som_lab_tension_test

advertisement

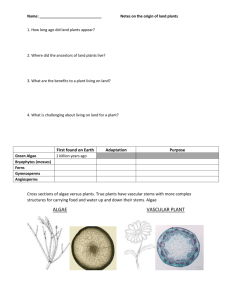

STRENGTH OF MATERIALS MANUAL Students Name Roll Number Experiment No. 01 Title of the Experiment Tension test for ductile and brittle material using extensometer Date of Performance Date of Completion Remarks Signature of staff in charge STRENGTH OF MATERIALS MANUAL EXPERIMENT NO. – 01 AIM:- Tension test for ductile and brittle material using extensometer. APPARATUS:- 1. Universal Testing Machine, 2. Mild steel specimen, 3. Vernier caliper/micrometer, 4. Dial gauge. THEORY:- Various machine and structure components are subjected to tensile loading in numerous applications. For safe design of these components, their ultimate tensile strength and ductility one to be determine before actual use. Tensile test can be conducted on UTM. A material when subjected to a tensile load resists the applied load by developing internal resisting force. These resistances come due to atomic bonding between atoms of the material. The resisting force for unit normal cross-section area is known as stress. The value of stress in material goes on increasing with an increase in applied tensile load, but it has a certain maximum (finite) limit too. The minimum stress, at which a material fails, is called ultimate tensile strength. The end of elastic limit is indicated by the yield point (load). This can be seen during experiment as explained later in procedure with increase in loading beyond elastic limit original cross-section area (Ao) goes on decreasing and finally reduces to its minimum value when the specimen breaks. STRENGTH OF MATERIALS MANUAL UTM & ITS SPECIFICATIONS:- The tensile test is conducted on UTM. It is hydraulically operates a pump, oil inoil sump, load dial indicator and central buttons. The left has upper, middle and lower cross heads i.e. specimen grips (or jaws). Idle cross head can be moved up and down for adjustment. The pipes connecting the lift and right parts are oil pipes through which the pumped oil under pressure flows on left parts to more the crossheads. STRENGTH OF MATERIALS MANUAL SPECIFICATIONS:- 1. Load capacity = 2. Least count = 3. Overall dimension. = 4. Power supply = STRENGTH OF MATERIALS MANUAL PROCEDURE:- 1. The load pointer is set at zero by adjusting the initial setting knob. 2. The dial gauge is fixed and the specimen for measuring elongation of small amounts. 3. Measuring the diameter of the test piece by vernier caliper at least at three places and determine the mean value also mark the gauge length. 4. Now the specimen is gripped between upper and middle cross head jaws of the m/c. 5. Set the automatic graph recording system. 6. Start the m/c and take the reading. 7. The specimen is loaded gradually and the elongation is noted until the specimen breaks. SPECIMEN - DUCTILE MATERIAL OBSERVATIONS:- i. Initial diameter of specimen d1 = ------ ii. Initial gauge length of specimen L1 = ----- iii. Initial cross-section area of specimen A1 = ---- iv. Load of yield point Ft. = ----- v. Ultimate load after specimen breaking F = ----- vi. Final length after specimen breaking L2 = ------ vii. Dia. Of specimen at breaking place d2 = ------- viii. Cross section area at breaking place A2 = ---- CALCULATION:- a) Ultimate tensile strength = -----b) Percentage elongation % = ----- STRENGTH OF MATERIALS MANUAL c) Yield stress = -------d) % reduction in area = ------- SPECIMEN - BRITTLE MATERIAL OBSERVATIONS:- ix. Initial diameter of specimen d1 = ------ x. Initial gauge length of specimen L1 = ----- xi. Initial cross-section area of specimen A1 = ---- xii. Ultimate load after specimen breaking F = ----- xiii. Final length after specimen breaking L2 = ------ xiv. Dia. Of specimen at breaking place d2 = ------- xv. Cross section area at breaking place A2 = ---- CALCULATION:- a) Ultimate tensile strength = -----b) Percentage elongation % = ----c) % reduction in area = ------- PRECAUTIONS:- 1. The specimen should be prepared in proper dimensions. 2. The specimen should be properly to get between the jaws. 3. Take reading carefully. 4. After breaking specimen stop to m/c. RESULT:- 1. The modulus of elasticity of _ _ _ _ _ _ _ _ is ------2. The modulus of elasticity of _ _ _ _ _ _ _ _ is ------- STRENGTH OF MATERIALS MANUAL Tension Test 1. Select the proper jaws to suit the sample to be tested and complete the jaw assemblies with the middle and upper crossbeam. Apply some graphite grease (mixture of flaked graphite and grease) to the tapered surface of the grip for smooth motion. 2. Operate the upper beam jaw handle and hold the specimen tightly. 3. Keep both the right side and left side valves in fully closed condition. 4. Start the hydraulic motor. Open the right side valve slowly. This will lift lower beam slightly. Keep the right side valve slightly open such that lower beam is slowly moving upwards. 5. Go to test mode on electronic panel/display. 6. Now, tare the reading to zero (this will compensate for the dead weights of lower and upper beam assembly.) 7. Operate the geared motor and adjust the up/down position of middle beam to suit the proper clamping of test piece. 8. Operate the jaw handle of middle beam to clamp the lower portion of specimen. Lock the jaws in this position by operating the jaw lock handle. 9. Do not tare the load even if it changes from zero. 10.Turn the right control valve slowly to open position (i.e. anticlockwise) till you get a desired loading rate. Stop further turning of valve once the rate is set. 11. After rupture of specimen stop the pump motor. Close the right control valve and remove the broken pieces of test piece & then operate left control valve to take down the piston. Additional Points for Tension Test:1. Grip the specimen for the whole length of the inserts Do not hold less than the length of inserts. This may damage the teeth of the jaws, pinion & inserts, as well as a serious damage to cross Head surface. STRENGTH OF MATERIALS MANUAL 2. After the rupture of specimen, if the specimen gets locked inside the jaws, do not hammer the handles, instead hammer the ruptured specimens. 3. During tensile testing of specimen, if electricity fails discard the test specimen by cutting it into two pieces. Then remove the locked specimen by hammering on it. 4. As a precaution, unlock the locking the handle after the specimen got clamped in the jaws. The load indicator will indicate the increase of load, i.e. locking of the specimen due to wedge action and locking handle is no more required. 5. Gripping length should be uniform in cross section. Do not grip the bent/damaged ends of the specimen. 6. Remove handles from both upper and middle crosshead while testing a tensile specimen. When the specimen fails all of a sudden, handles are likely to fly or fall down due to jerk. This may injure operator or other machine parts. 7. Ensure the upper crosshead cover is clamped firmly by screws on upper crosshead cover. This is especially important for high capacity machines(say 600KN and above) while testing TMT or high strength high load bars, in tension, due to heavy jerk at the time of specimen failure, the upper cross head cover screws may get loosened after few tests. It is dangerous if the upper crosshead cover screws may get sheared & the cover flies away causing accident. 8. Cleaning of inserts- while conducting tensile test the inserts grip the specimen. For many specimens the loose particles or flakes get deposited in the serrations of the insert. It is necessary to clean up the inserts with the help of the cleaning brush applied with tensile load. 9. Grease should be applied on the rear face jaws- it is a must to apply a grease with solid lubricant on the crosshead taper faces and on the taper rear faces of the jaws. This ensures easy sliding of jaws along the faces of the crossheads there by facilitating perfect gripping. 10.Recommended lubricant – OKS MOS Assembly paste. STRENGTH OF MATERIALS MANUAL Technical Specifications 1. Model : 2. Maximum capacity : 3. Clearance for tensile test at fully descended working piston : 4. Clearance for compression test : 5. Clearance between columns : 6. Ram stroke : 7. Power supply: 8. Oil Pump : 9. Output of pump : 10.H.P. Motor for pump : 11.H. P. of Motor for middle beam : 12.Overall dimensions of machine (mm) (L x W x H) 13.Approximately Weight :