Standard Operating Procedure for Liquid Nitrogen

advertisement

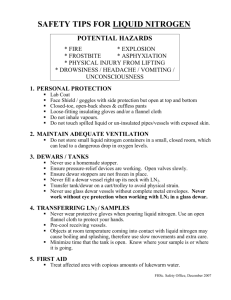

ENVIRONMENTAL HEALTH AND RADIATION SAFETY UNIVERSITY OF THE SCIENCES Liquid Nitrogen: Ordering, Handling and Transportation. Ordering: Liquid nitrogen should be ordered through the University’s stockroom central purchasing system utilizing our trusted and approved vendors assuring proper delivery, quality, security and account management. Handling: Liquid nitrogen tanks, often referred to as cryogenic storage tanks, are cylindrical in shape. They are designed to ASME specifications for the pressures and temperatures involved. On campus we have direct delivery to the laboratories of all liquid nitrogen tanks. Only larger liquid nitrogen storage tanks are mounted with wheels and can be moved when emptied by the end user. Intermediate sized liquid nitrogen storage tanks require special carts and training that are not currently available on campus and require vendor assistance. Liquid nitrogen storage containers and cryogenic storage tanks must always be stored and transported in the upright position. PPE: When handling liquid nitrogen, unvented or indirect venting chemical splash safety googles are required. If pouring or filling a secondary container from a larger cryogenic storage tank or Dewar a face-shield is required. Waterproof insulated gloves are required for use and for transport. Long pants, closed shoes and a lab coat are the only acceptable attire for dispensing, using and transporting liquid nitrogen. When using larger amounts of liquid nitrogen (>25 L) an apron should also be worn. Storage: Liquid nitrogen has a large expansion ratio of liquid to gas (1:696) and requires a minimum of six air exchanges per hour for adequate ventilation. OSHA has established a 19.5% oxygen concentration as the minimum for working without supplied air. Typical laboratories around campus accommodate this minimum requirement with regards to the use and storage or liquid nitrogen. If there is an area that you are not certain will accommodate the minimum requirements, contact Facilities Services for a proper analysis of the ventilation system in that area. Some areas that do not accommodate proper ventilation and are at risk for oxygen displacement are elevators, some storage closets/areas, and cold rooms. Liquid nitrogen tanks should also be stored and used in secure locations away from weather and temperature extremes. ENVIRONMENTAL HEALTH AND RADIATION SAFETY UNIVERSITY OF THE SCIENCES Venting: All liquid nitrogen cryogenic storage tanks are equipped with pressure relief devices that regulate the internal pressure. Normally venting will occur while in storage. The manufacturer should be called if excessive continuous venting occurs (as well as the area evacuated). However, typical release is normal and can be managed in a properly ventilated area. Slight frost can also naturally occur at the top of a liquid nitrogen storage tank. Contact the manufacturer if excessive ice build-up occurs at the head of the tank as this can result in a clogged release valve contributing to dangerous mounting pressure making dispensing unsafe and often impossible. All containers used for the storage and dispensing of liquid nitrogen on campus must be able to vent whether pressurized or non-pressurized. **DO NOT ATTEMPT TO PLUG, REMOVE OR TAMPER WITH ANY PRESSURE RELIEF DEVICE.** Transporting: 1. Liquid Nitrogen Cryogenic Storage Tanks: Larger supply tanks should never be moved on campus unless empty and are equipped with their own wheels. We have a direct delivery and pick-up system, established through stockroom central purchasing, and work closely with the vendor to accommodate the needs of laboratory personnel. Contact the Central Stockroom if an active or full liquid nitrogen tank, already on campus, needs to be relocated. Then, the vendor can be contacted to relocate the larger liquid nitrogen tank(s) using proper carts that are not available on campus. **NEVER ATTEMPT TO TIP, SLIDE OR ROLL CONTAINERS.** 2. Large Liquid Nitrogen Dewars: Large Dewars (> 25L) are secondary storage containers of liquid nitrogen commonly used in laboratories for research purposes. They are often non-pressurized, vacuum-jacketed vessels with loose fitted caps or plugs. This allows for excess pressure to vent while preventing air and moisture from entering. Not all Dewars are rated for liquid nitrogen. Always follow manufacturer guidelines for the use of any cryogenic vessel. Large mobile Dewars transported from area to area must consider the following precautions: 1. A Dewar must be designed for the length and nature of the transport required. Contact the manufacturer for specifications. 2. Never fill a Dewar more than 80% if its capacity. Be aware of the Dewar’s initial temperature prior to filling. A warm Dewar (not currently containing any liquid nitrogen) needs to be filled slowly to reduce temperature shock effects and minimize splashing. ENVIRONMENTAL HEALTH AND RADIATION SAFETY UNIVERSITY OF THE SCIENCES 3. Lifting a Dewars that is not equipped with wheels (> 25 L), when full, is a two person task whether placing the Dewar on a transportation cart or pouring. 4. A large Dewar, equipped with its own wheels, must have wheel diameters greater than 25% of any elevator threshold and/or any other slots/crevasses encountered during transport. Standard Dewar casters, whether welded to its body or not, are not typically meant for transport over pavement, concrete or large areas. A four wheel tipcart or more stable device with appropriate wheels should be used. 5. Steel-toed boots are recommended as Dewars can tip and when full, weigh a considerable amount. 6. Dewars should never be transported in an elevator with any other personnel, including the handler unless a supplied air respirator is in use. Freight elevators should be used when a building is equipped. Whether becoming trapped for a prolonged period of time or the liquid nitrogen begins to boil off at a rapid rate, enough oxygen can quickly become displaced resulting in breathing problems and even death. Elevator Transport Policy: - If a freight elevator is not available, a passenger elevator can be utilized but should be made off limits to all users during the liquid nitrogen’s transport. Place the liquid nitrogen Dewar in the elevator and press the destination floor. Before leaving the elevator post a hazard warning sign on the cylinder to prevent individuals from entering the elevator when the door opens prior to its destination. EXAMPLE: CAUTION –CRYOGENIC LIQUIDS, DO NOT ENTER ELEVATOR - Another handler should be waiting at the designated floor for the receipt and immediate removal of the Dewar. 3. Small Liquid Nitrogen Dewars: The use of small (< 4L) handheld Dewars for transport of liquid nitrogen is permitted throughout a building from room to room, stairwells and elevators. Make sure any and all small Dewars are manufactured for the use of liquid nitrogen and have loose fitted lids or vent. Liquid nitrogen must never be stored or transported in sealed containers. Thermos flasks with tight fitting lids are not suitable even for short periods of time.