Rainwater harvesting can (a) assure an independent water supply

advertisement

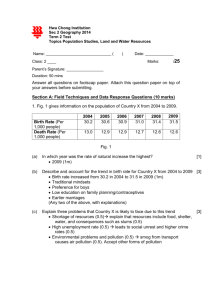

One of the primary requirements of a water harvesting system is that of containers to store the harvested water in a hygienic condition. This need is more pronounced in high-rainfall areas, where it is more feasible to store water in containers for direct use, rather than for recharging the groundwater. Generally, in small domestic systems, the cost of constructing tanks with conventional materials like masonry or RCC is far more than that of the rainwater collection and piping component. Ferrocement can provide a lowcost and easy-to-build solution to the need for low-cost containers. This technology is particularly relevant for regions like Meghalaya, Arunachal Pradesh and Kerala, which have high frequency of rainfall. Ferrocement Fundamentals Ferrocement consists of a thin sheet of cement mortar which is reinforced with a cage made of wire mesh and steel bars. Because ferrocement is structurally more effectient than masonry, the thickness of the walls of the container are as low as 10 to 15 mm. Ferrocement components can be casted in any shape using suitable mouolds. The technology is extremely simple to implement, and even semi-skilled workpersons can learn it with ease. Ferrocement requires only a few easily available materials - cement, sand, galvanized iron (GI) wire mesh, and mild steel (MS) bars - in small amounts compared to masonry and RCC. The Structural Engineering Research Centre (SERC), Ghaziabad, has done research and development on a large number of low-cost structures and implements like water/grain storage containers, irrigation channels, biogas digesters and septic tanks, primarily using ferrocement. SERC scientists are imparting training in ferrocement technology to rural artisans under the National Drinking Water Mission. Ferrocement containers can be used to store grain and seed, apart from water. Tanks of 1000-2000 litre capacity can be constructed with ease, which are much cheaper than masonry, RCC or plastic tanks. These are easy to repair, and can be easily transported because of their sturdy nature. Such containers have been used on a wide scale since about the past 25 years in Thailand, Malaysia and some African countries. Ferrocement containers with capacity as much as 5000 litres have been constructed in Thailand. The process of building a ferrocement container is very simple which users can do themselves, with some training. For a typical circular pot-shaped container, the only materials required are hessian cloth, chaff (waste from agricultural produce), GI wire mesh, MS bars, cement and sand. To prepare the mould, the hessian cloth, stitched into a sack resembling the shape of the container, is filled with chaff that is compacted in layers. Dry leaves or dry grass can be used in place of chaff. Once the sack is filled with the filler material, it is beaten into the required shape by a wooden bat. A GI wire mesh (22-26 guage - see Table 1) is tied around the mould leaving sockets at suitable locations for inlet, overflow and cleaning pipes. Tying 6 mm diameter mild steel (MS) bars at wide intervals both horizontally and vertically strengthens the reinforcement cage. Table 1: Parameters for various capacities of ferrocement containers CapacityThickness (ltrs) of walls (mm) Ratio cement:sand Thickness of GI wire (guage) 400 10 1:3 26 600 10 1:3 24 900 12 1:2.5 24 1500 15 1:2.5 22 Once the reinforcement cage is tied, cement mortar having cement-sand proportion of 1:2.5 or 1:3 (see Table 1) is prepared, having water content equal to 0.45 times the volume of cement. The mortar is plastered in two layers along the wall thickness, the second layer being applied 24 hours after the first. The ferrocement wall normally has a thickness of 10 to 15 mm, depending on the volume of the container (see Table 1). The cement mortar is applied ensuring a minimum clearance (cover) of 3 mm between the reinforcement mesh and the outer surfaces of the wall. The mould of the container is removed 24 hours after casting of the walls is completed, by removing the filler material, and the container can be brought into use after 10 days of wet curing. SERC has developed large capacity ferrocement rooftop water collectors of upto 10,000 litres. KUNDS In the sandier tracts, the villagers of the Thar Desert had evolved an ingenious system of rainwater harvesting known as kundsor kundis. Kund, the local name given to a covered underground tank, was developed primarily for tackling drinking water problems. Usually constructed with local materials or cement, kundswere more prevalent in the western arid regions of Rajasthan, and in areas where the limited groundwater available is moderate to highly saline. Groundwater in Barmer, for instance, in nearly 76 per cent of the district’s area, has total dissolved salts (TDS) ranging from 1,50010,000 parts per million (ppm). Under such conditions, kunds provided convenient, clean and sweetwater for drinking. Before the onset of rains every year, meticulous care was taken to clean up the catchment of the kunds. Cattle grazing and entry with shoes into the catchment area of the kundswas strictly prohibited. The proximity of a kund to the house or village saved time and effort in searching for drinking water. Without a kund, households in many parts of the Thar would have to make a 10-15 km round trip with a donkey, camel or bullock cart to meet their water needs. Coupled with the benefits of cleanliness and quality of water, the kund became an ideal device to collect drinking water. Water-borne diseases, which are otherwise quite common in the desert area, are thus reduced. The kund consists of a saucer-shaped catchment area with a gentle slope towards the centre where a tank is situated. Openings or inlets for water to go into the tank are usually guarded by a wire mesh to prevent the entry of floating debris, birds and reptiles. The top is usually covered with a lid from where water can be drawn out with a bucket. Kunds are by and large circular in shape, with little variation between the depth and diameter which ranges from 3-4.5 m. Lime plaster or cement is typically used for the construction of the tank, since stone as a building material is not always available and is relatively more expensive. Either of these materials can be used to plaster the horizontal and vertical soil surfaces, although cement ensures a longer life span. The success of a kund depends on the selection of the site, particularly its catchment characteristics. An adequately large catchment area has to be selected or artificially prepared to produce adequate runoff to meet the storage requirements of the kund. The catchment size of kunds varies from about 20 sq m to 2 ha depending on the runoff needed and the availability of spare land. A 2 ha catchment area, having a 2-3 per cent slope on a heavy textured soil free from vegetation, is generally sufficient for a kund of 200 cubic metres (cum) capacity. The catchment areas of kunds were made in a variety of ways using locally available sealing materials such as pond silt, murrum, charcoal ash, and gravel. After clearing the soil surface of vegetation, the land was given a smooth gradient of 3-4 per cent towards the kund and the cleared surface was lined with pond silt obtained from nearby talabs or nadi beds. A local technique was used after the first shower of the monsoon season to make this layer semipermeable. In places where a calcium-carbonate zone was available below the soil surface at a shallow depth, water-proofing of the soil was done with murrum. After clearing the soil surface of vegetation, a thin layer ofmurrum was spread over it. With the onset of the monsoon, sheep and goats were made to move over themurrum repeatedly till the surface was compacted and became semi-impermeable. During this process water was also sprinkled, if needed. Although charcoal ash was not used as a surface sealing material by itself, it was used to repair the catchment area made of pond silt and murrum. As the ash settled down, it filled the pores making the surface water-proof. In certain areas, where rock exposures occurred, kund catchments were made of gravel layers. Such catchments were, however, very few, depending on the availability of gravel. The benefits of kunds during inadequate rainfall have been in doubt. However, a study which analysed daily rainfall records for 14 years in three or four raingauge stations in each of the 11 desert districts of Rajasthan puts these doubts to rest. It was calculated that there was effective rainfall (25 mm) on at least four to six days every year, except in Jaisalmer, Pali and Sikar. With this rainfall, a kund with a catchment of 100 sq km could easily collect 10,000 litres of water.Kunds with a diameter of 56 m and a catchment area of 2,463 sq m will bring in 246,000 litres of water. Even if we assume that only 40-50 per cent of rain will turn into runoff, a kund can still store 0.1 million litres of water. The rainfall data collected showed that areas with 100 mm of rainfall can use the kundsystem effectively. Even if the kunds do not collect sufficient water they can be used as water reservoirs which can be filled by transporting water through water tankers. At present, tankers remain in the village till such time as the villagers have filled their pitchers, making numerous trips and losing a lot of time in the process. By filling the kunds, the tankers would need to make fewer trips as the entirekund could be filled up at one go. More Harvesting Systems Ground catchment systems Ground catchments systems channel water from a prepared catchment area into storage. Generally they are only considered in areas where rainwater is very scarce and other sources of water are not available. They are more suited to small communities than individual families. If properly designed, ground catchment systems can collect large quantities of rainwater. Rainwater harvesting systems channel rainwater that falls on to a roof into storage via a system of gutters and pipes. The first flush of rainwater after a dry season should be allowed to run to waste as it will be contaminated with dust, bird droppings etc. Roof gutters should have sufficient incline to avoid standing water. They must be strong enough, and large enough to carry peak flows. Storage tanks should be covered to prevent mosquito breeding and to reduce evaporation losses, contamination and algal growth. Rainwater harvesting systems require regular maintenance and cleaning to keep the system hygienic. [edit]Subsurface dyke A subsurface dyke is built in an aquifer to obstruct the natural flow of groundwater, thereby raising the groundwater level and increasing the amount of water stored in the aquifer. The subsurface dyke at Krishi Vigyan Kendra, Kannur under Kerala Agricultural University with the support ofICAR, has become an effective method for ground water conservation by means of rain water harvesting technologies. The sub-surface dyke has demonstrated that it is a feasible method for conserving and exploiting the groundwater resources of the Kerala state of India. The dyke is now the largest rainwater harvesting system in that region. [edit]Groundwater recharge Rainwater may also be used for groundwater recharge, where the runoff on the ground is collected and allowed to be absorbed, adding to the groundwater. In the US, rooftop rainwater is collected and stored insump.[2] In India this includes Bawdis and johads, or ponds which collect the run-off from small streams in wide area.[3][4] In India, reservoirs called tankas were used to store water; typically they were shallow with mud walls. Ancient tankas still exist in some places.[4] [edit]Advantages in urban areas Rainwater harvesting can (a) assure an independent water supply during water restrictions, that is though somewhat dependent on end use and maintenance, (b)usually of acceptable quality for household needs and (c) renewable at acceptable volumes despite forecast climate change (CSIRO, 2003). It produces beneficial externalities by reducing peak stormwater run off and processing costs. RH systems are simple to install and operate. Running costs are negligible, and they provide water at the point of consumption.We are consuming this water for our basic needs. Rainwater harvesting can be adopted in cities to supplement the city's other water supplies, to increase soil moisture levels for urban greenery, to raise the water table through artificial recharge, to mitigate urban flooding and to improve the quality of groundwater. In urban areas of the developed world, at a household level, non-potable uses of harvested rainwater include bathroom (i.e. shower/bath/basin), flushing toilets and washing laundry. Indeed in hard water areas it is superior to municipal water for laundry because of its compatibility with detergents and soaps. Rainwater may require treatment prior to use for drinking, depending on anthropogenic (e.g. vehicle exhaust) and natural (e.g. Coal.) contaminants. In New Zealand, many houses away from the larger towns and cities routinely rely on rainwater collected from roofs as the only source of water for all household activities. This is almost inevitably the case for many holiday homes. [edit]Quality As rainwater may be contaminated, it is often not considered suitable for drinking without treatment. However, there are many examples of rainwater being used for all purposes — including drinking — following suitable treatment. Rainwater harvested from roofs can contain animal and bird faeces, mosses and lichens, windblown dust, particulates from urban pollution, pesticides, and inorganic ions from the sea (Ca, Mg, Na, K,Cl, SO4), and dissolved gases (CO2, NOx, SOx). High levels of pesticide have been found in rainwater in Europe with the highest concentrations occurring in the first rain immediately after a dry spell;[5]the concentration of these and other contaminants are reduced significantly by diverting the initial flow of water to waste as described above. The water may need to be analysed properly, and used in a way appropriate to its safety. In the Gansu province for example, harvested rainwater is boiled in parabolic solar cookers before being used for drinking.[6] In Brazil alum and chlorine is added to disinfect water before consumption.[citation needed] So-called "appropriate technology" methods, such as solar water disinfection, provide low-cost disinfection options for treatment of stored rainwater for drinking. [edit]System sizing It is important that the system is sized to meet the water demand throughout the dry season. Generally speaking, the size of the storage tank should be big enough to meet the daily water requirement throughout the dry season. In addition, the size of the catchment area or roof should be large enough to fill the tank.