polb23923-sup-0001-suppinfo01

advertisement

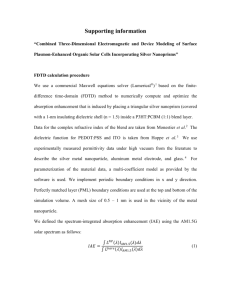

Supporting Information Structures of Poly(3-hexylthiophene) Films Prepared from Binary Solvent Mixtures Lawson T. Lloyd, Madeleine P. Gordon, David S. Boucher Department of Chemistry and Biochemistry, School of Sciences and Mathematics, College of Charleston, Charleston, South Carolina 29424 Supplementary UV/Vis Absorbance Spectra FIGURE S1 Normalized UV/Vis absorbance spectra of (a) low molecular weight (L-Mw) and (b) high molecular weight (H-Mw) P3HT in the 40:60 CF:HEX solvent mixture. Each panel shows the spectrum for aged 0.1 mg·mL– 1 , and 0.3 mg·mL–1 dispersions. 1 FIGURE S2 Normalized UV/Vis absorbance spectra of (a) low molecular weight (L-Mw) and (b) high molecular weight (H-Mw) P3HT in the 30:70 CF:AcN solvent mixture. Each panel shows the spectrum for aged 0.1 mg·mL – 1 , and 0.3 mg·mL–1 dispersions. 2 Extracting the Aggregate Spectrum FIGURE S3 Method used to extract the aggregate absorbance spectrum (–––) by removing the scaled amorphous contribution from (---) from the raw absorbance spectrum (–––). The procedure is taken from ref. 1. Determining the Extent of Aggregation1 This method assumes that there are only two species in the dispersion: a residual, non-aggregated amorphous phase and the P3HT aggregates. The absorbance of the residual amorphous P3HT phase is approximated by scaling the raw amorphous spectrum (recorded at the same concentration as the dispersion, e.g., 0.1 mg·mL–1) to the high energy edge of the dispersion spectrum (Figure SX). As shown in Figure SX, the aggregate absorbance spectrum is extracted by removing the scaled amorphous spectrum from the spectrum of the P3HT dispersion. The area under the aggregate spectrum, , ΔAaggregate, (the cross-hatched region in Figure SXX) is a measure of the oscillator strength of the P3HT aggregates. Similarly, the difference between the raw and scaled amorphous P3HT spectra, ΔAamorphous, (the gray area in Figure SXX) reflects the change in the amorphous phase oscillator strength. The relative oscillator strength, F, of the amorphous and aggregate phases in the dispersion is given by the ratio, 𝐹 =– ∆𝐴𝐴𝑔𝑔𝑟𝑒𝑔𝑎𝑡𝑒 ∆𝐴𝐴𝑚𝑜𝑟𝑝ℎ𝑜𝑢𝑠 which, in turn, is related to the molar extinction coefficients (), 𝐹= 𝐴𝑔𝑔𝑟𝑒𝑔𝑎𝑡𝑒 𝐴𝑚𝑜𝑟𝑝ℎ𝑜𝑢𝑠 Because all of the P3HT chains removed from the amorphous phase are incorporated into the aggregate phase, once the relative oscillator strength is calculated the fraction of aggregated P3HT is obtained from the absorbance spectra of the amorphous and aggregate phases. 3 FIGURE S4 Method used to estimate the extent of aggregation of P3HT. The area under the aggregate absorbance curve, ΔAaggregate, (cross-hatched) and the difference between the raw and scaled amorphous P3HT spectra, ΔAamorphous, (gray area) are a measure of the relative oscillator strengths of the amorphous and aggregate components. TABLE S1 Relative Oscillator Strength, F,and Fraction of Aggregates P3HT F %Agg 20:80 (v%:v%) CF:DCM L-Mw 1.50 42 H-Mw 1.50 57 40:60 (v%:v%) CF:HEX L-Mw 1.53 46 H-Mw 1.60 58 30:70 (v%:v%) CF:AcN L-Mw 1.36 58 H-Mw 1.49 60 4 Dynamic Light Scattering FIGURE S5 DLS particle size distributions of amorphous H-Mw and L-Mw P3HT in chloroform. 5 Thermodynamic Equilibrium and the Impact of Solution Preparation The methods used to prepare P3HT dispersions affects their properties, e.g., excitonic coupling values and extent of aggregation.2 To assess the impact of different preparation techniques on the assemblies in our solvent mixtures, we prepared L-Mw and H-Mw samples in CF:HEX and CF:DCM by sonicating 0.1 mg·mL– 1 dispersions for 4 minutes prior to aging for 24 hours. We chose to use sonication because several groups have shown that this method improves the yield and structural order of assembled P3HT nanofibers in pure solvents.3-5 To our knowledge the effect of sonication on P3HT assembly in solvent mixtures has not been investigated. In addition to sonication, we prepared a 0.1 mg·mL–1 dispersion of L-Mw P3HT in 20:80 CF:DCM by adding the DCM slowly over a 24 hour period via an automated syringe pump. We measured the UV/Vis spectra after 24 hours and then again 1 week later. The excitonic coupling values are given in Table S2. TABLE S2 Excitonic Coupling Values Using Different Dispersion Preparation Methods J (L-Mw) J (H-Mw) [meV] [meV] 20:80 (v%:v%) CF:DCM Aged (24 hr) 11 11 Aged (1 week) 11 11 Slow DCM Add (24 hr) 6 --Slow DCM Add (1 week) 8 --Sonicated (24 hr) 9 8 Sonicated (1 week) 9 8 40:60 (v%:v%) CF:HEX Aged (24 hr) 10 10 Aged (1 week) 11 11 Sonicated (24 hr) 11 12 Sonicated (1 week) 12 13 System After 24 hours the excitonic coupling values of the sonicated dispersions in CF:HEX are slightly larger than the non-sonicated sample. The increase for L-Mw P3HT is on the edge of 1 meV error bar. However, for these studies we are using aliquots of the same solution aged for 1 week, i.e., with no further dilution, so we believe that a 1 meV change is significant. After one week of aging the J values of the non-sonicated and sonicated dispersions increase by 1 meV, which contrasts with the behavior of the CF:DCM dispersions. In CF:DCM the excitonic coupling values of the sonicated dispersions are slightly smaller than those prepared without sonication. For both of these methods the J values are do change by 1 meV after one week of aging. The dispersion prepared by slow addition of DCM exhibits a 6 meV J value after 24 hours, and this value increases to 8 meV after one week of aging. These excitonic coupling values are significantly lower than the 11 meV values obtained for solutions prepared by rapid addition of DCM and, as show in Figure S6, the lower J values can be rationalized based on the large amount of amorphous P3HT left in these solution. Our analysis estimates that the extent of aggregation is 20% and 30% in these dispersions and as the amorphous phase decreases, the J values increase, which is consistent with chain fractionation arguments. It is notable that the slow addition of the DCM solvent gives rise to a larger change in the extent of aggregation over an additional one week aging period. Based on these observations and results of our previous work,6 solvent mixtures containing DCM may prove extremely useful to monitor the real-time assembly and crystallization of P3HT in the liquid phase. 6 FIGURE S6 UV/Vis absorbance spectra of low molecular weight (L-Mw) P3HT dispersions (0.1 mg·mL–1) in a 20:80 CF:DCM solvent mixture. The spectra are normalized to an approximate isosbestic point at 510 nm. The solid (—) spectrum shows the absorbance of dispersions made following the slow addition of DCM over a period of 24 hours. The dotted (·····) spectrum is the same dispersion that was left to age for 1 week. The dashed spectrum (----) is corresponds to a dispersion prepared by rapid addition of DCM and a 24 hour aging time, i.e., the same as in Figure 1(a). Confocal Microscopy FIGURE S7 Optical micrograph of H-Mw P3HT films cast from the same 0.1 mg·mL–1 dispersion and dried under (a) slow and (b) rapid evaporation conditions. The images were taken using a 10× (NA = 0.3) objective. The tapping mode AFM image (25 μm × 25 μm) of (b) is shown in Figure S8. 7 Additional Atomic Force Microscopy Images FIGURE S8 Tapping mode AFM image (25 μm × 25 μm) of H-Mw P3HT drop cast from pure chloroform and dried under rapid evaporation conditions. FIGURE S9 Tapping mode AFM image of L-Mw P3HT drop cast from 30:70 CF:AcN and dried under slow evaporation conditions that shows the extent and density of the dot-like structures across a larger (20 μm×20 μm) region. Honeycomb Pattern of Films Cast from 20:80 CF:DCM Marangoni Effects Marangoni instabilities arise due to surface tension and/or viscosity gradients in the evaporating polymer solution. The viscosity (η) and surface tension (σ) of chloroform (σ = 27.2 dyne·cm–1, η = 0.57 cP) and dichloromethane (σ = 28.2 dyne·cm–1, η = 0.44 cP) are not significantly different;7 thus, it is unlikely that Marangoni effects related solely to “static” differences between η and σ of the solvents are the dominant mechanism of honeycomb formation in the P3HT films.8 However, we propose that several other factors may promote Marangoni effects: (1) the addition of water due to evaporative cooling, (2) the changing CF and DCM compositions during the lateral drying process, and (3) the different solubility of P3HT in CF, DCM, and water, which are good, marginal, and poor solvents for P3HT. The first point may help account for the time-dependent growth of the pore size, as shown in Figure 6 (main text). Both CF and DCM have a low solubility in water (XCF 0.0012 and XDCM 5×10–4). In fact, chloroform and water are a well-known heteroazetrope. Thus, as water droplets condense on the surface it is reasonable to assume that liquidliquid demixing occurs between water and the CF:DCM blend. In this case, the time dependent pore 8 growth is a result of parallel water droplet nucleation and growth and the changing liquid composition due to rapid evaporation of DCM. The insolubility of P3HT in water causes the colloidal P3HT particles and amorphous P3HT to move into the CF:DCM phase, thereby establishing a P3HT-rich CF:DCM phase and a P3HT-lean aqueous phase. The partitioning of P3HT coupled with the changing composition of the CF:DCM blend and the growth of the aqueous domains may give to rheological and surface tension variations that promote (solutal) Marangoni effects between P3HT-rich and P3HT-lean phases. Convective Assembly Convective assembly was first observed by Perrin in 1909 during his seminal work on Avogadro’s number,9,10 but the details of this process weren’t clarified until 1992 when Denkov and co-workers investigated the 2D crystallization of latex spheres.10-12 This process involves the assembly or crystallization of colloid particles in evaporating films on solid surfaces by a two-step mechanism.13 A cartoon of the process, as reported by Kralchevsky et al. (Figure 4 in ref. 12), is shown in Figure S10.12 In the first step a hydrodynamic force, Fd, caused by a hydrodynamic flux, Jw, drags the particles in the thicker solvent layers inward towards the thinner regions. The flux, Jw, compensates for the solvent evaporating in the thinner region. The second step is crystal growth through convective particle flux, wherein the colloid particles assemble via capillary immersion forces, F, in the thinner solvent region. In the second step, the particle flux, and subsequent crystallization, is caused by the evaporation of the solvent from the already ordered array.12 FIGURE S10 Cartoon showing the process of convective assembly. (a) A hydrodynamic force, Fd, caused by a hydrodynamic flux, Jw, drags the colloidal P3HT particles in the thicker solvent layers inward towards the thinner regions. The flux, Jw, compensates for the solvent evaporating in the thinner region. Crystal growth occurs through convective particle flux, wherein the colloid particles assemble via capillary immersion forces, F, in the thinner solvent region. The particle flux, and subsequent crystallization and patterning (b), is caused by the evaporation of the solvent from the already ordered array. Adapted from ref. 12. 9 Solubility Parameter Differences, : Polymer/Solvent/Non-solvent Systems The characteristics of asymmetric polymer membranes produced by phase inversion processes in polymer/solvent/nonsolvent (p/s/ns) systems have been rationalized using criteria based on ternary phase diagrams, Flory-Huggins parameters, solvent/non-solvent diffusion models, and Hansen solubility parameter differences, to name a few.14-18 Although asymmetric membranes are processed using techniques that are quite different from our simple drop casting methods,16 it is interesting to draw from the extensive literature to address the morphological variations of our films. Of particular interest to us are the kinetics and thermodynamics of liquid-liquid demixing and the precipitation and crystallization of P3HT in the polymer-rich (good solvent) and polymer-lean (poor solvent) phases. Here, we use a factor, , to correlate the morphology of our P3HT films to the nature of the polymer-solvent and solventsolvent interactions. The factor for a p/n/ns systems is obtained from the equation,17 Δδ p – s Δδ p –ns δp Δδ s –ns [2] where the magnitude of the solubility parameter differences, Δδi–j, is a measure of the affinity between the ith and jth component. We calculated the solubility parameters of the chloroform solvent (δ s), the three non-solvent (δns), and the P3HT polymer (δp) using the Hansen parameter values available in the literature. A detailed description of this process is given in the Supporting Information. Our results are shown in Table 2 TABLE 2. Solubility parameters differences and values Δδp-s Δδs-ns Δδp-ns [MPa1/2] [MPa1/2] [MPa1/2] CF:DCM 4.83 3.29 6.06 0.488 CF:HEX 4.83 7.08 4.50 0.169 CF:AcN 4.83 15.13 15.90 0.279 Solvent Ruann et al. developed , which they related to the miscibility gap and the size of two-phase region of p/s/ns phase diagrams, as an accessible way to validate and predict the structure of asymmetric membranes using solubility parameter differences.17 Several reports show that as the value of decreases the asymmetric membrane favor macrovoid, sponge-like, and bead-like structures, i.e., macrovoid > sponge > bead.17-19 Since we do not yet have phase diagrams for the p/s/ns systems used in this study, we thought it would be worthwhile to test the correlation between and the morphologies of our films. Since this is based on solubility parameters, which correlate with fundamental polymer solution thermodynamics, e.g., Flory-Huggins theory,20-27 we confine our analysis to films dried under slow evaporation conditions. It is notable that the CF:DCM blend gives the largest value, thereby suggesting a correspondence between macrovoid structures in asymmetric polymer membranes and the honeycomb pattern of the CF:DCM film. The spherical structures in CF:AcN and CF:HEX may parallel the bead structures, but without an intermediate spongelike morphology we cannot verify this correlation. Frommer and Messalem studied the formation of large macrovoids in membranes produced by phase inversion processes in polymer/solvent/nonsolvent (p/s/ns) systems.28 They attributed these macrovoids to the initiation and 10 formation of convective flows near interfaces brought about by surface tension gradients. Solubility differences of P3HT in chloroform and dichloromethane may produce localized rheological and surface tension variations (Marangoni effects) due to mass transfer between P3HT-rich and P3HT-lean regions during the drying process. This picture is consistent with the mechanism posited by Frommer and Messalem. REFERENCES 1 Clark, J.,Chang, J.-F.,Spano, F. C.,Friend, R. H.,Silva, C., Appl. Phys. Lett. 2009, 94, 163306. 2 Scharsich, C.,Lohwasser, R. H.,Sommer, M.,Asawapirom, U.,Scherf, U.,Thelakkat, M.,Neher, D.,Köhler, A., J Polym. Sci. Pol. Phys. 2012, 50, 442-453. 3 Kim, B.-G.,Kim, M.-S.,Kim, J., ACS Nano 2010, 4, 2160-2166. 4 Park, B.,Ko, D.-H., J. Phys. Chem. C 2014, 118, 1746-1752. 5 Aiyar, A. R.,Hong, J.-I.,Nambiar, R.,Collard, D. M.,Reichmanis, E., Adv. Funct. Mater. 2011, 21, 2652-2659. 6 Johnson, C. E.,Boucher, D. S., J Polym. Sci. Pol. Phys. 2014, 52, 526-538. 7 Lide, D. R., Ed. CRC Handbook of Chemistry and Physics; CRC Press: Boca Raton, Fl, 2005. 8 Walker, B.,Tamayo, A.,Duong, D. T.,Dang, X.-D.,Kim, C.,Granstrom, J.,Nguyen, T.-Q., Adv. Energy Mater. 2011, 1, 221-229. 9 Perrin, J., Ann. Chim. Phys. 1909, 18, 1-144. 10 Denkov, N.,Velev, O.,Kralchevski, P.,Ivanov, I.,Yoshimura, H.,Nagayama, K., Langmuir 1992, 8, 31833190. 11 Denkov, N. D.,Velev, O. D.,Kralchevsky, P. A.,Ivanov, I. B.,Yoshimura, H.,Nagayama, K., Nature 1993, 361, 26-26. 12 Kralchevsky, P. A.,Denkov, N. D., Current Opinion in Colloid & Interface Science 2001, 6, 383-401. 13 Kralchevsky, P. A.,Nagayama, K., Advances in Colloid and Interface Science 2000, 85, 145-192. 14 Altena, F. W.,Smolders, C. A., Macromolecules 1982, 15, 1491-1497. 15 Yilmaz, L.,McHugh, A. J., Journal of Applied Polymer Science 1986, 31, 997-1018. 16 van de Witte, P.,Dijkstra, P. J.,van den Berg, J. W. A.,Feijen, J., Journal of Membrane Science 1996, 117, 1-31. 17 Ruaan, R.-C.,Chang, T.,Wang, D.-M., J Polym. Sci. Pol. Phys. 1999, 37, 1495-1502. 18 Guillen, G. R.,Pan, Y.,Li, M.,Hoek, E. M. V., Industrial & Engineering Chemistry Research 2011, 50, 37983817. 19 Ghasemi, S. M.,Mohammadi, N., Polymer 2013, 54, 4675-4685. 20 Eichinger, B. E.,Flory, P. J., Transactions of the Faraday Society 1968, 64, 2035-2052. 21 Eichinger, B. E.,Flory, P. J., Transactions of the Faraday Society 1968, 64, 2053-2060. 22 Eichinger, B. E.,Flory, P. J., Transactions of the Faraday Society 1968, 64, 2061-2065. 23 Biroa, J.,Zeman, L.,Patterson, D., Macromolecules 1971, 4, 30-35. 24 Patterson, D., Macromolecules 1969, 2, 672-677. 25 Delmas, G.,Patterson, D.,Somcynsky, T., Journal of Polymer Science 1962, 57, 79-98. 26 Blanks, R. F.,Prausnitz, J. M., Industrial & Engineering Chemistry Fundamentals 1964, 3, 1-8. 27 Patterson, D., Journal of Polymer Science Part C: Polymer Symposia 1967, 16, 3379-3389. 28 Frommer, M. A.,Messalem, R. M., Product R&D 1973, 12, 328-333. 11