Trade Waste Management Plan - large complex activity

advertisement

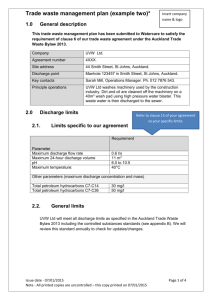

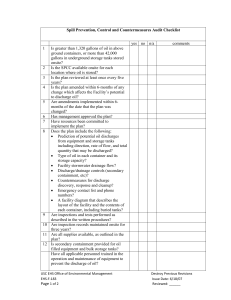

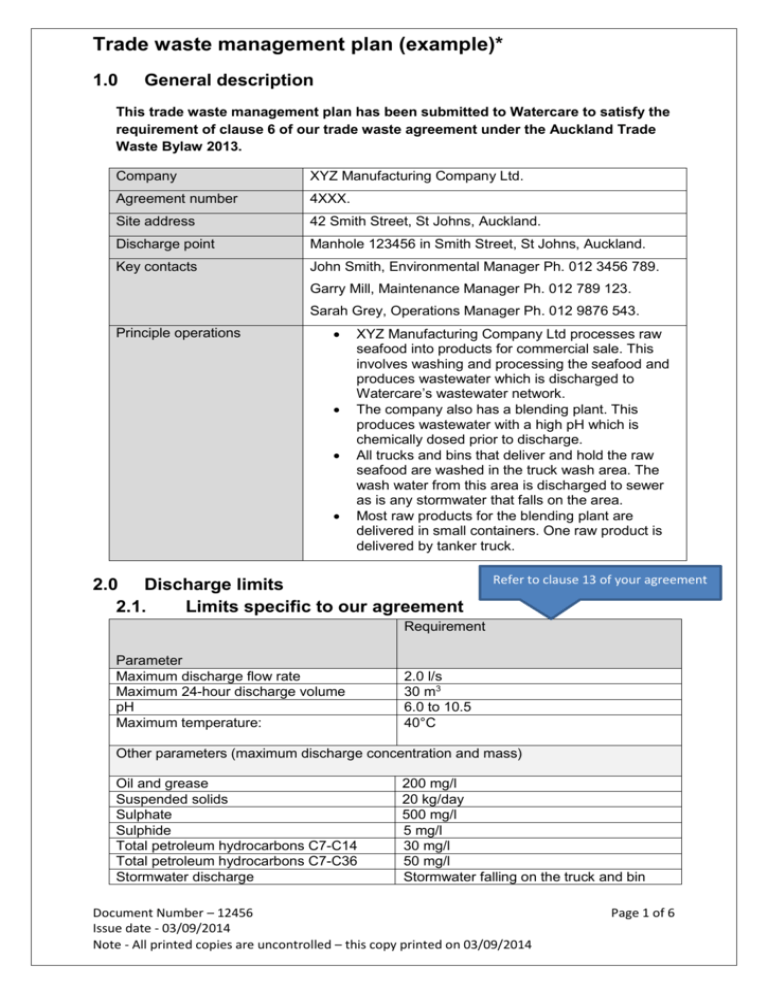

Trade waste management plan (example)* 1.0 General description This trade waste management plan has been submitted to Watercare to satisfy the requirement of clause 6 of our trade waste agreement under the Auckland Trade Waste Bylaw 2013. Company XYZ Manufacturing Company Ltd. Agreement number 4XXX. Site address 42 Smith Street, St Johns, Auckland. Discharge point Manhole 123456 in Smith Street, St Johns, Auckland. Key contacts John Smith, Environmental Manager Ph. 012 3456 789. Garry Mill, Maintenance Manager Ph. 012 789 123. Sarah Grey, Operations Manager Ph. 012 9876 543. Principle operations XYZ Manufacturing Company Ltd processes raw seafood into products for commercial sale. This involves washing and processing the seafood and produces wastewater which is discharged to Watercare’s wastewater network. The company also has a blending plant. This produces wastewater with a high pH which is chemically dosed prior to discharge. All trucks and bins that deliver and hold the raw seafood are washed in the truck wash area. The wash water from this area is discharged to sewer as is any stormwater that falls on the area. Most raw products for the blending plant are delivered in small containers. One raw product is delivered by tanker truck. 2.0 Discharge limits 2.1. Limits specific to our agreement Refer to clause 13 of your agreement Requirement Parameter Maximum discharge flow rate Maximum 24-hour discharge volume pH Maximum temperature: 2.0 l/s 30 m3 6.0 to 10.5 40°C Other parameters (maximum discharge concentration and mass) Oil and grease Suspended solids Sulphate Sulphide Total petroleum hydrocarbons C7-C14 Total petroleum hydrocarbons C7-C36 Stormwater discharge 200 mg/l 20 kg/day 500 mg/l 5 mg/l 30 mg/l 50 mg/l Stormwater falling on the truck and bin Document Number – 12456 Issue date - 03/09/2014 Note - All printed copies are uncontrolled – this copy printed on 03/09/2014 Page 1 of 6 wash area (approximately 50 square metres) can be discharged from the area into our network. See Appendix D for site plan and photos. 2.2. General limits XYZ Manufacturing Company Ltd will meet all discharge limits as specified in the Auckland Trade Waste Bylaw 2013 including the controlled substances standards (see appendix B). We will review this standard annually to check for updates/changes. 3.0 Pre-treatment systems Refer to clause 14.1 of your agreement for your types of pre-treatment and maintenance Control for Solids greater than 30 mm System 6 mm fixed screens on all drains in manufacturing rooms and truck and bin wash area Flow under 2 l/s 1 l/s orifice on outlet from balancing tank in manufacturing room. 1 l/s orifice on outlet from chamber one of TPH/solids sedimentation tank on the truck and bin wash area. Oil and grease under 200 mg/l Three chamber oil and grease (2 m3 each) interceptor connected to drain from manufacturing rooms Suspended solids under 20 kg/day, total petroleum hydrocarbons (C7-C14) under 30 mg/l and total petroleum hydrocarbons (C7C36) under 50 mg/l. Single chamber sedimentation tank and total petroleum hydrocarbons inceptor (5m3) installed on drain from truck and bins wash area. pH between 6.0 to 10.5 pH dosing system which measures pH and doses sulphuric acid to lower the pH. It has one probe which measures the pH in the balance tank and one probe which measures pH on the outlet to the sewer. The balance tank discharges via a 1 l/s orifice to the sewer. Maintenance Daily inspection at end of day. Any material collected on screens is manually removed. Material is disposed to landfill via weekly collection. Recorded on end of day shutdown sheet. Six monthly inspection of orifice. Recorded on six monthly maintenance sheet. Monthly empty and clean by registered waste disposal company. Waste taken off site. Monthly inspection. Recorded on interceptor maintenance sheet. Three monthly empty and clean by registered waste disposal company. Waste taken off site. Monthly inspection. Recorded on TPH/sedimentation tank maintenance sheet. The pH probes are calibrated internally monthly. An annual service and calibration is completed every year by an external contractor. Both are recorded on the pH probe maintenance sheet. A daily inspection is completed on the dosing system and chemicals are replaced as Document Number – 12456 Issue date - 03/09/2014 Note - All printed copies are uncontrolled – this copy printed on 03/09/2014 Page 2 of 6 required. This is recorded on the end of day shutdown sheet. See schematic and photos of each pre-treatment system in Appendix C. See site plan in Appendix D for layout position of pre-treatment systems on site. 4.0 Monitoring and logging systems Include any systems that continuously monitor and/or log your discharge eg. flow, temperature, pH. The pH dosing system includes two pH probes. One is in the balancing tank which provides feedback for the dosing. The second pH probe is in the outlet pipe from the balance tank. It confirms the pH of the discharged water from the production rooms. We will record pH continuously with the outlet probe. This will be reported as a graph to Watercare on a monthly basis. Both pH probes undergo a monthly calibration by internal staff. An annual service and calibration is completed every year by an external contractor. This is recorded on the pH probe maintenance sheet. A daily inspection is completed on the pH probes. This is recorded on the end of day shutdown sheet. 5.0 Risks and controls The table below identifies the on-site risks that could lead to a discharge of non-compliant wastewater to the sewer. The control measures taken to eliminate, isolate or minimise these risks are shown. Risk Flow rate higher than allowed limit Total daily volume discharged higher than allowed limit Non-compliant solids entering trade waste Failure of pre-treatment system Control Orifices on both outlets to control flow to 1 l/s or less. Manual release of wastewater from balancing tank with a sheet to record discharge. Wastewater will be stored overnight if it has reached the total daily allowed volume. Water use at the truck/bin wash is limited by use of high-pressure waterblasting system. 6 mm fixed screens on all trade waste drains which lead to the sewer. Daily cleaning of screens and removal of waste. This waste is disposed offsite. All activities are recorded. Daily and monthly inspections. Repaired and calibrated as required. Systems are routinely maintained. Inspections and maintenance are recorded. Six monthly testing for suspended solids, oil and grease, sulphate, sulphide and TPH and continuous pH monitoring provides feedback on the efficiency of the pre-treatment system. Additional testing will be completed as required to Document Number – 12456 Issue date - 03/09/2014 Note - All printed copies are uncontrolled – this copy printed on 03/09/2014 Page 3 of 6 Risk Control troubleshoot any issues. Spill of stored chemicals Most chemicals are stored in an area which is isolated from the trade waste system. Those chemicals which are in the production areas are bunded. Spill kits are available at each area and all staff are trained in our spill response procedure (see Appendix E). Spill from tanker while unloading raw All unloading occurs in a bunded area which is products isolated from the trade waste system. All staff involved in unloading (including the tanker drivers) are trained in the unloading process and the spill response procedure. Spill kits are available at the tanker unloading area. If there was a major spill it would be disposed of via a registered water disposal company. Fuel or oil spill while tanker unloading See above. All tanker companies are required to provide maintenance logs to ensure tankers are regularly maintained. Power failure In the event of a power failure the water-blasting of trucks and bins will stop as these are mains supply. Other production in the plant will stop due to the requirement for power to run the plant. Wastewater is only discharged manually from the balancing tank when it is within the limits, so a non-compliant discharge will not occur. Once power supply is restored a complete check of the pre-treatment system will be undertaken before production continues. A small backup generator is available on site should it be required to minimise any risk of a non-compliant discharge. Stormwater from other areas entering the The truck and bin wash area is surrounded by a truck and bin wash area small raised hump to prevent stormwater from the surrounding area entering this area (see site plan and photos Appendix D). Spill from or failure of processing All process tanks are located in a bunded area tanks/baths which is isolated from the trade waste system. Rainfall ingress into bins prior to washing Staff are trained to ensure all bin lids are closed at all times. This section should include all risks at your site as well as their controls as per clause 6.1 (c) and (d) of your agreement. It must at least include the risks for flow rate control, failure of a pre-treatment system, spills and power failure. 6.0 Internal notification procedure All staff are trained to notify their superior in the event of an incident. Within 60 minutes of the event the following will occur: The superior will notify the shift supervisor. Depending on the nature of the event it will escalate through the following roles. The most appropriately qualified role will attend to the incident. o Shift Supervisor reports to Operations Manager and Environmental Manager. Document Number – 12456 Issue date - 03/09/2014 Note - All printed copies are uncontrolled – this copy printed on 03/09/2014 Page 4 of 6 o If appropriate the Operations Manager reports it to the Maintenance Manager for any repair requirements. o The Environmental Manager will report the incident to Watercare Services Ltd through the process outlined in the external notification procedure in section 7.0. o The General Manager will be notified of a major incident by the Operations Manager. o This notification procedure is posted on the staff board in the main administration building along with a copy of this plan. Authority will be delegated in the event any role is absent or not available. On-call numbers are identified in the staff board in the main administration building. All incidents will be discussed at our monthly operations meeting. Remedial work will also be monitored and reported at this meeting. Any changes to existing protocols and this plan are reported at this meeting. Include that any incident will be attended to within 60 minutes as per clause 6.1 (e) of your agreement. List any additional methods to avoid, remedy or mitigate the breaches as per clause 6.1 (f). 7.0 External notification procedure In the event of a potential or actual breach of any of the discharge limits of our trade waste agreement, the following will occur: (a) As soon as practicable after becoming aware of the potential or actual breach, we will notify Watercare on (09) 442 2222; (b) Within two working days, we will provide Watercare with written details of the potential or actual breach, and work undertaken to remedy or mitigate any adverse effects to the Watercare network arising from the breach; (c) Within five working days, we will provide Watercare with written details of investigations into the cause of the breach, and implement measures to avoid a similar breach occurring in the future. The plan must include the external notification procedure above as per clause 6.4 of your 8.0 Review of this plan agreement. This plan will be reviewed 12 months after the commencement date and annually thereafter. We will provide Watercare with a copy of the plan if it has changed. If it has not changed we will notify Watercare that it has been reviewed and no amendments have been made. The review of the plan will be discussed on an annual basis at our monthly operations meeting. Document Number – 12456 Issue date - 03/09/2014 Note - All printed copies are uncontrolled – this copy printed on 03/09/2014 Page 5 of 6 9.0 Appendixes Appendix A Trade Waste Agreement 4XXX – Dated 01/09/2014. Appendix B Controlled Substance Standards. Appendix C Schematic and photos of each pre-treatment system. Appendix D Site plan and photos of open areas draining to trade waste drains. Appendix E Emergency spill response procedure. If this procedure forms part of another document, you may simply provide a copy of the relevant section from the other document. *This trade waste management plan is an example only. The plan for your company must reflect your processes and trade discharges at your site. Document Number – 12456 Issue date - 03/09/2014 Note - All printed copies are uncontrolled – this copy printed on 03/09/2014 Page 6 of 6