October 16, 2007

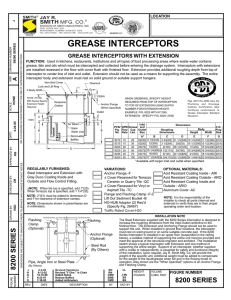

advertisement

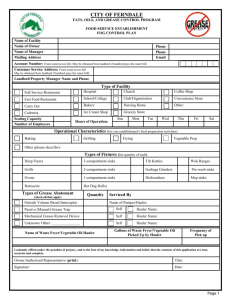

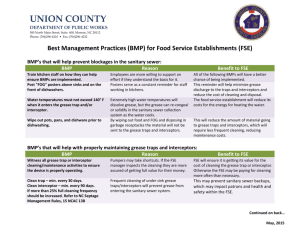

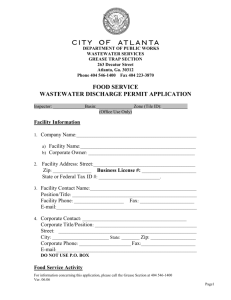

Public Works Department Environmental Division Industrial Pretreatment Program Meridian City Hall, Suite 204 33 E Broadway Avenue Meridian, Idaho 83642 Wastewater Pretreatment Requirements The intent of the pretreatment plan review process is to determine if additional pretreatment of discharged wastewater is required prior to the construction or discharge of wastewater of a new building and tenant improvements. City Standard for New Grease Interceptor Construction The present approved City of Meridian standard is a 1500 gallon capacity (minimum), double chamber in-ground vault. Grease interceptor shall be located outside of building in a location accessible to waste hauler pumper. To decrease internal vault decomposition, it is recommended to apply a protective coating. The primary and secondary chamber outlet & inlet pipes must have tee connections with open pipe tops to allow visual inspections of influent and effluent (wastewater) by City inspectors. Tee pipe length is 12-14 inches from the tank bottom, center baffle cross over tee pipe is usually recommended as per grease interceptor manufacturers’ design. Chamber lids must prevent odors with a built in handle or notched side to insert a tool to allow easy access for lid removal. Temporary sealant type material is only allowed in lid holes to eliminate odors; bolts to secure lids in place are not recommended. Each user for which a grease interceptor is required shall, in the discretion of the superintendent or designee: (1) Install and/or use a grease interceptor which shall serve only that user, or (2) Enter into a written agreement or permit with the City of Meridian establishing comparable best management practices. Installation of a Sample Station Port is optional and is not required. Approved Exception to the In Ground Grease Interceptor A suitable portable unit with specific specifications may be approved on a very limited basis. An Electro-Mechanical Unit or Automatic Grease Interceptor (AGI) may be installed to the facilities clean up sink. This unit must be of the type designed to mechanically remove fats, oils and grease (FOG) automatically. Unit must have a timer device to activate contained grease discharge in a separate container for proper disposal. Passive grease traps are not allowed in a new or remodeled construction activity. Public Works Department – Environmental Division 33 E. Broadway Avenue, Meridian, ID 83642 Phone 208-898-5500 Fax 208-898-9551 www.meridiancity.org Page 2 Typical Example of In-Ground Grease Interceptor Oil and Flammable Liquids Interceptor. As required by the Uniform Plumbing Code 1017.1: “All repair garages and gasoline stations with grease racks or grease pits, and all factories that have oily, flammable, or both types of waste as a result of manufacturing, storage, maintenance, repair, or testing processes, shall be provided with an oil or flammable liquid interceptor that shall be connected to all necessary floor drains.” Page 3 Typical Example of an In-Ground Flammable Liquids Interceptor Discharge Requirements for Elevator Pit Drain and Sump Pump On December 7, 2010 the State of Idaho, Division of Building Safety issued a Policy statement that the sump pump (or drain) required in elevator pits by ASME A17.1 Section 2.2.2.5 will now be considered optional rather than mandatory. In the case of hydraulic elevators, if a sump pump is installed, the City of Meridian requires the drain and pump combination be connected to an oil/water separator prior to discharge to the City’s sanitary sewer system. It is recommended a professional engineering analysis of the elevator’s liquid hydraulic and fire suppression evacuation requirements be conducted, in order to specify an adequately-sized sump pump and interceptor system to retain and prevent oils from entertaining the sanitary sewer system.