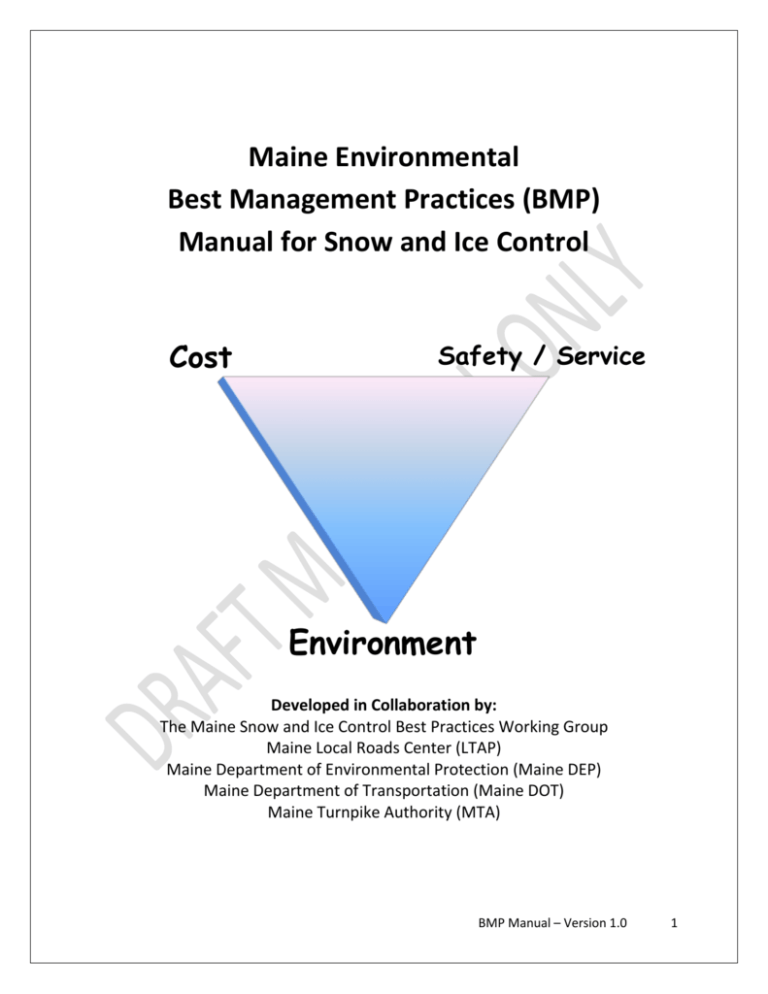

What is the cost to implement?

advertisement