Introduction of Aqueous Cleaning into High Reliability

advertisement

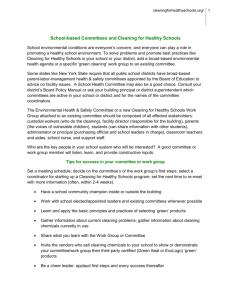

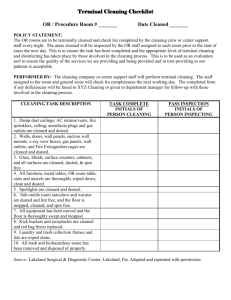

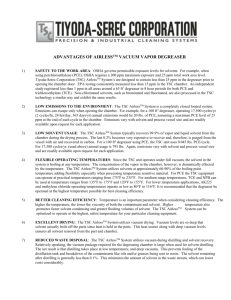

Introduction of Aqueous Cleaning into High Reliability Electronic Assemblies Casker, Wendy J. 5/1/2014 Abstract Currently, vapor degreasing is the sole method for batch cleaning of printed circuit board assemblies (PCBA’s) in the Advanced Electrical Assembly area of Johns Hopkins University Applied Physics Laboratory (APL). Vapor degreasing requires the use of a qualified degreasing fluid. The fluid cleans very effectively, however it does attack plastics, Ultem, and several polymerics materials used in the assembly process. Once those materials are introduced on an assembly, it cannot be cleaned in the degreaser, and instead, must be soaked in isopropyl alcohol (IPA). The vapor degreasing fluid is also very costly. Vapor degreasing also requires the use of solder paste and flux which can be cleaned in the solvent, thus limiting the selection of pastes available to build high reliability hardware. As a result of the expense and limitations of the degreasing solvent, APL elected to explore a pathway to introduce aqueous cleaning into the assembly process. The process consisted of assembling ten (10) IPC-B-52 test vehicles, cleaning a subset in the current degreasing system, and the remainders were cleaned in a saponified aqueous batch cleaning system. All of the units were the subjected to IPC-9202 standard SIR testing and Ion Chromatography performed by an independent laboratory. As an added benefit, the introduction aqueous cleaning process will the use of costly degreasing solvent and elimination of costly disposal of the solvent. With the use of a closed loop system, there is no discharge of any water or cleaning agents into a drain furthering the environmental benefit. The cleaning agents are much less expensive than the degreasing fluid, and are not prone to evaporation due to the closed loop nature of the processing equipment. Aqueous solutions are also compatible with many plastic components and polymerics materials, thus allowing improved cleaning later in the assembly process.