Conference Session C4

Paper #2241

BULLET PROOF VESTS: THE EVOLUTION OF ARAMID FIBERS

Jann Grovogui (jag168@pitt.edu), Rachel Rohr (rar97@pitt.edu)

Abstract—The most basic form of protection for military

and law enforcement members is the bullet proof vest. This

paper will discuss both the properties of the materials used –

past and present – in bullet proof vests, as well as the

process used to test and develop this form of protection. It

will then go on to analyze the flaws of currently used vests.

Lastly, the ethics surrounding the protection offered to those

who serve will be investigated.

First, the paper will delve into the basic history and

technological advances of body armor from the Greeks who

used steel to 1965 when Kevlar® was first introduced [1].

Next, the National Institute of Justice’s standards at which

manufacturers test bullet proof vests will be established,

emphasizing the requirements of these vests.

An analysis of the materials of which bulletproof vests

are composed will be discussed next. The primary material

being assessed will be Kevlar®; this paper will then

compare the standard vest to Kevlar® treated with colloidal

silica nanocomposites, which has proven more effective.

In conclusion, the topic of ethics will be explored and a

suggestion for the future will be presented. Currently, bullet

proof vests simply protect against gunfire; they do not

address threats from “knives and sharply pointed

instruments, which are different types of threats” [2].

Research should now focus on not simply creating a strong

bullet proof vest, but an all-around protective body armor.

prevented by placing the densest materials available in front

of the body [1].

In 1965, DuPontTM revolutionized the body armor

industry. Protective gear could then be created through the

weaving of high tenacity polymer fibers. These fibers

shifted body armor focus from the macro to the microscopic

scale.

KEVLAR® AS A VIABLE MATERIAL

The historic change from hard body armor – the large

ceramic and metal plates – to soft body armor – the

multilayering of textile material – took place because of that

1965 DuPont™ innovation: Kevlar® [1].

Kevlar® was discovered while scientists were searching

for an improvement from the top man-made fibers at the

time: nylon and polyester. Their current problems consisted

of difficulties creating high tenacity fibers with their

flexible-chain polymers.

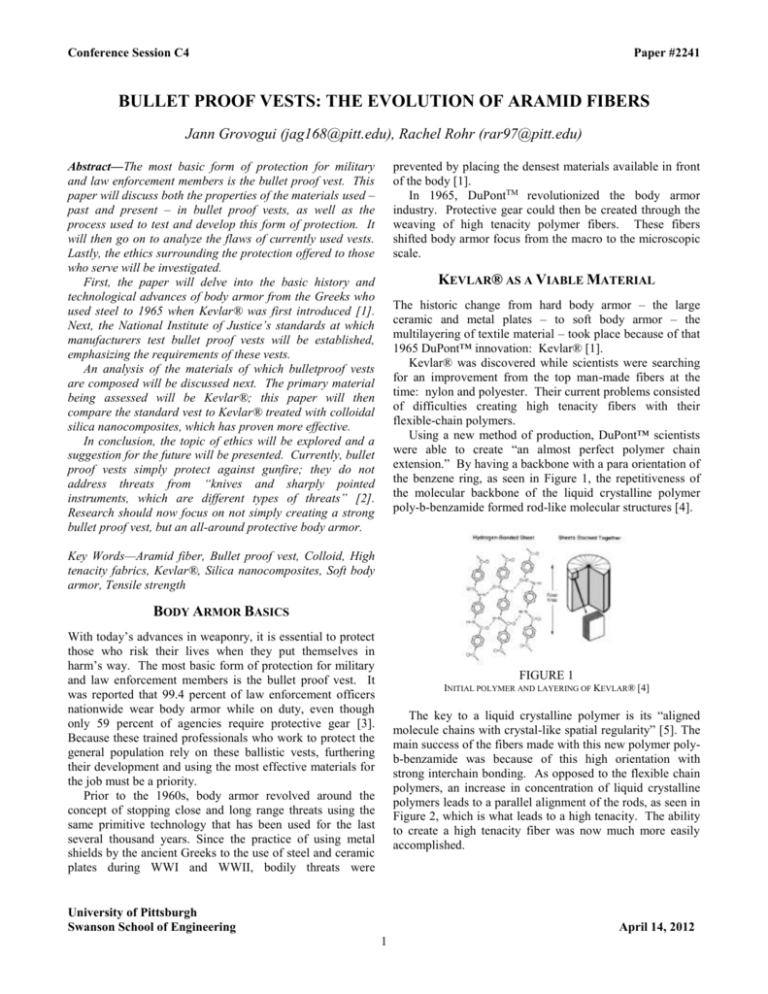

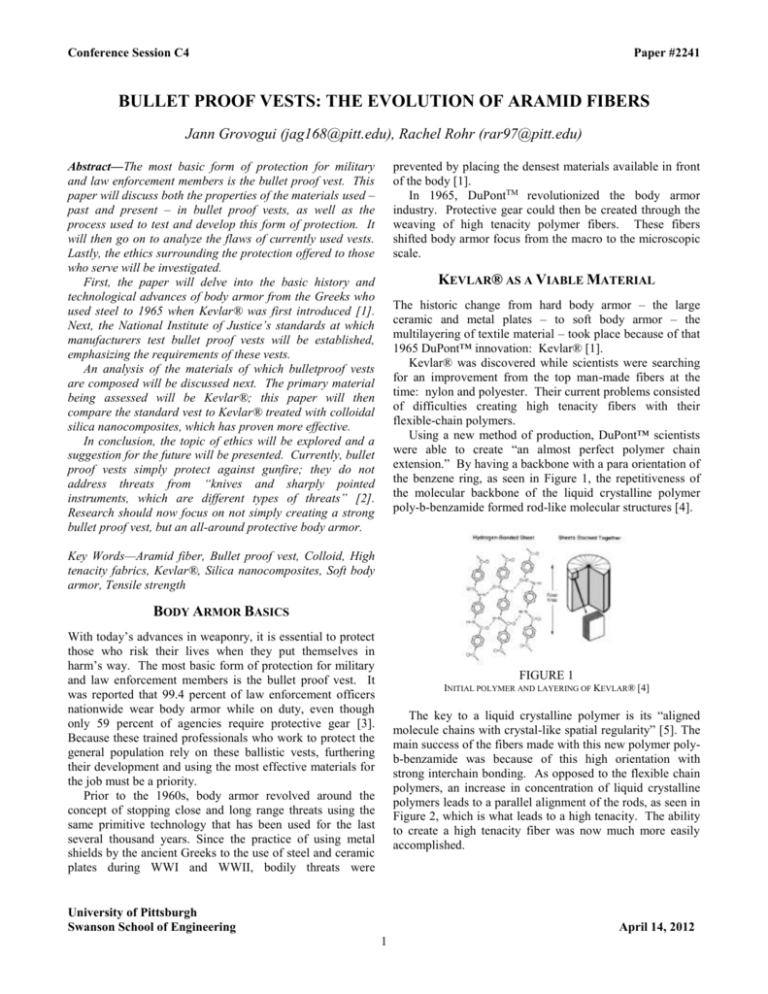

Using a new method of production, DuPont™ scientists

were able to create “an almost perfect polymer chain

extension.” By having a backbone with a para orientation of

the benzene ring, as seen in Figure 1, the repetitiveness of

the molecular backbone of the liquid crystalline polymer

poly-b-benzamide formed rod-like molecular structures [4].

Key Words—Aramid fiber, Bullet proof vest, Colloid, High

tenacity fabrics, Kevlar®, Silica nanocomposites, Soft body

armor, Tensile strength

BODY ARMOR BASICS

With today’s advances in weaponry, it is essential to protect

those who risk their lives when they put themselves in

harm’s way. The most basic form of protection for military

and law enforcement members is the bullet proof vest. It

was reported that 99.4 percent of law enforcement officers

nationwide wear body armor while on duty, even though

only 59 percent of agencies require protective gear [3].

Because these trained professionals who work to protect the

general population rely on these ballistic vests, furthering

their development and using the most effective materials for

the job must be a priority.

Prior to the 1960s, body armor revolved around the

concept of stopping close and long range threats using the

same primitive technology that has been used for the last

several thousand years. Since the practice of using metal

shields by the ancient Greeks to the use of steel and ceramic

plates during WWI and WWII, bodily threats were

FIGURE 1

INITIAL POLYMER AND LAYERING OF KEVLAR® [4]

The key to a liquid crystalline polymer is its “aligned

molecule chains with crystal-like spatial regularity” [5]. The

main success of the fibers made with this new polymer polyb-benzamide was because of this high orientation with

strong interchain bonding. As opposed to the flexible chain

polymers, an increase in concentration of liquid crystalline

polymers leads to a parallel alignment of the rods, as seen in

Figure 2, which is what leads to a high tenacity. The ability

to create a high tenacity fiber was now much more easily

accomplished.

University of Pittsburgh

Swanson School of Engineering

April 14, 2012

1

Jann Grovogui

Rachel Rohr

protective that hard body armor. In fact, “Kevlar® fiber is

five times stronger than steel on an equal weight basis,

offering superior protection against fragmentation and

ballistic threats” [8].

DuPont™ currently stresses the fact that “there is no such

thing as completely ‘bullet proof’ armor,” and should instead

be more accurately described as “bullet-resistant” [9]. These

levels of resistance vary, and therefore not all vests can

provide the same protection. Through careful studies in

their Ballistic Labs in Virginia and Switzerland and as

established by the standards from the National Institute of

Justice, DuPont™ has discovered the various levels of their

materials which can best protect against specific bullet types.

Based on these varying levels of ballistic performance, the

National Institute of Justice has classified body armor into

five different types:

FIGURE 2

DIFFERENCE IN RIGIDITY BETWEEN PREVIOUSLY-USED

MAN-MADE FIBERS AND KEVLAR® [4]

Using the same technology which created their first high

tenacity polymer over the next few years, DuPont™ was

then able to develop a fiber of poly-paraphenylene

terephthalamide, as seen in Figure 3, which became their

high-strength aramid fiber seen today.

Type II-A protects against 9mm and .40 S&W caliber

bullets

Type II protects against 9 mm and .357 Magnum bullets

Type III-A protects against higher velocity 9 mm and

.44 Magnum bullets

Type III protects against rifles

Type IV protects against .30 caliber armor piercing

bullets [10]

By adjusting the layers of Kevlar in body armor as well

as the density, these different types can be created. This

variety is what allows men and women of different

professions to all use Kevlar® bullet proof vests. As they

enter different dangerous situations, they need the best

protection for what harm they will most likely face. Type IIA body armor is often used by police officers while Type III

is often used by military in tactical situations.

In addition, Kevlar® is so popular because of its light

weight and comfort. Law enforcement officers have relied

on Kevlar® for more than 30 years. For the same time,

every branch of the Armed forces has used Kevlar® vests.

FIGURE 3

POLY-PARAPHENYLENE TEREPHTHALAMIDE POLYMER [6]

Kevlar® and its aramid fibers, which can be seen in a

variety of places including the military, automobiles, and

fiber optics, is characterized by its unique properties which

include: high tensile strength at low weight, low electrical

conductivity, and flame resistance [4].

ADVANCING KEVLAR TECHNOLOGY

Since its development in the 1960’s there have been

numerous advancements made to improve the abilities of

Kevlar. Many more types of high tenacity fibers have been

developed such as Dyneema®,Twaron®, and several others

[11]. These new advancements have either enhanced the

strength to weight ratio of these individual fibers or

improved other qualities such as resistance to heat [12].

However, one of the most impressive advancements has not

been the development of a new fiber, but rather a way to

improve the properties of all high tenacity fibers. This new

technology involves the impregnation of colloidal silica into

the fibers of vests, also referred to as shear thickening liquid

[13].

A colloid is a “mixture in which a dispersed substance

(which is solute-like) is finely divided in a dispersing

Effectiveness in Bullet Proof Vests

By 1973, Kevlar® could be seen in bullet proof vest designs

for use in field trials. In 1976, a report was released which

concluded that this new soft body armor was effective and

ready for use [7].

Kevlar® so effectively “catches” a bullet because of its

woven multilayer fabric. Each layer works together to

engage a high-velocity projectile and attempt to stop it as

quickly as possible [4].

“The engaged fibers absorb and disperse the energy of

the impact, transferring it to other fibers at crossover points

in the weave of the body armor” [8]. The subsequent layers

absorb energy and reduce the force felt by the wearer.

Though labeled soft body armor, it by no means is less

2

Jann Grovogui

Rachel Rohr

medium (which is solvent-like)” [14]. A colloidal mixture is

any liquid that has with in it small spherical particles of radii

between 1nm and 1000nm [14]. Colloids are incorporated

into high tenacity fibers through a relatively short process,

which involved first the soaking of fabrics in a basin filled

with colloidal silica suspension. The material soaks for an

hour before then being removed from the colloid. Excess

liquid is then driven out of the fabric through a pressing

process and then finally the fabric is baked at 80°C for an

additional hour [11].

After this short process, the

transformation is complete and the strength of the fibers are

significantly improved.

the inter-fiber friction, causing there to be more dispersion

of forces.

In order to test this, of course, experiments had to be

performed. One such test was devised in order to test “neat”

fibers–fibers that were not impregnated with the colloid–

versus fibers treated with three different sized colloids (110

nm, 380nm, and 540nm) [11]. The tests that were performed

included but were not limited to; ballistic tests and string

pull tests.

Ballistic tests are the most obvious test that would occur

during testing of bullet proof vests. This involves the

launching of a projectile into woven fibers and examining

the impact the projectile has on them. In this experiment,

clay was also placed behind the woven fibers so that the

impact behind the cloth could be observed afterwards.

In addition to the ballistic test, a string pullout test was

performed. In an experiment like this, a machine is built to

pull out the string on the frayed edges of woven fibers. This

will test the inter-fiber friction which is usually a good

determinant of how well a certain woven fabric will disperse

a force put upon it. For a single string pull-out experiment

there are usually six factors that affect the result of the test.

These factors include: “…fabric style, material properties

such as elastic modulus and strength of the yarn, fabric

length, transverse load, surface treatment, and pull-out

loading rate” [16]. In the case of vests impregnated with

silica colloid, the colloid is the only difference between the

neat and treated vests is the surface treatment. Therefore any

difference in results will be due to the colloid because it is a

surface treatment of the vest.

FIGURE 4

Test Results

(ABOVE) UNTREATED KEVLAR® MICROSCOPY IMAGE

(BELOW) KEVLAR® TREATED WITH COLLOIDAL SILICA NANOCOMPOSITE

[15]

Due to the relatively new nature of shear thickening

technology, there are very few experiments that have been

performed. However, because of the potential of colloid

impregnated ballistic fibers, it is important for scientists to

continue their studies on this new technique in order to fully

test the qualities that this material possesses. Without such

research, it would be unethical to produce and use this

fantastic material in bullet proof vests without knowing if it

has certain flaws.

Bok-Won Lee, Il-Jin Kim, and Chun-Gon Kim performed

one experiment on the properties of silica colloid

impregnated fibers. In this experiment, two tests that were

performed were the string pullout and projectile tests.

In the projectile test, an interesting result was found.

Woven cloth treated with three colloid particle sizes were

tested (approximately 100nm, 300nm, and 500nm) along

with an untreated sample. These four fabric samples were

clamped by the team on each edge to a frame and clay was

used to back the samples in order to measure the back face

deformation of the fabric. When a 5.52-gram projectile was

launched at approximately 224 m/s at the fabrics, all the

fabrics except for the cloth impregnated with the 100 nm

colloid successfully arrested the projectile [11].

Despite the small size of the particles and the fact that

they are immersed in a liquid, this technology is surprisingly

effective and has incredible results. The first reason that this

technology is effective is that the addition of a liquid into the

fiber adds almost no weight or stiffness to the fabric [11]. In

addition, the stopping power is greatly improved. For

example, four layers of Kevlar® treated with 8 mL of

colloidal silica have the same strength properties as 14 layers

of dry Kevlar [15].

Shear Thickening Liquid Treatment

The basic reason that the fibers are significantly enhanced

when impregnated with silica is in part due to the mechanics

behind how bulletproof vests operate. The way that these

vests work is that when impacted by a bullet or other

projectile, the fibers within them interact with each other and

quickly disperse the concentrated force over a larger area of

the vest [16]. The theory behind why silica colloids improve

the stopping power of vests is that the colloid may improve

3

Jann Grovogui

Rachel Rohr

Another interesting finding from the results of this test

showed that in general, as particle size decreased, energy

dissipation increased; however, untreated cloth consistently

dissipated the least energy. The general reason that smaller

particles dissipate more energy is because there are more

particles with more surface area to interact, which in turn

causes more inter-fiber frictional force. Considering this

concept, it is bizarre that not only would the 100 nm

particles dissipate less energy than the 300nm and 500nm

particles, but it actually weakened the fibers because the

cloth was actually penetrated when impregnated by 100nm

particles but dissipated over 90% of the projectiles energy

when it was untreated [11].

This abnormality in this particular data proves that this

technology needs to be further researched. Because so few

studies have been done, it is unclear whether 100 nm

particles are too small to have any positive affect on aramid

fibers or if this data occurred because of an experimental

flaw. Perhaps there are more weaknesses of shear thickening

fluid that scientists are unaware of, and again this is why

aramid fiber technology needs to be researched in order for

us to be able to utilize this technology affectively.

Another interesting result occurred in the string pullout

test. As the strings were being pulled from the fabric, it was

found that at low speeds, all four fabrics that were tested

required nearly the same force to pull out the fibers.

However, as the speed of pullout increased, the colloids

begin to react to the speed. The special quality that shearthickening fluids such as this colloid have is that “during

normal use, they flow as easily as conventional liquids,” but

“when subjected to sudden stresses that make them flow at

higher shear rates, they instantly turn rigid and act like a

solid material” [13]. Because of this quality, there were

certain speeds of pullout that were revealed in which the

colloid switched from acting like a liquid to acting more

rigid and solid-like. In addition, the different sized colloids

reacted in this way at different speeds. For example,

between 400 and 500 mm/min the 300nm colloid reached its

shear thickening point and the resistance of the fiber it was

reinforcing greatly increased making it the toughest fibercolloid combination. However, at about 1356 mm/min the

100 nm colloid reached it shear thickening point and the

pullout force needed to pull the string increased by 89.2%

making it the toughest fiber-colloid combination at this point

[11]. This shows that different sized colloids may be more

effective for stopping projectiles at different speeds.

This knowledge is very important to ensure the safety of

those wearing vests. This is because that could mean that a

soldier protected by high velocity projectiles could be

injured by something more slow moving such as an arrow.

Because of intricacies such as this, more engineers need to

perform follow up experiments in order that shearthickening technology can be fully understood and utilized

in body armor. However, new aramid fiber technology is

not the only aspect of body armor that needs to be improved.

There are many factors that affect the durability and strength

of body armor and can cause significant degradation. These

factors cannot be controlled, but the need to create aramid

fibers that are more resistant to these outside factors is vital

for the full protection of those who use ballistic vests.

DOWNFALLS OF CURRENT BALLISTIC VESTS

Though ballistic vests have certainly achieved great

advancements since steel and ceramic plates during the two

World Wars, there are still many developments that need to

be made.

Ethically, these are issues that need to be focused upon

immediately. Men and women rely on these vests daily to

save their lives; research should therefore be done to make

them as effective as possible. A number of problems can be

addressed.

Environmental Effects on Vest Quality

Since wearers of bullet proof operate in all types of

environments, vests need to be able to withstand the variety

of elements these wearers face. Currently, Kevlar®, like all

materials, has points where it can no longer be as effective.

Providing the most protection at a neutral pH, Kevlar®

significantly reduces in strength when exposed to strong

acids and bases, as seen in Figure 5. It shows the break

strength–which prevents a sample from failing when

enduring loads–of Kevlar® remaining at different pHs [17].

FIGURE 5

EFFECT OF VARYING PHS ON KEVLAR® [4]

The U.S. Department of Justice and National Institute of

Justice report that temperature is also a worry with bullet

proof vests. Although Kevlar® degradation is mostly a

problem at extreme temperatures not faced on a daily basis,

the extended period of time which ballistic vests are worn

allows lower temperatures to be a problem as well. This is

mainly due to the fact that vests have such a long time to

endure such degradation; the typical life of a bullet proof

vest is three to five years [7]. As exposure to high

temperature continues, the tensile strength of a material,

which is “the maximum stress that a material can withstand

while being stretched or pulled before necking, which is

when the specimen's cross-section starts to significantly

contract,” is reduced [18].

4

Jann Grovogui

Rachel Rohr

Prolonged exposure to UV and visible light additionally

harms bullet proof vests; it can cause “loss of mechanical

properties, depending on wavelength, exposure time,

radiation intensity and product geometry” [4]. When the

absorption spectrum of Kevlar® is overlapped with the

sunlight spectrum, as shown in Figure 6, there is sufficient

energy to break the chemical bonds of the fiber and therefore

maximum degradation. For this reason, body armor should

never be dried outdoors, yet this cannot always be avoided.

The preliminary experiment described above lead to

further experiments and to another performed by the

National Institute of Standards and Technology. In this

follow up experiment, the aim was to discover if there would

be a dramatic degradation in aramid fiber strength when the

fibers were woven as is found in bullet proof vests. Another

aim was to discover why this effect was occurring, in order

to find a way to prevent this reduction in strength.

A machine was constructed that would apply a force

consistently that would replicate a folding in woven aramid

fibers. The machine ran fibers through either 5,500 cycles

or 80,000 cycles of folding, which is an amount not too

inconsistent with the estimate of folds stated earlier [20].

The results of this experiment showed that woven fibers

folded 5,500 times showed a strength reduction of 14% and

that those folded 80,000 times showed a strength reduction

of 41%. In addition, when externally examined through a

scanning electron microscope, no external damage was

observed. This leads to the conclusion that folding causes

internal damage of the fibers [20]. The internal damage that

was caused was predicted to be an increase in the internal

flaw density that all aramid fibers contain. These defects are

due to tiny “needle like internal voids having approximately

2.4 nm diameters and length of 30 nm which are connected

to each other through cracks or openings between micro

fibrils” [21]. Folding creates an increase in the flaw density,

which in turn causes a “higher probability of the fiber to

form a critical flaw big enough to fracture the fiber as the

tensile stress increases” [20].

FIGURE 6

UV AND VISIBLE LIGHT EFFECT ON KEVLAR® [4]

Day-to-Day Degradation

There are many factors, most of them being environmental,

that affect the strength of bullet proof vests. One factor that

is not environmental is the effect of folding on aramid fibers.

The specific type of folding in body armor that can cause its

degradation is the bending of the armor around joint areas

that occur due everyday movement. In fact, a simple

estimation is that “a body armor user might bend at the wait

(e.g., when entering or exiting a vehicle) 4 times per hour,

40 hours per week, 50 weeks per year, which would result in

8,000 folding cycles per year, or 40,000 folding cycles over

5 years” [19]. This estimate is consistent with the daily

activity that may be seen by a police officer; however this

may not be consistent with the amount of activity that an

active duty soldier would perform. In this case, a much

higher activity level would be observed, leading to more

movement and more eventual folding of body armor.

Because the movement cannot be measured accurately based

on a simple statistical analysis, the activity level of police

officers will be considered. Now that it is seen how many

times a piece of armor may be folded, it is safe to assume

that this factor cannot be ignored and that a way to

determine how much effect folding has on body armor but

be found.

One study was carried out by J.H. Kim, N.

Brandenburgh, W. McDonough, W. Blair, and G.A. Holmes,

in which 50 fibers of polybenzoxazole (PBO), a common

aramid fiber, were folded once each. Before and after each

fold, the single fibers were tested to find their strain-tofailure ratio. It was found that after just a single fold, there

was a reduction in the strain-to-failure ratio by 10% [20].

FIGURE 7

EVIDENCE FOR THE DECREASE OF TENSILE STRENGTH

AS CYCLES OF FOLDING INCREASE [15]

As a result, it can be seen that the folding of aramid fibers

through everyday use can cause a massive decrease in the

strength of ballistic vests. This is a flaw that has not been

overcome and is definitely one that should be looked into

further. According to the calculations made, it could be

possible for a vest to decrease in strength over the course of

10 years up to 41% and in the course of one year over 14%

simply to the everyday movement [20]. Of course, these

time estimates are based on the activity level of a police

officer. As stated earlier, in the case of an active duty

soldier, the level of activity would be much higher and thus

5

Jann Grovogui

Rachel Rohr

lead to a faster rate of body armor degradation, possibly

within the time of a single tour of duty, leading to much less

protection for those serving on the front lines. Because of

this great weakness in the properties of aramid fibers, it is

important for engineers to continue research and

development in order to not let body armor wearers enter

dangerous situations with the false assumptions that they are

protected.

In addition to problems with the material itself, a vital aspect

of body armor that needs to be reevaluated is a relatively

simple one: covering the body. Due to the need for

movement, ballistic vests cannot provide complete

protection. “In firearms assaults on officers, bullets may

strike in vital regions not protected by body armor, notably

the shoulder, underarm, and the gap between the front and

back armor panels. If a bullet strikes close to the edge of the

body armor panel, it can slide off the armor panel or backing

and penetrate the torso” [2]. Because parts of the body are

left exposed, multiple deaths occur each year even when

body armor is worn, most of which include gunshots to the

head or upper torso [7].

This separation forces wearers to choose one type of

protection over the other. Bullet proof vests, which are

characterized by superb protective abilities from gunfire,

“may not be completely effective against attack by a knife or

other sharp instrument, such as an ice pick” [7].

Unfortunately, bullet proof vests do not even protect against

all bullets, let alone these other dangers. Five types of bullet

proof vests exist because not one of these can protect against

all potential projectiles. Though police typically face lower

velocity 9mm bullets in their line of work (for which type IIA body armor is adequate), should a high-tense barricade

confrontation arise, their daily bulletproof vests will not be

suitable for the job. In these situations, “officers have died

from wounds received from weapons or ammunition

exceeding the rated protection of the armor” [10].

Leaving officers and other military personnel more

susceptible to blunt force trauma, stabbings, and other

projectiles for which their vests are not designed is therefore

a huge ethical issue. Every day, Chief of Police and

Commanding Officers send their men and women into

harm’s way partly unprotected. Not only should these men

and women understand that, but also developments should

be made in body armor to allow them as much protection as

possible.

Lack of Education

CONTINUING DEVELOPMENT

Since so many actions and environments could deteriorate

bullet proof vests, there is a strong need for users to be

educated about proper use. Though all vest companies

provide information about how to best maintain the quality

of their products, those using them often do not take careful

note [7].

For example, each model of armor has clear instruction

about how to clean the components. Inserts of body armor

should typically be cleaned with cold water and a sponge. If

soap is used, it must be removed completely, as it “prohibits

the accumulation of residual soap film, which can absorb

water and reduce the protective properties” [7].

Directions are also clear to say that body armor should be

regularly checked for signs wear; should the user choose to

ignore this step, they may be entering harmful situations

with potentially faulty defense.

As of January 2012, soft body armor has saved the lives of

more than 3,000 members of law enforcement alone since

the 1970’s, let alone the military personnel who use the same

body armor on a daily basis [22]. Soft body armor, which

was developed through the use of Kevlar®, is used by these

two groups because of its strength and comfort compared to

alternative body armor materials, especially much heavier,

less flexible hard body armor.

Since the development of the first aramid fiber in 1965,

numerous stronger fibers have been created such as

Dyneema® and Twaron® which have led to body armor

improvements [11]. However, developments cannot stop

there. More research into possible fiber enhancements needs

to be explored, such as the inclusion of sheer thickening

fluid into the woven fabrics.

Further, new research into maintaining the strength of

fibers in all environments should be completed, allowing for

maximum protection throughout a longer period of time.

Temperature resistance, ability to withstand all acidities,

endurance through exposure to UV and visible light, and

flexibility while maintaining strength are all areas which

need improvements.

Ultimately, body armor comes down to saving lives. “Of

the approximately 1,200 officers killed in the line of duty

since 1980, more than 30% could have been saved by body

armor” [4]. With continued developments, body armor can

save an even great number of people who risk their lives to

protect others.

Lack of Coverage

Protection Against Alternative Attacks

Possibly the most significant topic of education is

guaranteeing that ballistic vest users understand what exactly

their vests protect against.

Today, law enforcement and military troops face various

types of threats. Companies have created protective vests

for many of these; in addition to bullet proof vests, stab, bite,

and blunt force trauma vests all exist. The unfortunate

reality is that these all exist because no one vest can protect

against each of these threats.

6

Jann Grovogui

Rachel Rohr

id=66645616&titleid=3825&accname=University+of+Pittsburgh&checksu

m=541EBAA D94CCC9A1876600912982D6B9

[16] Hong, Ji Hye (July 22, 2011) “Yarn Pull-Out Behavior Under Dynamic

Loading”

UMI

Dissertaion

Publishing.

[Online].

Available:

http://proquest.umi.com/pqdlink?vinst=PROD&fmt=6&startpage=1&vnam

e=PQD&RQT=309&did=2517311471&scaling=FULL&vtype=PQD&rqt=

309&cfc=1&TS=1330270023&clientId=17454

[17] (2011). “Break Strength Testing.” AMETEK, Inc. [Online].

Available:

http://www.chatillon.com/test-solutions/test-types/breakstrength-testing.aspx

[18] (2010). “Capabilities.” S&P Heat Treating. [Online]. Available:

http://www.spheattreating.com/index-1.html

[19] Forster, Amanda L., Pierre Pintus, Guillaume H.R. Messin, Pintus,

Guillaume H.R. Messin, Michael A. Reilly, Sylvain Petit, Walter Rossiter,

Joannie Chin, Kirk D. Rice. (May 7, 2010) “Hydrolitic Stability of

Polybenzobisoxazole and Polyterephthalamide Body Armor” [Online].

Available: http://www.sciencedirect.com/science?_ob=MiamiImageURL&_

cid=271544&_user=10183724&_pii=S0141391010003952&_check=y&_or

igin=article&_zone=toolbar&_coverDate=28-Feb-2011&view=c&originCo

ntentFamily=serial&wchp=dGLbVlkzSkzk&md5=51edecc95d37c3671d78

3a46d 4c954f7/1-s2.0-S0141391010003952-main.pdf

[20] Holmes, Gale A., Jae-Hyun Kim, Derek L. Ho, Walter G. McDonough

(2010) “The Role of Folding in the Degradation of Ballistic Fibers”

Polymers Division, National Institute of Standards and Technology

[Online]. Available: http://onlinelibrary.wiley.com/doi/10.1002/pc.20870/

pdf

[21] T. Kitigawa, H. Murase, and K. Yabuki, J.Polym. (1998). Sci. Part B:

Polym. Phys., 36, 39.

[22] (2012). “Voluntary Ballistic-Resistant Armor Compliance Testing

Program.” Justice Technology Information Network. [Online]. Available:

http://www.justnet.org/Pages/bodyarmor.aspx

REFERENCES

[1] Kamenidis, Panagiotis. (May 2009). “Effect of Trapped Air on Heat

and Moisture Resistance of Multi-Layered Soft Body Armors.” Oklahoma

State University [Online]. Available: http://proquest.umi.com/pqdlink?

vinst=PROD&fmt=6&startpage=1&vname=PQD&RQT=309&did=178981

2731&scaling=FULL&vtype=PQD&rqt=309&cfc=1&TS=1326053089&cli

entId=17454

[2] (July 2008). “Ballistic Resistance of Body Armor.” National Institute

of Justice. [Online]. Available: https://www.ncjrs.gov/pdffiles1/nij/

223054.pdf

[3] (May 2010). “Body Armor.” The FBI Law Enforcement Bulletin.

[Online]. Available: http://go.galegroup.com/ps/i.do?id=GALE%7CA22

7073995&v=2.1&u=upitt_main&it=r&p=AONE&sw=w

[4] (2011). “Kevlar® Technical Guide.” DuPont. [Online]. Available:

http://www2.dupont.com/Kevlar/en_US/assets/downloads/Technical%20Gu

ide%20for%20KEVLAR_2011.pdf

[5] Wang, Xuefeng, Jonathan Engel, and Chang Liu. (2003). “Liquid

crystal polymer (LCP) for MEMS: processes and applications.” University

of Illinois. [Online]. Available:

http://www.mech.northwestern.edu/

medx/web/publications/papers/102.pdf

[6] (2006). “Kevlar®.” Engineering Library. [Online]. Available:

http://www.engineering.com/Library/ArticlesPage/tabid/85/articleType/Arti

cleView/articleId/91/KEVLAR.aspx

[7] (2001). “Selection and Application Guide to Personal Body Armor.”

National Institute of Justice. [Online]. Available: https://www.ncjrs.gov/

pdffiles1/nij/189633.pdf

[8] (2011). “Body Armor Facts.” DuPont. [Online]. Available:

http://www2.dupont.com/Kevlar/en_US/uses_apps/body_armor/about_body

_armor.html

[9] (2011). “Bulletproof Law Enforcement Body Armor.” DuPont.

[Online]. Available: http://www2.dupont.com/Kevlar/en_US/uses_apps/

body_armor/law_enforcement_body_armor.html

[10] “Body Armor Classifications.”

Global Security.

[Online].

http://www.globalsecurity.org/military/systems/ground/bodyarmor1.htm

[11] Lee, Bok-Won, Il-Jin Kim, and Chun-Gon Kim. (October 2009). “The

Influence of Particle Size of Silica on the Ballistic Performance of Fabrics

Impregnated with Silica Colloidal Suspension.” Journal of Composite

Materials. [Online]. Available: http://jcm.sagepub.com/content/43/2

3/2679.full.pdf+html

[12] Bourbigot, Serge, Xavier Flambard, Franck Poutch (February 2001)

“Study of the Thermal Degradation of High Performance Fibers—

Application to polybenzazole and P-Aramid Fibres” Elsevier: Polymer

Degredation

and

Stbility.

[Online].

Available:

http://www.sciencedirect.com/science?_ob=MiamiImageURL&_cid=27154

4&_user=10183724&_pii=S0141391001001598&_check=y&_origin=articl

e&_zone=toolbar&_coverDate=31-Dec2001&view=c&originContentFam

ily=serial&wchp=dGLzVlSzSkzS&md5=2c36e615df1277f7667685a17c83

5b93/1-s2.0-S0141391001001598-main.pdf

[13] Brown, Alan S. "Liquid armor stiffens when threatened." Mechanical

Engineering-CIME May 2006: 25. Academic OneFile. Web. 26 Feb. 2012.

[Online]. Available: http://go.galegroup.com/ps/i.do?id=GALE%7CA159

697092&v=2.1&u=upitt_main&it=r&p=AONE&sw=wupitt_main&it=r&p

=AONE&sw=w

[14] Tro, Nivaldo. (2011). Chemistry: A Molecular Approach. Upper

Saddle River, New Jersey: Pearson Prentice Hall. pp. 550 – 552.

[15] Li, X, H.L Cao, S. Gao, F.Y. Pan, L.Q. Weng, S. H. Song, and Y. D.

Huang. (April 2008). “Preparation of Body Armour Material of Kevlar

Fabric Treated with Colloidal Silica Nanocomposite.” Institute of Materials,

Minerals, and Mining. [Online] Available: http://docserver.ingentaconnect.

com/deliver/connect/maney/14658011/v37n5/s8.pdf?expires=1326338891&

ADDITIONAL SOURCES

Bacchus, Joe. (2006) “U.S. Army Research Laboratory in Aberdeen using

particles to stop bullets.” Dolan Media Newswires. [Online]. Available:

http://galenet.galegroup.com/servlet/BCRC?srchtp=adv&c=1&ste=31&tbst

=tsVS&tab=2&aca=nwmg&bConts=2&RNN=A148197353&docNum=A1

48197353&locID=upitt_main

(2012). “Aromatic Substitution Reactions.” Michigan State University.

[Online].

Available:

http://www2.chemistry.msu.edu/faculty/reusch

/virttxtjml/benzrx1.htm

(2011). “Kevlar® Reference Designs for Vests made with DuPont™

Kevlar®/Kevlar® XP™.”

DuPont.

[Online].

Available:

http://www2.dupont.com/Kevlar/en_US/assets/downloads/DSP_

KevlarXP_ReferenceDesigns_K23338.pdf

ACKNOWLEDGMENTS

We would like to thank Nick Andes for helping us to

develop our conference paper, as well as our Co-Chair

Caroline Repola. Also, thank you to Hans Mattingly for his

feedback throughout this process.

7