Corrosives

advertisement

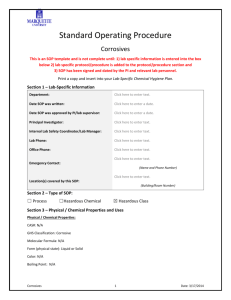

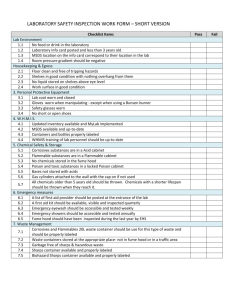

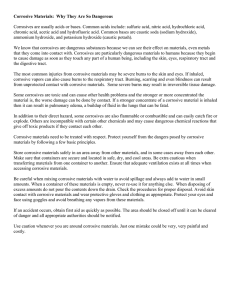

STANDARD OPERATING PROCEDURE Procedure: School/Department: SOP prepared by: Working with Corrosives School of Biological Sciences Dianne Fisher and Nick Coleman (SMB), edit M Joseph Section 1 - Personal Protective Equipment 1. Safety Glasses or goggles (face shield if handling large quantities) 2. Lab coat or lab gown (coat is preferable– thicker & more protective) with full length heavy plastic apron. 3. Gloves (preferably nitrile, or thick butyl gloves if handling large quantities) 4. Fully enclosed shoes (preferably leather) with non-slip soles 5. Respirator if required (eg. if fuming nitric acid has to be handled outside a fume hood) Section 2 – Potential Hazards + Safety precautions 1. Contact/Absorption – corrosive liquids have high potential to cause serious burns and irritation to skin and eyes 2. Inhalation – corrosive gases/vapour can damage lining of the lungs 3. Ingestion – severe irritation (nausea, vomiting and diarrhoea) and permanent damage to gastrointestinal tract 4. Other hazards – may react with other substances and generate/evolve heat Section 3 – Procedure 1. Obtain and read MSDS for each corrosive to be handled 2. Know the location of spill kits, eyewashes, safety showers, fire extinguishers and fire blankets before starting work. 3. Wear PPE, especially eye protection. 4. Larger volumes (>10 ml) of strong corrosive liquids should be handled in a fume hood, as these may generate corrosive vapours. (see SOP/risk assessment for fume hood) Other less-powerful corrosive substances or small volumes should be used in well-ventilated areas. 5. Use heat-resistant glassware because heat may be generated when corrosives are mixed with other liquids. 6. For diluting strong acids, always add acid to water (dropwise or slowly) 7. Wipe up any spills on the outside of the container after use 8. Wash hands promptly after using corrosives Section 4 – Spill Procedure and Waste Disposal 1. Consult MSDS of specific chemical for spill procedure 2. Keep an appropriate spill kit and appropriate PPE in lab and be informed how to use them (ensure you are properly trained) 3. Corrosive liquids – apply a neutralising agent (e.g. place sodium bicarbonate on acid spills, 2% hydrochloric on caustic/basic spills) and water as necessary. Test pH with pH strips and ensure final pH is 6 – 10. Once neutralised, absorb with paper towel. Place paper towel in labelled plastic bag (eg. label ‘Nitric acid spill waste – neutralised’), then leave bag open in fume hood overnight to allow any residual vapours to disperse. Seal bag, and dispose of as hazardous chemical waste (See SOP/risk assessment for chemical waste) Issue date: 20/11/12 Review date: 20/11/13 Page 1 of 3 4. Corrosive solids – solids of low toxicity can be swept onto dust pan and deposited into plastic bag (wipe dust pan clean). Label the bag, and dispose of as hazardous chemical waste. Section 5 – First Aid 1. First aid – Consult MSDS of specific chemical for treatment advice 2. Eye/Skin contact – use emergency eye wash/shower and flush affected area on body (remove any jewellery) with copious amounts of water for at least 15 mins (do not use neutralising substances on affected areas). Seek medical advice. 3. Inhalation – Move exposed person to well ventilated area if safe to do so. Seek immediate medical advice. 4. Ingestion – Seek immediate medical advice. 5. Any injuries, incidents or near misses (dangerous situations not resulting in an incident) must be reported to your supervisor and via the online reporting system Section 6 – Storage and transport 1. Store acids separately from bases where possible (check MSDS information) 2. Store in cool, dry, well-ventilated areas, away from sunlight 3. Acids should be stored in a dedicated Corrosives cabinet (preferably non-metal as cabinets will corrode over time) 4. If dedicated corrosives storage is unavailable, store corrosive liquid containers in a secondary containment (e.g. high density polyethylene tub) with a combined volume 10% greater than stored containers 5. Carry large bottles of corrosives in a proper Winchester carry-all and take care when carrying them around lab Section 7 – Relevant Material safety data sheets and references Consult MSDS of specific chemical. ChemAlertII http://chemalert.ucc.usyd.edu.au/chemalert/index/index.do See also risk assessment “Corrosives”, and risk assessment and SOP “Disposal of chemical waste” Working with Chemicals http://sydney.edu.au/whs/guidelines/chemical/hazsubs1.shtml Issue date: 20/11/12 Review date: 20/11/13 Page 2 of 3 SOP Training Confirmation By signing below, these individuals confirm that they have read and understood the SOP, and agree to always follow the instructions in this SOP when performing this procedure. Position Name Signature Date Supervisor employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student WHS Committee Approval Representative: A. Prof Frank Seebacher Chair Safety Committee Signature: ........................................................ Date: ..................................... Issue date: 20/11/12 Review date: 20/11/13 Page 3 of 3

![[Download MSDS] (.doc)](http://s3.studylib.net/store/data/006712111_1-6d2aee48fdad537db5a64f921a9ed630-300x300.png)