VEHICULAR SHAFT FOR POWER TRANSMISSION DESIGN

advertisement

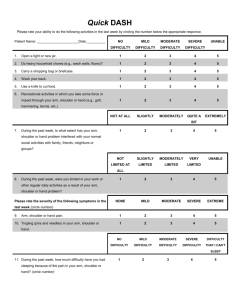

VEHICULAR SHAFT FOR POWER TRANSMISSION DESIGN PROJECT MEC 410: Design of Machine Elements Kanchan Bhattacharyya Jackie Chen Matthew Stevens Han John Tse Known Information: 1. Purpose: Power Transmission w/ Diff. Speed Ratios 2. Shaft Material: Stainless Steels (Many Types) 3. Known Dimensions: Figure 1. Initial Design Sketch With Proposed Dimensions 4. Rotational load is considered sinusoidal with cyclic dynamic loading 5. Peak load 10,000 N @ frequency = 100 Hz, Design Safety Factor = 3.0 Design Objectives: 1. Determining Endurance Limit 2. Stress Concentration Reduction (With FEA Visualizations) 3. Machine Keyway Width & Height Selection 4. Final CAD Drawing 1 I. Determining Endurance Limit: Endurance Limit Considerations a. Considering AISI 304 Stainless Steel with 𝑆𝑢𝑡 = 73.2 𝑘𝑝𝑠𝑖 (choice pre-determined from fillet radii calculations in section III.) The Rotary-Beam Endurance Limit: 𝑆𝑒′ = 0.5𝑆𝑢𝑡 = 36.6 𝑘𝑝𝑠𝑖 Considering Modification Factors; Surface Factor: 𝑘𝑎 = 𝑎𝑆𝑢𝑡 𝑏 considering a machined surface; 𝑎 = 2.70, 𝑏 = −0.265 Then 𝑘𝑎 = (2.70)(73.2 𝑘𝑝𝑠𝑖)−0.265 = 0.8655 Size Factor: Consider diameter d = 0.2m = 7.87 in; 𝑘𝑏 = 0.91𝑑−0.157 = 0.658 *Note that the main diameter is d (the one with the key-way) Loading Factor: For combined bending and torsion experienced by the shaft, we let 𝑘𝑐 = 1 Temperature Factor: Neglecting extreme temperature conditions, let 𝑘𝑑 = 1 Reliability Factor: Assume a relatively high degree of reliability, and a reliability goal of 99%, 𝑘𝑒 = 0.814 Miscellaneous Factors: Assume 𝑘𝑒 = 1 Then, the endurance limit at the critical locations becomes 𝑆𝑒 = 𝑘𝑎 𝑘𝑏 𝑘𝑐 𝑘𝑑 𝑘𝑒 𝑘𝑓 𝑆𝑒 ′ = (0.8655)(0.658)(1)(1)(0.814)(1)(36.6) = 𝟏𝟔. 𝟗𝟔 𝒌𝒑𝒔𝒊 2 II. Stress Concentration Reduction A. Where are the highest stresses present? (Analytical) Figure 2. Main Shaft Diameter w/ Keyway FBD: Given: 𝑃𝑒𝑎𝑘 𝑇𝑟𝑎𝑛𝑠𝑚𝑖𝑡𝑡𝑒𝑑 𝐿𝑜𝑎𝑑 𝐹𝑇 = 10,000 𝑁 Solving for Reaction Forces: 𝐹𝑇 𝐹𝑅 = = 10,641.78 𝑁 cos(20°) 𝐹𝑁 = sin(𝐹𝑅 ) = 3,639.7 𝑁 𝐹𝑁 𝑅𝑒𝑎𝑐𝑡𝑖𝑜𝑛 𝐹𝑜𝑟𝑐𝑒𝑠 𝑖𝑛 𝑥𝑦 𝑝𝑙𝑎𝑛𝑒 = = 1819.85 𝑁 2 𝐹 𝑅𝑒𝑎𝑐𝑡𝑖𝑜𝑛 𝐹𝑜𝑟𝑐𝑒𝑠 𝑖𝑛 𝑥𝑧 𝑝𝑙𝑎𝑛𝑒 = 𝑇 = 5,000 𝑁 2 *Note: Middle of Bearing O taken as “zero” for XY Plot; Range of Plots are from Bearing to Bearing. Figure 3. XY Plane FBD: Figure 4. XY Plane Shear Diagram: Figure 5. XY Plane Bending Moment Diagram: XY Shear: 0 ≤ 𝑥 ≤ 0. 45 𝑚 → 𝑉 = 1819.85 𝑁 0.45 𝑚 < 𝑥 ≤ 0.90 𝑚 → 𝑉 = −1819.85 𝑁 XY Bending: (“Key” M values @ middle of shaft segments) 𝐵𝑒𝑎𝑟𝑖𝑛𝑔 𝑂: 𝑥 = 0. 05 𝑚 → 𝑀 = 90.9975 𝑁 𝑚 𝐿𝑒𝑓𝑡/𝑅𝑖𝑔ℎ𝑡 𝑆ℎ𝑎𝑓𝑡: 𝑥 = 0.215; 0.685 𝑚 → 𝑀 = 454.9625 𝑁 𝑚 𝑪𝒆𝒏𝒕𝒆𝒓 𝑺𝒉𝒂𝒇𝒕: 𝒙 = 𝟎. 𝟒𝟓 𝒎 → 𝑴 = 𝟖𝟏𝟖. 𝟖𝟗 𝑵 𝒎 𝑅𝑖𝑔ℎ𝑡 𝑆ℎ𝑎𝑓𝑡: 𝑥 = 0.685 𝑚 → 𝑀 = 454.9625 𝑁 𝑚 3 Figure 6. XZ Plane FBD: Figure 7. XZ Plane Shear Diagram: Figure 8. XZ Plane Bending Moment Diagram: XY Shear: 0 ≤ 𝑥 ≤ 0. 45 𝑚 → 𝑉 = 5,000 𝑁 XY Bending: 0.45 𝑚 < 𝑥 ≤ 0.90 𝑚 → 𝑉 = −5,000 𝑁 𝐵𝑒𝑎𝑟𝑖𝑛𝑔 𝑂: 𝑥 = 0. 05 𝑚 → 𝑀 = 250 𝑁 𝑚 𝐿𝑒𝑓𝑡/𝑅𝑖𝑔ℎ𝑡𝑆ℎ𝑎𝑓𝑡: 𝑥 = 0.250; 0.650 𝑚 → 𝑀 = 1250 𝑁 𝑚 𝑪𝒆𝒏𝒕𝒆𝒓 𝑺𝒉𝒂𝒇𝒕: 𝒙 = 𝟎. 𝟒𝟓 𝒎 → 𝑴 = 𝟐𝟐𝟓𝟎 𝑵 𝒎 Stress Calculations: Stresses can be calculated using moments from critical points found in the shear-moment diagrams and these relations: 𝑀𝑐 𝜋𝑑 4 𝜎𝑎 = ;𝐼= ;𝜎 = 0 𝐼 64 𝑚 𝑇𝑟 𝜋𝑑4 𝜏𝑚 = ;𝐽= ; 𝜏𝑎 = 0 𝐽 32 XY PLANE NORMAL STRESSES: (AT EACH SHOULDER FROM LEFT TO RIGHT) 𝜎1 = 7,414,735.9 𝑃𝑎 𝜎2 = 4,634,201.0 𝑃𝑎 𝜎3 = 1,042,694.1 𝑃𝑎 XZ PLANE NORMAL STRESSES: (AT EACH SHOULDER FROM LEFT TO RIGHT) 𝜎1 = 20,371,832.7 𝑃𝑎 𝜎2 = 12,737,395.5 𝑃𝑎 𝜎3 = 2,864,789.0 𝑃𝑎 The resultant stress at shoulder 1 is clearly going to be largest: 𝜎𝑠 = 𝜎1 2 + 𝜎2 2 𝝈𝒔𝟏 = 𝟐𝟏, 𝟔𝟕𝟗, 𝟐𝟓𝟎 𝑷𝒂 SHEAR STRESSES: Shoulder 1: 𝝉𝒔𝟏 = 𝟐𝟎, 𝟑𝟕𝟏, 𝟖𝟑𝟑 𝑷𝒂 Shoulder 2: 𝜏𝑠2 = 2,546,479 𝑃𝑎 REVISITING Q: Where are the highest stresses present? ANSWER: Local stress maximums at shoulders 1, 2, and 3, with the highest absolute stresses at shoulder 1 with 𝝈𝒔𝟏 = 𝟐𝟏, 𝟔𝟕𝟗, 𝟐𝟓𝟎 𝑷𝒂 and 𝜏𝑠1 = 𝟐𝟎, 𝟑𝟕𝟏, 𝟖𝟑𝟑 𝑷𝒂. 4 B. Where are the highest stresses? (FEA Visualization) Figure 9. Snapshots of FEA simulations shown prior to shoulder modification via fillets to reduce stress concentrations; Top Left shows displacement in mm; Top Right shows strain in mm/mm; Bottom Center shows Von Mises Stresses in MPa. General color coding scheme is blue sky blue green yellow red from lowest to highest values for given quantities. - - - - Note that transition from bearing to left shaft at Shoulder 1 and from left shaft to center shaft at Shoulder 2 both exhibit a transition from the sky blue to a localized green in both strain and vonmises stresses. For the displacement, it happens to be a blue to green transition for Shoulder 1 and a yellow to orange transition for Shoulder 2. The actual colors are magnitude dependent but the important thing to notice is that it can be visually confirmed that the shoulders bear the most localized stress while stresses within shaft segments are relatively uniform. These shoulders therefore become the main area to reduce stress concentrations. C. Choosing Fillet Radii for Shoulder 1 (between bearing and left shaft) and Shoulder 2 (between left and center shaft) to reduce stress concentrations: Fillet radii can either be determined by choosing a material and using its yield strength to calculate fillet radii or picking the fillet radii and checking against material strengths (in this case among stainless steels) to pick the steel. o This latter option was chosen. Equations for Comparison: (1) Von-Mises Maximum Stress: (Under steady conditions) 𝜎 ′ 𝑚𝑎𝑥 = [(𝜎𝑚 + 𝜎𝑎 )2 + 3(𝜏𝑚 + 𝜏𝑎 )2 ]1/2 = [(𝜎𝑎 )2 + 3(𝜏𝑚 )2 ]1/2 (2) Material Yield Strength: (Given 𝑛𝑑 = 3.0) 𝑆𝑦 = 𝜎 ′ 𝑚𝑎𝑥 × 𝑛𝑑 = [(𝐾𝑓 𝜎𝑠 )2 + 3(𝐾𝑓𝑠 𝜏𝑚 )2 ]1/2 × 3.0 RESULTS FOR FILLET RADII TO REDUCE STRESS CONCENTRATIONS AT SHOULDERS: o By choosing AISI 304 Stainless Steel with 𝑆𝑢𝑡 = 73.2 𝑘𝑝𝑠𝑖 and searching for fillet radii yielding exactly 𝑛𝑑 = 3.0: Shoulder 1 Fillet Radius = 0.03 m Shoulder 2 Fillet Radius = 0.05 m 5 D. FEA Visualization of 𝑛𝑑 of Shaft Segments & Stresses After Fillets Added: Figure 10. Snapshots of FEA simulations shown after shoulder 1 fillet of 0.03 m and shoulder 2 fillet of 0.05 m applied to reduce stress concentrations; Top Left shows displacement in mm; Top Right shows strain in mm/mm; Bottom Left shows Von Mises Stresses in MPa; Bottom Right shows checks factor of safety for each region, blue indicating all segments have 𝑛𝑑 ≥ 3.0. General color coding scheme is blue sky blue green yellow red from lowest to highest values for given quantities. - Note that in comparison to the FEA simulations prior to adding shoulder fillets, the von-mises stresses and strains in the shoulder region have dropped significantly, both dropping down from the “green” into the “sky blue” region of the scale and uniform stress and strains in the shaft segment regions have also dropped as well. Also note that the bottom right figure shows that all regions of the graph now have a factor of safety of 3 or above, as the “dark blue” covers the entire shaft. III. Keyway Width & Height Selection: - Using “Table 1: Key Size vs. Shaft Diameter” from Machinery’s Handbook 27th Edition, for a given diameter 𝑑 = 0.2 𝑚 for the center shaft, converting to inches and finding equivalent width and height allowed from the table, converting back to meters for our purposes, the key-way dimensions were determined to be: o Keyway Length = 0.3 (Given) o Keyway Width = 0.07 m 6