Engineering Specification for FIRE DETECTION

advertisement

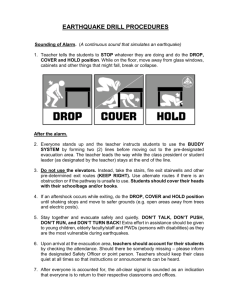

W50 Date: 02/02/2011 Issue 02 ENGINEERING SPECIFICATION FOR FIRE DETECTION & ALARM SYSTEM 1. Fire Alarm - General Requirements. The contractor shall supply, install, test, connect and commission a high quality fast-acting electronic Intelligent Addressable Fire Detection and Alarm System. The fire detection and alarm system shall comply with the requirements of BS 5839 Part 1 A1:2002, A2:2008 code of practice for system design, installation, commissioning and maintenance in and around buildings. The fire detection and alarm system shall be manufactured by an ISO 9001:2008 certified company and meet the term and definition in BS EN ISO 13943 and the following shall apply: The CIE (Control and Indicating Equipment) and peripheral devices shall be 100% manufactured by a single manufacturer (or division thereof). The CIE and peripheral devices shall be approved to the latest EN standard by an industry recognized and reputable third party test house such as LPCB/VDS. The complete system must also be approved to the latest EN54-13 and compliant with BS.5839 Part 1 A1:2002, A2:2008 Code of Practice. The fire detection system shall be comprised of the main fire alarm control panel, optical smoke/heat sensors, manual call points, electronic sounders, interface units, etc, each with its own inbuilt short circuit isolators. All components in the system shall be fully tested and approved by the manufacturer to be compatible with each other. All system cabling and other items deemed necessary for a safe, reliable and satisfactory system shall conform to the relevant and applicable requirements and recommendations of BS.5839 Part1 A1:2002, A2:2008, BS.5445: Part1 and BSEN54-2/A1:2006 and EN54-4/A2:2006. Date: 02/02/2011 Issue 02 Prior to placing an order for any equipment, the contractor shall submit comprehensive documentation comprising of working drawings, catalogues, technical datasheets, descriptive literature of components, maintenance manuals, etc, for the consulting engineer's study and approval. The contractor shall be responsible for making provision to train and instruct the client's personnel in the correct use, operation and supervision of the system, preferably prior to the handing over of the project. The contractor shall ensure prior to installation that the location of sounders indicated on the intended design will achieve a minimum of 65dBA in all areas (75dBA in bedrooms) and to include any changes / variations issued during the course of the contract and that all system components are manufactured by one manufacturer. 2. System Description. The fire detection and alarm system shall be designed to facilitate accurate identification of the source of heat / smoke / fire in its early stages to minimize the occurrences of false alarms. The fire alarm control panel shall continually collect and analyze the required device data to enable it to make the final decision on whether a fire or fault exists by comparing the plotted patterns from a fire sensor against known fire and fault patterns held in its memory. The operational principle of the system shall be on a true Intelligent basis, and shall provide the facility to print the output from a fire sensor over a period of time or to transfer the data electronically to a PC for storage and analysis. All system components and devices shall be connected to two core addressable loop circuits (as shown in the typical schematics) with each component having its own individual inbuilt isolator. Removal or disconnection of any component from the loop shall not affect the functioning and performance of other components and the system. Please note that the use of group or zonal isolators which are used to isolate a section of a loop in case of a cable fault is not acceptable. The system shall be of Intelligent addressable type, i.e. all the devices on the loops of the FACP shall be allocated addresses automatically from the panel at the time of system power up on a sequential ‘numerically lowest unused’ value basis (algorithm) and also given an address during commissioning, the value of which shall be stored in non-volatile memory, within the electronics module of the device. This value shall be interrogated during loop allocation and provided it is verified as being valid it shall be used to set the device primary address. Inntelligent system protocol Addressing shall include the benefit of Soft Addressing and also overcome the limitations of Hard Addressing procedures. If devices are added or removed at a later point, all the existing devices in the loop must keep the same address, zone and text location. The Control Panel shall allocate the addresses in strict sequential order when the loop is powered up in order to speed up commissioning and ensure that it is impossible for two devices to have the same address. The Fire Detection and Alarm System, MUST have the capability for both soft and hard addressing and should it be required, a hand held programming tool must be available to allow an optional manual method of device setup and interrogation. Date: 02/02/2011 Issue 02 Fire Detection and Alarm Systems which rely only on soft addressing or hard addressing techniques, are not acceptable. The fire alarm control panels shall be of a modular design complying with BS3116: Part 4 and facilities shall be provided to constantly monitor and check the following circuits and fault conditions, and to give the following features: the power supply to the loop(s). battery impedance to be checked every 4 hours. open-circuit, short-circuit, earth fault and any other fault condition in the loop wiring. communication failures and errors in all cards and loops. monitoring of all devices status to create a table of each analogue channel for event analysis. all devices i.e., Optical/Heat Sensor, Fire Alarm Interface Units, Manual Call Points, Sounders etc. shall be installed on the same loop and all interface operating relay / switch devices, auxilliary relays (controlling remote plant items, door release units etc) be monitored for faults. the FACP shall support loop powered and networked repeaters. Network repeaters shall have a large interactive, touch sensitive, backlit, 320x240 viewable LCD screen. Repeaters shall be programmable as passive (indication only) or active (indication and control) and must be equipped with EN54-4 approved power supplies. the addressable device Labelling procedure may be carried out either by using the inbuilt touch screen display oft the FACP, by the use of a PC based dedicated software package or by using a handheld programming tool for basic on-site programming. all events, i.e. Fire, fault or warning, shall be recorded with time, date and place of occurrence in the memory event log of the FACP. These events may either be displayed on the control panel LCD display, transferred electronically to PC or printed, as required. provision shall be available for the fire alarm control panel to silence the loop powered alarm sounders but maintain visual indication until the system is reset. the facility to introduce / change delay periods in operating loop powered individual sounders or groups of sounders, shall be available to be programmed without the need to change any hardware. the facility shall be available to network up to 126 FACP’s using an international open protocol bus system which must be compatible with Lon, Bacnet or Modbus. Date: 02/02/2011 Issue 02 3. System of Operation / Cause and Effect. Cause and effect procedures must be defined by the contractor either as a basic “one out all out” or as a detailed evacuation procedure. Examples may include the following: o Stage 1: If a fire condition is detected in any area, only the local sounder (or group of sounders) to operate. o Stage 2: If the alarm is not acknowledged within a predetermined time delay then all sounders in the entire system to operate. The Control Panel should have the facility for Alarm Acceptance timer T1/T2 programming in order to allow acceptance and verification delays times to be set according to the evacuation procedure requirements. 4. System Components and Devices. MAIN FIRE ALARM CONTROL PANEL. The control panel shall be processor controlled using Intelligent analysis techniques to detect smoke / heat / fire conditions. The control panel shall be complete with, but not limited to, the following elements and shall be approved to the latest BSEN54-2 A1:2006 and BSEN54-4 A2;2006 by an industry recognized and reputable European third party Test house (LPCB, VDS). A large interactive, touch sensitive, backlit, 320x240 viewable LCD screen capable of accessing the comprehensive range of programming and operating functions of the FACP through its touch screen Qwerty keyboard. The Panel must have a total of 96 inbuilt Fire Zone LED indicators as required by BS5839. An inbuilt 40 character thermal printer operating through a window. There shall also be an option to enable the printer when the door is closed. A touch screen qwerty keyboard to enable labeling of devices descriptions and any correction in label if required, in addition to but without necessitating the use of a PC. The system shall include an Integral sealed lead acid battery and charger, with the ability to provide a minimum of 24 hour back up in normal operation and half an hour full alarm load in the event of supply mains failure. Fire, Fault, Warning and Power LED indicators. Date: 02/02/2011 Issue 02 Simple menu driven functions with passcode protection shall allow users to access an extensive range of software based features such as: o An event log showing at least the last 9,999 events. o A facility to Replace and Add devices via the Touch Screen. o Logs of current faults and fires. o Graphical analysis of Intelligent sensor information. o The facility to enable or disable sensors, zones, sounders, interface units. o Addressable device status. o Printer status to allow ‘On Request’ or ‘Auto with filtering’ options. o Check Config facility to identify device type mismatch and to pinpoint loop open and short circuit faults. o The Fire Alarm Control panel shall be capable of controlling the volume and tone of all addressble Loop powered sounders. o The Fire Alarm Control Panel must have the flexibilty to pulse the addressable device led status indicators during normal operation, or to withhold normal operation indication.This feature must be programmable by the touch screen at access level 3. The Fire alarm control panel must be capable of supporting up to 60 addressable loop powered sounders per loop. The fire alarm control panel shall support Voice Alarm interfaces to replace loop powered sounders in certain applications. The control and indication touch screen display shall be enclosed behind an optional protective cover if required. Each loop shall support a maximum of 200 Intelligent Addressable devices per loop, with a maximum loop length of 2km of 2core 1.5mm 2 screened fire resistant cable. A LON based computer communication option shall be available. The control panel shall provide a minimum of 2 Master alarm sounder circuits (4 sounder circuits) operating at 24V dc with a maximum capacity of 750mA per circuit. The system shall provide a secure networking facility to indicate a remote zone number and remote zone text across the network. In addition to the above, all other necessary controls, elements and accessories shall be included to provide a complete and efficient panel conforming to the requirements of BS.5839: Part1, BS.5445: Part 1 and BSEN54-2 A1:2006 and BSEN54-4 A2:2006. BATTERY AND CHARGER EQUIPMENT FOR FIRE ALARM SYSTEMS. Date: 02/02/2011 Issue 02 Batteries for fire and/or security alarm systems shall be of sealed Lead Acid type complying with BS.6115. Each battery shall have a storage capacity sufficient to maintain the system for 24 hours in the standby mode and to supply the full alarm load for one hour without the battery terminal voltage falling below 90% of its nominal value. The battery impedance must be monitored by the control Panel as per the requirement of the latest EN54-4 and the charger must be temperature compensated to extend the life of the batteries. SMOKE / HEAT DETECTORS. These shall be of Intelligent addressable optical / heat type with inbuilt isolator in a single unit. The optical sensing element shall monitor for visible smoke from slow smouldering fires. The smoke and heat sensing design shall be compliant to BSEN54-7 and BSEN54-17 and must be CPD approved by an industry recognised and reputable third party European test house (LPCB, VDS). Similarly Heat detectors must be approved to BSEN54-5 and BSEN54-17 and Beam type smoke detection shall also be approved to BSEN54-13. All smoke and heat sensors shall be comprised of three components: Termination Plate, Electronics Module and a replaceable Sensor Chamber. The termination plate shall incorporate the terminals for wiring only and shall not contain any electronic parts. The electronics module shall plug onto the termination plate as a second fix item. It shall have microprocessors, short-circuit isolators and all electronic components & circuitry suitable for an Intelligent addressable system. This design shall allow the smoke detector Sensor Chamber alone to be replaced, should it become contaminated due to a build up of dust from the surrounding atmosphere. All detectors (smoke + heat) shall have 360o viewing LED indicator. Smoke detectors should have drift compensation and chamber monitoring as standard. MANUAL CALL POINTS. These shall comply with the requirements of BS.5839 Part 1, BSEN54-11 and CPD approved to BSEN54-11 and BSEN54-17 by an industry recognised and reputable third party European test house (LPCB, VDS). These shall be complete with all electronic components and circuitry for a safe addressable device. Optional Polycarbonate covers shall also be available if required. The manual call point shall have an inbuilt short circuit isolator and an inbuilt microprocessor to ensure a response time of less than 3 seconds. The unit shall incorporate a key operation facility for testing purposes and a specially designed film fitted over the glass to prevent fragmentation when broken or designed for use with a resettable element. Date: 02/02/2011 Issue 02 INTERFACE UNITS. These shall be used to provide interfacing facilities triggering into the fire alarm system from 3rd party equipment and going out from the fire alarm system to other 3rd party equipment. They shall be suitable to allow ‘volt-free’ connections from (or to) other services required to be interfaced with fire alarm system, e.g., interfacing with AHU's, BMS, FM200 System, Elevators and Pressurisation Fans etc. They shall be of a safe addressable type with inbuilt isolators. All inputs and outputs are to provide the facility to be fully monitored for cable faults. All Intelligent addressable Loop Interfaces shall have inbuilt short circuit isolators and must be loop powered with no additional External Power supply Door retention or operation devices supplied and fitted by the contractor shall be in accordance with BS.5839: Part 3. WIRING All cables associated with the Fire Alarm installation shall be of fire resistant 2 core 1.5mm2 screened type. Cables shall comply with BS 7629: 1993 and BS 6387. The use of a 4 core cable for the addressable loop circuit must be specifically avoided. The cable for use on the Fire Alarm addressable loop circuit shall be of the following type and specification, and shall typically not exceed 2 km per circuit: The cable is to comply with BS 6387 having typically no more than 2 cores. A maximum of 0.5 micro-farad intercore capacitance. A maximum of 13 ohms per core. Each core having no less than 1.5mm 2 cross sectional area with an inherent or thorough metal conduit screen for earth continuity in order to produce electrical protection & screening and having protection from heat and mechanical damage. The cable screen must be suitable for through termination at each system device whilst maintaining separation from building earth. Multi core cables having more than 2 cores shall not be allowed for loop wiring due to inadequate separation and likely interference problems. FIRE ALARM COMMISSIONING. The service of a competent, factory-trained engineer or technician authorized by the manufacturer of the fire alarm equipment shall be provided to technically supervise and participate during all of the adjustments and tests for the system. The installed fire alarm system shall be operated to test all trigger devices, sounders, visual alarms, control panels, door retainers, fire shutters, fan controllers, fire brigade signaling, power supplies etc, as may constitute the whole of the fire alarm system. Final acceptance tests shall be executed as specified in the particular specification section and/or drawing and the performance of the system Date: 02/02/2011 Issue 02 recorded on the Final Acceptance Record Sheets and Certificate provided by the Contractor based on Appendix B of BS.583 Part 1 A1:2002, A2:2008. SYSTEM COMMISSIONING. Date: 02/02/2011 Issue 02 POST CONTRACT MAINTENANCE. Complete maintenance and repair service for the fire alarm system shall be available from a factory trained authorized representative of the manufacturer of the major equipment for a period of five (5) years after expiration of the guaranty. As part of the bid/proposal, a quotation shall be provided for a maintenance contract to provide all maintenance, testing and repairs as detailed below. A quotation shall also be provided for unscheduled maintenance/repairs, including hourly rates for technicians trained on this equipment, and response travel costs for each year of the maintenance period. Submittals that do not identify all post contract maintenance costs will not be accepted. Rates and costs shall be valid for the period of five (5) years after expiration of the guaranty. Maintenance and testing shall be on a semi-annual basis or as required by the Authority Having Jurisdiction (AHJ). The contractor describing the protocol for preventive maintenance shall provide a preventive maintenance schedule. APPROVED MANUFACTURER Cooper Fire Systems / Menvier / JSB Contact details: Kelvin Spencer Export Sales Manager Cooper Fire Wheatley Hall Road, Doncaster, South Yorkshire, DN2 4NB M: +44 (0)7968 568303 F: +44 (0)1302 303 345 E: kelvin.spencer@cooperindustries.com W: www.cooperfire.com