Teaching Labs Chemistry

advertisement

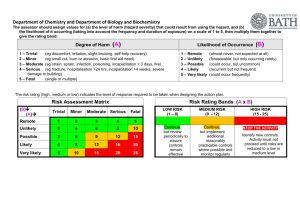

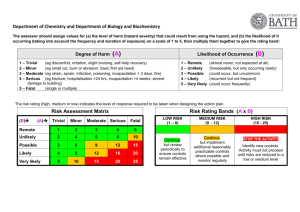

Department of Chemistry and Department of Biology and Biochemistry The assessor should assign values for (a) the level of harm (hazard severity) that could result from using the hazard, and (b) the likelihood of it occurring (taking into account the frequency and duration of exposure) on a scale of 1 to 5, then multiply them together to give the rating band: Degree of Harm (A) Likelihood of Occurrence 1 – Trivial (eg discomfort, irritation, slight bruising, self-help recovery) 2 – Minor (eg small cut, burn or abrasion, basic first aid need) 3 – Moderate (eg strain, sprain, infection, poisoning, incapacitation > 3 days, fire) 4 – Serious (eg fracture, hospitalisation >24 hrs, incapacitation >4 weeks, severe damage to building) 5 – Fatal (single or multiple) 1 – Remote 2 – Unlikely 3 – Possible 4 – Likely 5 – Very likely (B) (almost never, not expected at all) (foreseeable, but only occurring rarely) (could occur, but uncommon) (recurrent but not frequent) (could occur frequently) The risk rating (high, medium or low) indicates the level of response required to be taken when designing the action plan. Risk Assessment Matrix (B) (A) Risk Rating Bands (A x B) Trivial Minor Moderate Serious Fatal Remote 1 2 3 4 5 Unlikely 2 4 6 8 10 Possible 3 6 9 12 15 Likely 4 8 12 16 20 Very likely 5 10 15 20 25 LOW RISK (1 – 8) MEDIUM RISK (9 - 12) Continue, but review periodically to ensure controls remain effective Continue, but implement additional reasonably practicable controls where possible and monitor regularly HIGH RISK (15 - 25) STOP THE ACTIVITY Identify new controls. Activity must not proceed until risks are reduced to a low or medium level Risk Assessment of: Working in the Chemistry Teaching Labs Overview of activity / location / equipment / conditions being assessed: Assessor(s): Marianne Harkins & Robyn Bott Work Authorised by: Date: July 2015 A risk assessment of work in the Chemistry Department teaching laboratories (3S 0.09 and 1.05), covering the types of general hazards that may be encountered as part of teaching practicals. Good Laboratory Practice Anyone working in the teaching laboratories will have a health and safety induction. Instructions should be listened to and followed. Avoid hand to mouth/eye/face contact and thoroughly wash your hands before leaving the lab. Do not eat, drink, smoke, apply cosmetics or manipulate contact lenses in the laboratories. There are properly functioning safety showers in the laboratory – please familiarise yourselves with their location. All work with hazardous substances must have a risk assessment; this may be a short COSHH version. Students must be aware of their own limitations, and seek assistance from a member of staff/ technical expert if required (preferably before commencing work). All staff and students are responsible for their own and others safety (either directly, or though acts of omission), and all have the authority to stop work they perceive as unsafe. Individuals must be aware of the limitations of the disposable nitrile gloves with solvents, as in some cases the gloves afford only splash protection. Any accidents must be reported to academic staff, the technical team or demonstrators as soon as possible. In the event of a fire, experiments will be stopped and/ or made safe if there is time to do so without endangering life and staff will follow instructions. Spills will be cleared as soon as possible, while the contaminant is known, and not allowed to accumulate. This is particularly important when using balances. Individuals are responsible for clearing up experiments, preventing the build-up of rubbish/ cardboard, and for keeping exits clear. Waste generated by lab users must be properly contained, labelled, and with a clean exterior before being transferred to the waste consignor for disposal by the technical team. Personal Protective Equipment As a minimum a lab coat and safety glasses should be worn in the lab at all times. Any PPE specified for working with specific chemicals should be worn/ used. Closed footwear with good grip will be worn in the lab, (i.e., no exposed skin/ socks, no open-toed footwear/ sandals). Loose clothing (e.g. scarves, ties) must be securely tucked behind lab coats or removed. Long hair must be tied back. Hazard Who could be harmed? Control measures needed to minimise risk Exposure to Chemicals Depending on the hazard category, there are a wide range of possible effects from exposure to chemicals: skin and eye irritation/ corrosion/ permeation. Tissue damage of mucous membranes/ respiratory tract, dermatitis from prolonged or repeated skin exposure and in severe cases central nervous system depression or organ effects. Unconsciousness and even death can result from exposure to some hazardous chemicals. Laboratory users, staff, support staff, PG and UG students, contractors and/ or visitors to the laboratory. Exposure to acids and bases Skin and eye irritation/ corrosion/ permeation. Tissue damage of mucous membranes/ respiratory tract, dermatitis from prolonged or repeated skin exposure and in severe cases central All chemicals must be COSHH assessed prior to starting work. Students should clearly follow the COSHH assessment in their lab manual and follow verbal instructions clearly. Chemicals are to be clearly labelled and stored in a well ventilated area away from direct sunlight and heat, in accordance with the supplier’s recommendations, and returned to storage after use. Decanted materials must not be returned to the bulk container. Staff should ensure that any flammables are stored in a flammables cabinet. Ensure that a spill kit is available. Staff should ensure that different types of chemical waste should be listed and segregated in to categories before passing on the hazardous waste technician. Staff should ensure that chemicals should be listed and boxed and moved to the hazardous waste compound on a regular basis. Dispense flammable liquids and chemicals, and use them, in a place where there is good ventilation and no source of ignition. Keep containers closed when not in use. Keep some non-flammable absorbent material handy to mop up spills. Keep the working area dust-free from flammable dusts by regular cleaning, and dealing with spillages as they occur. Staff are to store flammable liquids and chemicals in a flammables cupboard. Avoid breathing the gas or fumes from acid or base solutions. If COSHH assessment specifies use a fume cupboard. Ensure that you know the location of a spill kit before working with corrosive materials. Ensure that you know the location of your nearest eyewash station. Always add the acid to the water (and not vice versa, as a violent reaction may result). Emergency procedures: Flush affected area with copious water and summon medical attention immediately (x666) Risk after controls implemented A B AxB nervous system depression or organ effects. Eye Contact: In case of contact, immediately flush eyes with plenty of water for at least 15 minutes. Cold water may be used. Check for and remove (if possible) any contact lenses. Skin Contact: In case of contact, immediately flush skin with plenty of water for at least 15 minutes while removing contaminated clothing and shoes. Cold water may be used. Wash clothing before reuse. Thoroughly clean shoes before reuse. Inhalation: If inhaled, remove to fresh air. If not breathing, give artificial respiration (using bag and mask, or first aider will also suffer inhalation effects). If breathing is difficult, give oxygen. WARNING: It may be hazardous to the person providing aid to give mouth-to-mouth resuscitation when the inhaled material is toxic, infectious or corrosive. Ingestion: If swallowed, do not induce vomiting unless directed to do so by medical personnel. Never give anything by mouth to an unconscious person. Loosen tight clothing such as a collar, tie, belt or waistband. Exposure to solvents Irritation of eyes/ respiratory system/skin. Headache, nausea, dizziness. Co-ordination may become impaired, which may increase your chance of having an accident. Unconsciousness and even death can result from exposure to high concentrations of solvent vapours. Spills Exposure to any of the chemicals listed above. Inform an academic, demonstrator or member of the technical team that you have had a spill. Spills are to be cleaned up as a priority, wearing the correct PPE. Spill kits are available. Safety showers, eye washes and running water are available in the laboratories for any bodily contact. Sharps Puncture wounds/ scrapes/ infection. Dispose of broken glass in designated glass bins. Always use a dustpan and brush to clear up any breakages. Let the technical team know of any breakages. Make the most of natural ventilation, where appropriate, by opening doors and windows and use fume hoods where appropriate. Prevent unnecessary evaporation of solvents by using the minimum amount for the job, keeping lids on containers and using sealed containers for solvent-contaminated waste. Do not leave solvent-contaminated rags/ blue roll/ tissue lying around. Dispose of them in waste containers. See technical staff if you are unsure which containers to use. Re-sheathing of hypodermic needles is prohibited. If hypodermic needles are contaminated with hazardous materials extreme care must be taken during usage. Used sharps must be disposed of in designated sharps bins immediately after use. No sharps will be left uncontained when not in use, e.g., store covered, or in holder. When handling blades, the correct handles/ attachments will be used at all times. Training/ mentoring will be given for working with sharps. Analytical syringe needles that are routinely re-used must be stoppered on the end when not in use, e.g., stuck in cork ring or similar. Instrumentation Puncture wounds/ trap wounds/ scrapes/ infection/ electric shock/ burns. All instrumentation will be PAT tested. Always follow instructions carefully. Do not remove any of the safety guards on instrumentation. If in doubt, ask your demonstrator or a member of the technical team for assistance. Always use the correct consumables. If defect or damages are observed, do not use the instrument and inform a member of staff. Electrical equipment/ installations Electric shock All portable electrical equipment must be tested for electrical safety at correct intervals Electrical cables and plugs should be regularly visually inspected by the user for damage. Any defective equipment should be reported to the technician-in-charge and taken out of use until the repair has been effected. Electrical equipment must always be operated in accordance with manufacturers' instructions Biological Contamination of person or the environment resulting in illness, infection or disease. Unauthorised access to facility Access to the laboratories is restricted. Visitors should be accompanied by an approved person. All doors should be locked when personnel are not present in the facility. Gas cylinders Undergraduate students are not permitted to use gas cylinders. Staff and demonstrators must have received Gas Safety Training before using gas cylinders. Contact the technical team to arrange training. All work with biologicals must be COSHH assessed before work starts. Biological/ contaminated and GM waste will be autoclaved, and will be placed in autoclave bags. All waste to be autoclaved is to be taken to the 3 South autoclave room (double bagged and transported within the boxes). Fire/ Explosion Burns/ smoke inhalation or death. Damage or loss of infrastructure. Flammable materials are stored in the flammables cupboard in the back store. Benching is to be kept free of clutter. Fire extinguishers are available in the laboratory. There is also one available outside. Only trained personnel should use the extinguishers. All unnecessary ignition sources must be removed. Call security on 666 (internal) or 01225 383999 (external) in an emergency. Slips and Trips Slipping on floors/ tripping on hazards See housekeeping practices below. Floors are regularly swept to keep them clean. Good housekeeping means that clutter is removed. A waste management technician is employed to ensure best practice. Manual Handling Musculoskeletal problems. Do not lift heavy and bulky loads. If you do not feel able to lift safely, please let a technician, demonstrator or member of academic staff know. The University Manual Handling Procedures must be followed by staff who undertake the lifting of heavy loads. http://www.bath.ac.uk/hr/stayingsafewell/health-wellbeing/manual-handling/index.html Emergency Procedures In the event of a fire evacuate the lab as quickly as possible and set off the fire alarm (to ensure the rest of the building is also evacuated). Call the security team (666 internal and 0.1125 383999 external) and ensure that the fire services are aware that there is a fire in a chemical laboratory. Housekeeping Practices General lab cleaning (benches and floors): Will be completed using commercially available cleaning products, and undertaken only in areas where lab-work is not in progress. A floor buffer or mop and bucket may be used for floor cleaning, and the floor must be as dry as reasonably practicable during and after the cleaning process. Warning signs must be posted at entrances to the lab when the floor is being cleaned. Glass-washers: Glassware must be rinsed by the user (washings into a waste bottle) before being put through the glass-washer. Items too large or fragile to go through the machine must be washed by hand. Items will usually be cleaned using detergent, rinsing with water and/ or rinsing with solvent where appropriate. Larger items will be wiped down using the above process. For some items of apparatus (especially glassware), an acid rinse (e.g., dilute nitric acid) may be required if the water, detergent and solvent are ineffective. Fume Cupboards: Where the fume cupboard is to be cleaned prior to maintenance work, the interior of the cupboard (including the sash) will be washed down with detergent (e.g., Decon 90, diluted in accordance with manufacturer’s instructions) and rinsed with water. Any smears may be removed using a solvent (e.g., isopropanol). Spraying equipment or tubing attached to the water supply may be used to wash down behind the baffles at the back of the cupboard. Equipment for Servicing/ Calibration/ Disposal: Lab equipment is to be cleaned as far as possible, wiping over with detergent and water, and solvent, although the electronics/ internal workings will not be cleaned. The equipment is left to air to minimise any vapour hazard that may be in areas impossible to decontaminate with solution.