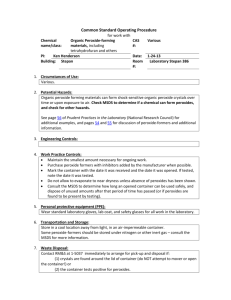

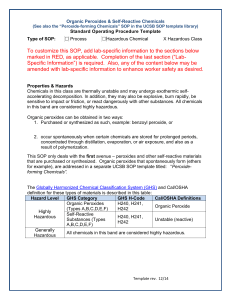

PEROXIDE-FORMING CHEMICALS STANDARD OPERATING PROCEDURE TEMPLATE (see also these related SOPs in the UCSB SOP Library: “Flammable Liquids”, “Solvent Use: Extractions, Distillations and Still Quenching” ) Type of SOP: Process Hazardous Chemical Hazard Class To customize this SOP, add lab-specific information to the sections below marked in RED, as applicable. Completion of the last section (“Lab-Specific Information”) is required. Also, any of the content below may be amended with lab-specific information to enhance worker safety as desired. 1. HAZARD OVERVIEW Organic peroxides are among the most hazardous substances handled in the chemical laboratory. They are generally low-power explosives that are sensitive to shock, sparks, or other accidental ignition. They are far more shock-sensitive than most primary explosives such as TNT. Organic peroxides can be obtained in two ways: 1. purchased as such, e.g. benzoyl peroxide, or 2. occur spontaneously when certain chemicals (see below) are stored for prolonged periods, concentrated through distillation, evaporation, or air exposure, and also as a result of polymerization. This SOP only deals with the second avenue – peroxides that can form in the lab. Organic peroxides that are purchased are addressed in a separate UCSB SOP template titled: Organic Peroxides and Self-Reactive Chemicals. Organic peroxides are organic compounds containing the peroxide functional group (R-O-OR'), where R = an organic group. These materials are sensitive to oxygen, heat, friction, impact, light, and strong oxidizing and reducing agents. Peroxide forming chemicals are compounds that undergo auto-oxidation to form organic hydroperoxides and/or peroxides when exposed to the oxygen in air. Especially dangerous are ether bottles that have evaporated to dryness. A peroxide present as a contaminant in a reagent or solvent can be very hazardous and can change the course of a planned reaction. Auto-oxidation of organic materials (solvents and other liquids are most frequently of primary concern) proceeds by a free-radical chain mechanism. For the substrate R—H, the chain is initiated by ultraviolet light. The unusual stability problems of this class of compounds make them a serious fire and explosion hazard that requires careful management. Template rev. 11/14 2. HAZARDOUS CHEMICALS/CLASS OF HAZARDOUS CHEMICALS The following are examples of specific compounds that are prone to forming peroxides: Acetal Butadiene Cumene Cyclohexene Cyclooctene Decahydronaphthalene Decalin Diacetylene Dicyclopentadiene Diethylene glycol Diisopropyl ether Dioxane Dimethyl ether Divinyl acetylene Ethyl ether Ethylene glycol dimethyl ether Isopropyl ether Methyl acetylene Methylcyclopentane Potassium metal Sodium amide Styrene Tetrahydrofuran Tetrahydronaphthalene Tetralin Vinyl acetate Vinyl actylene Vinyl chloride Vinyl ethers Vinylidene chloride Most of the above specific examples fall into these chemical structure types: 3. Ethers, especially cyclic ethers and those containing primary and secondary alkyl groups (never distill an ether before it has been shown to be free of peroxide) Aldehydes Compounds containing benzylic hydrogen Compounds containing allylic hydrogens (C=C-H), including most alkenes; vinyl, and vinylidene compounds Compounds containing a tertiary C-H group (e.g., decalin and 2,5-dimethyl hexane) PERSONAL PROTECTIVE EQUIPMENT (PPE) See the PPE information under Sec. II of the UCSB Chemical Hygiene Plan regarding: 4. the UC PPE Policy and policy summary (what PPE is needed and when/where to use) obtaining your PPE via use of the Laboratory Hazard Assessment Tool glove selection criteria respirator use, etc. ENGINEERING/VENTILATION CONTROLS 1. Use at least one of the following engineering controls: a. Fume hood: Work inside a certified chemical fume hood at all times. b. Glove box: When inert or dry atmospheres are required. c. Portable explosion shield: May also be required to control the risk of explosion. d. Gas cabinet: If the material is classified as a compressed gas. 2. Use bonding and grounding equipment to minimizing the likelihood of an ignition from static electricity during the transfer of all Class I flammable liquids – see the Flammable Liquids SOP template in the UCSB SOP library. 2 3. Know where your safety equipment is located (i.e., fire extinguisher, eye wash/safety shower, and first aid kit). 4. Have the appropriate fire extinguisher available. For further information see the following pages in Sec. II of the UCSB Chemical Hygiene Plan: Fume Hood Usage Guide Criteria for Implementing Engineering Controls 5. SPECIAL HANDLING PROCEDURES AND STORAGE REQUIREMENTS 1. At least one other person should be present in the same laboratory, or nearby, when any work involving peroxide forming chemicals is carried out. 2. Eliminate or substitute a less hazardous material when possible. 3. Design your experiment to use the smallest amount of material possible to achieve the desired result. 4. Verify your experimental set-up and procedure prior to use. 5. Ensure all equipment is appropriate for the task. 6. Avoid inadvertent incompatibles: a. Heat sources, open flames and oxidizers b. Consult with the campus Chemical Hygiene Officer if work involves large quantities. 7. Conduct distillation, extraction or crystallization, and other processes that concentrate the organic peroxides only when it is explicitly known safe to do so. Diethyl ether must be used in a fume hood. THF-containing mobile phase must be prepared in the fume hood but may be used outside of the fume hood on HPLC equipment so long as the mobile phase supply container is covered. Refrigeration of diethyl ether is not recommended. Reduced temperature can impede the peroxide-scavenging ability of added preservatives and may actually increase peroxide formation. Reduced temperature may also decrease the solubility of any solid peroxides that have formed, thereby increasing the hazard. STORAGE: 1. Purchase and use the minimum amount of material necessary to perform your research. 2. Label peroxide-forming materials clearly and promptly with the date upon receipt or synthesis. Dispose of old materials when past their expiration date. For many ethers this is usually in the 6 to 12 months range. 3. The presence of peroxides in some cases is indicated by the appearance of a precipitate or oily layer in the container. 4. Store all peroxide forming materials inside of a flammable cabinet 5. Review your inventory frequently to prevent peroxide-forming chemicals from becoming unsafe. 6. Test materials for peroxide formation before using, particularly if the materials is to be concentrated via distillation/evaporation. See test methods below. 7. Do not handle old or expired peroxide-forming materials that are discovered. Inform your Principal Investigator immediately and dispose of the item as a hazardous waste. 8. Ether solvents: Ether solvents stored in solvent drying cartridge manifolds can be excluded since these are kept air-free under a positive pressure of inert gas. The dangers associated with ether solvents depend on and can be exacerbated by these factors: a. Exposure to air (oxygen) 3 b. c. d. e. f. g. h. i. Exposure to light Temperature Friction Shock Concentration Chemical structure Distillation that removes stabilizers Slow evaporation of volatile ethers over time j. Impurities Peroxide Detection Tests From Prudent Practices in the Laboratory: Handling and Management of Chemical Hazards, 2011. Sec. 6.G.3.2: The following tests will detect most (but not all) peroxy compounds and all hyperperoxides. Results of peroxide detection tests must be indicated on the container/tag with test date, test results/method, and initials of the authorized person conducting the test. NOTE: These tests should not be used for testing materials potentially contaminated with inorganic peroxides (i.e., potassium). Option 1. Add 1-3 ml of the liquid to be tested to an equal volume of acetic acid, add a few drops of 5% potassium iodide (KI) solution and shake. The appearance of a yellow to brown color indicates the presence of peroxides. Option 2. Addition of 1 ml of a freshly prepared 10% KI and 10 ml of an organic solution in a 25 ml glass cylinder should produce a yellow color if peroxides are present. Option 3. Add 0.5 ml of the liquid to be tested to a mixture of 1 ml of 10% KI solution and 0.5 ml of dilute hydrochloric acid to which a few drops of starch solution have been added just before the test. The presence of a blue-black color within a minute indicates the presence of peroxides. Option 4. Peroxide test strips that turn an indicative color in the presence of peroxides. Take care to follow manufacturer instructions for effective detection. In general, the strips must be air dried until the solvent evaporates and then exposed to moisture for proper operation. 6. SPILL AND INCIDENT PROCEDURES See directions under the “Chemical Incident” and “Medical Emergency” tabs of the UCSB Emergency Information Flipchart – should already be posted in all labs. 4 7. DECONTAMINATION If there are incidental drips of peroxidizable solvent on the fume hood work surface, secure ignition sources and lower the sash to allow for evaporation. If bench paper becomes contaminated, it must be removed, replaced and disposed of as hazardous waste. 8. WASTE DISPOSAL See “Chemical Waste Disposal” in Sec. II of the UCSB Chemical Hygiene Plan. If you suspect a material is peroxidized, let the EH&S waste disposal personnel know this. 9. PRIOR APPROVAL/REVIEW REQUIRED As they deem necessary, the PI/supervisor should insert here any prior approval or review needed before an individual can do the operation. The Principal Investigator must be notified and approval must be obtained if diethyl ether will be heated above room temperature or if the solvent volume will be reduced under reduced pressure (rotary evaporation technique). This is a very hazardous process, and concentration of the diethyl ether could cause crystals of potentially explosive ethereal peroxides to form. Consult with the Principal Investigator for alternative methods for reducing solvent volume. 10. DESIGNATED AREA As they deem necessary, the PI/supervisor should insert here any information about whether a special use-area is designated for this material/process. Work should be completed in a laboratory fume hood. 11. SAFETY DATA SHEETS Found online at: http://ehs.ucsb.edu/labsafety/msds Review R.J. Kelly’s paper Review of Safety Guidelines for Peroxidizable Organic Chemicals (Journal of Chemical Health and Safety; Sept/Oct 1996). 12. LAB-SPECIFIC INFORMATION (required) (Examples of appropriate content) Add appropriate lab-specific information here describing how this material(s) is generally used. E.g., name of protocol, typical frequency done, quantities used, temperature and any additional safety measures, etc. 5

![AL Chem Written Practical (Organic Chemistry) [F.7]](http://s2.studylib.net/store/data/005797652_1-4911d95dd6c8a0840f727bd387aa6027-300x300.png)