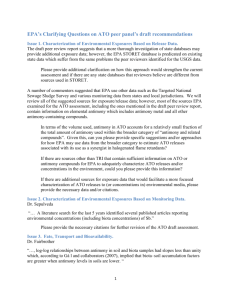

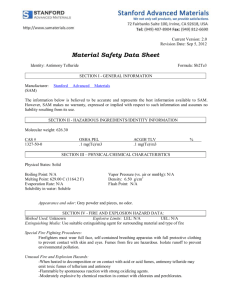

Antimony in the Costerfield Area

advertisement