Liquid Nitrogen - University Wiki

advertisement

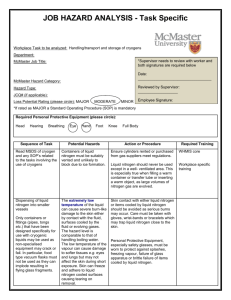

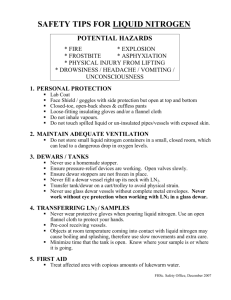

Department of Chemistry and Department of Biology and Biochemistry: Generic Risk Assessment: The Use of Liquid Nitrogen. The assessor should assign values for (a) the level of harm (hazard severity) that could result from using the hazard, and (b) the likelihood of it occurring (taking into account the frequency and duration of exposure) on a scale of 1 to 5, then multiply them together to give the rating band: Degree of Harm (A) Likelihood of Occurrence 1 – Trivial (eg discomfort, irritation, slight bruising, self-help recovery) 2 – Minor (eg small cut, burn or abrasion, basic first aid need) 3 – Moderate (eg strain, sprain, infection, poisoning, incapacitation > 3 days, fire) 4 – Serious (eg fracture, hospitalisation >24 hrs, incapacitation >4 weeks, severe damage to building) 5 – Fatal (single or multiple) (B) 1 – Remote (almost never, not expected at all) 2 – Unlikely (foreseeable, but only occurring rarely) 3 – Possible (could occur, but uncommon) 4 – Likely (recurrent but not frequent) 5 – Very likely (could occur frequently) The risk rating (high, medium or low) indicates the level of response required to be taken when designing the action plan. Risk Assessment Matrix (B) (A) Risk Rating Bands (A x B) Trivial Minor Moderate Serious Fatal Remote 1 2 3 4 5 Unlikely 2 4 6 8 10 Possible 3 6 9 12 15 Likely 4 8 12 16 20 Very likely 5 10 15 20 25 LOW RISK (1 – 8) MEDIUM RISK (9 - 12) HIGH RISK (15 - 25) Continue, but implement additional reasonably practicable controls where possible and monitor regularly STOP THE ACTIVITY Continue, but review periodically to ensure controls remain effective Identify new controls. Activity must not proceed until risks are reduced to a low or medium level Risk Assessment of: Liquid Nitrogen use at Bath University. Assessor(s): Work Authorised by: Date: Updated May 2015 Overview of activity / location / equipment / conditions being assessed: The handling and use of liquid nitrogen in any experimental/ research work in the Department of Chemistry or Department of Biology and Biochemistry at the University of Bath. Hazards Liquid nitrogen evolves nitrogen gas which is inert and non-toxic but there is a risk of asphyxiation in situations where high concentrations may accumulate and displace air from the room. The risk of oxygen displacement is increased when nitrogen is stored or used in poorly ventilated areas, or small spaces. Cold nitrogen gas (from the evaporating liquid) will fill the room from the floor upwards (denser than air). Short exposures to very cold gas/ vapour leads to discomfort in breathing whilst prolonged inhalation could trigger an asthma attack, and in extreme cases may damage (burn) lung tissue. Liquid nitrogen can cause cryogenic burns if the substance itself, or surfaces which are or have been in contact with the substance (e.g. metal transfer hoses), come into contact with the skin. Local pain may be felt as the skin cools, though intense pain can occur when cold burns thaw and, if the area affected is large enough, the person may go into shock. Skin may stick to cold surfaces, including clothing saturated with cryogenic liquid, and must not be pulled away until the affected area has been “thawed” (exposure to tepid water), as tissue can be torn. Using equipment or tubing made of rubber, synthetic rubber, carbon steel, plastic or glass with liquid nitrogen can lead to failure of the material due to brittle fracture at low temperature. These materials may implode/ explode from incorrect use/ failure with shrapnel causing cuts/ puncture wounds/ eye injuries. - Embrittlement of plastic Eppendorf (or similar) tubes can cause the lids to pop off at high speed. - The glass inner of household vacuum flasks (e.g., Thermos) can shatter/ implode if used to hold liquid nitrogen. - Lino can become cracked and raised if in contact with cryogens for extended or repeated exposures (this may increase risk of trips). If a warm hollow tube is inserted into liquid nitrogen, liquid will spout from the tube due to rapid expansion of the liquid inside the tube and gasification. Ice plugs are formed when moisture in the air condenses at the neck of open dewars, building up to create an icy blockage. If the blockage is complete, this is potentially explosive as the evaporating nitrogen continues to build pressure in the dewar. Oxygen in air surrounding pipes and vessels with liquid nitrogen (-196 ˚C) can condense, forming pools of liquid oxygen (-183 ˚C) or liquid air. Liquid oxygen can also form in cold traps cooled by liquid nitrogen, and appears as a blue liquid. Liquid oxygen can support vigorous combustion of materials not usually considered flammable, and enriched atmospheres may be explosive. Dewars may be heavy - a standard 25 L lab dewar will weigh approximately 15 kg empty, and 35-40 kg when full. The larger pressurised dewars are usually mounted on wheels for easier transport, but these should only be transported on flat surfaces. Control of one of these dewars can easily be lost when attempting to manoeuvre up or down a slope, and this process will usually require two people. In addition, moving the pressurised dewars on slopes or rough ground (including bumps) is not recommended by the manufacturers, as the delicate internal structure at the neck may be damaged and the internal vacuum lost. If this happens, it is usually uneconomical to repair and the dewar will require replacement. General Controls • • • • • Never store cryogenic substances (or allow them to vaporise) in enclosed areas, including: fridges, freezers, cold rooms, sealed rooms or basements. Storage of cryogenic liquids must be located away from workplace transport traffic, and site drains. Dewars should be stored in secure enclosure to prevent access to unauthorised persons. Storage area to be designed fit-for-purpose and maintained in good order, i.e., kept clear of any combustible materials, with a concrete rather than tarmac floor. Ensure dewars are completely empty, dry and at ambient temperature before putting into general storage. Transport of any cryogenic gas in an enclosed vehicle is dangerous, and an open vehicle, trailer, or separate cab from load compartment must be used. Lab Induction: No staff are allowed to start work until they have been given an induction. The induction includes instruction that all work must be Risk Assessed. Staff are sent out an induction summary to remind them of the induction details and to send any new staff to the Technical Team. Hazard Oxygen/ air displacement resulting in Asphyxiation Who could be harmed? Individual and others in area Control measures needed to minimise risk Risk rating after controls implemented A B AxB 5 2 10 A task-specific risk assessment must be filled in, understood and signed before working with liquid nitrogen. Large vacuum insulated tanks (dewars) are normally stored outside buildings due to the quantities of liquid. If outdoor storage is not possible, the storage area must be sufficiently ventilated to ensure oxygen levels are maintained above 19.5 %, taking into account the normal evaporation of all dewars within the room and above 18 % taking into account the complete spillage of the largest dewar. Always use liquid nitrogen in a well-ventilated area. • • • • • • Never store in an unventilated cupboard or small room. Ensure hazard warning signs are displayed (yellow triangle with exclamation symbol and text: ‘Liquid nitrogen’) on dewars and at access points to storage area. Use only equipment designed for purpose of storing liquid nitrogen. Never seal an unpressurised/ open dewar (e.g., only use loose-fitting cap). Vessels must always be attended when filling. Minimise number of people in the area when filling, and consider personal oxygen monitors. Do not overfill vessels. • • • • Use only proper transfer equipment. Transfer tubes and dewars must be stainless steel, copper/ copper alloy or aluminium. Do not use hollow dipsticks - use solid metal or wood. If fitted (assess according to oxygen displacement calculations for room and dewar sizes), oxygen monitors should be located approximately 1 metre up from the floor, set to alarm if oxygen levels reach 19.5 % or lower. The following points must be considered: • Ventilation - is it adequate? Some rooms do not have any air supply or extract system and so there is little or no air change. Can the door be left open to allow gas to dissipate when vessels are being filled? Can vessels be filled elsewhere? • Do people spend significant periods working in the room (on unrelated tasks)? • Is the room fitted with an oxygen deficiency monitor/ alarm? • Is the door fitted with a viewing panel? Note: Liquid Nitrogen Containers will be marked with information about where they are to be stored and filled. Asphyxiation in lifts Lift users • • • Cold Burns Liquid nitrogen at -196 ˚C, materials liquid has contacted. May be as a result of spillage. Individual and others in area • • • • • • • • • • • • • Liquid nitrogen containers must not be accompanied in lifts. If a lift is used then it will be closed to all passengers with signage posted and preferably use of barrier tape. The vessel will be manoeuvred into the lift, and the lift called to the destination floor. 5 2 10 Wear dry, thermally insulated gloves, to EN511, designed to handle cold temperatures. Hands (either bare or gloved) must never be immersed in liquid nitrogen. Gloves with elasticated cuffs are recommended to prevent ingress of liquid. Wear eye protection or full face visor (to EN166) when dispensing or handling liquid nitrogen. To minimise splashing, fill slowly while the vessel cools (increased boil-off to start). Only use containers suitable for the material being used, i.e., purpose-designed dewar. Use a transfer tube or funnel to decant liquid into narrow-necked open dewars. Use a funnel to pour liquid into narrow-necked openings in cryostats and cold traps. If handling liquids in open dewars, wear closed, non-porous shoes (no sandals, or open-toes). Wear lab coat, overalls or cryo-apron while dispensing/ filling dewars. Sleeves and trousers must be worn outside gloves and footwear. Use tongs to place or retrieve items from cryogenic liquid. When removing cell-line cages from storage, use a hook to find the handle and raise the cage. 2 3 6 Slips and Trips Impact Individual and others in area • • Individual and others in area Manual Handling Individual Musculoskeletal injuries may be sustained from handling heavy or awkwardly shaped vessels. Inexperienced users Individual user Store dewars away from doors, access routes and fire escapes. Clear up any frost/ ice or melt-puddles resulting from use of cryogens as soon as possible. 3 2 6 • Wear lab coat and eye protection (to EN 166.F) at all times. • Use purpose-designed dewars with liquid nitrogen - household vacuum flasks (Thermos, etc) must not be used. 3 2 6 • Follow the University’s Manual Handling Guidelines. • Use the associated trolley and tipping mechanism to dispense nitrogen to bench-top (1-2 litre) dewars. • Movement of larger containers may require two people, e.g., if there is a requirement to move between differing levels. • Individuals must be aware of their own limitations and ask for help if needed. 3 3 9 5 2 10 Never dispose of cryogenic materials down the sink - waste pipes can potentially be cracked resulting in leaks. Liquid nitrogen dewars must be visually inspected before use and replaced if damaged. Storage vessels should be CE standard. Containers must be used as per manufacturer’s instructions. Thermos flasks and other household containers must not be used as they are not designed for liquid nitrogen storage, and they could shatter. 3 2 6 Free-venting dewars must be fitted with their proper loose-fitting cap (in good working order), which controls vent gas and minimises ingress of moisture. Dewars will be stored in a well-ventilated place under cover (protected from adverse weather if outside) Dewars must not be left wide open to the atmosphere. 3 2 6 Users must be trained how to dispense from these vessels. Use a phase separator if dispensing into open dewars to reduce splashing. If unavailable, start the fill slowly until boil-off is reduced. 4 2 8 Provide information, training and supervision: Before using liquid nitrogen, all staff must complete a risk assessment relating to their specific work and be trained by a competent person. Implosion or Individual and broken equipment others in area from incorrect use or failure. Ice plugs (partial or complete) Individual and others in area Pressurised dewars Individual and others in area Inexperienced workers must be supervised by a competent cryogens user. Oxygen Enrichment resulting in fire/ explosion Transport in vehicles Impact from moving load, asphyxiation, burns. Ensure the vessel is regularly serviced and maintained - tag must be current. Vessel must have burst disc and pressure release valve. During transport, avoid slopes and rough ground (including kerbs, gratings and drain covers). Individual and others in area Driver and any passengers Ensure pipes, etc. are well insulated and not above tarmac. Remove any combustible material from storage areas. Do not suck air into a cold trap for long periods, as liquid air/ oxygen will collect o Empty traps regularly (after each solvent/ material removed), to minimise adverse reactions Never transport a dewar in the passenger compartment of a car, or cab of a van/ truck. Dewars must be fully secured in an upright position during transport (consider collision) Ensure load compartment is well ventilated. Remove the dewar from the vehicle as soon as possible after arrival. 5 4 2 1 4 10 First Aid: Where inhalation has occurred, the victim (who may be unconscious) will be removed to a well ventilated area where possible. Rescuers must not put themselves at risk - an oxygen-depleted area must not be entered unless over 18% oxygen atmosphere. Breathing apparatus may be required (trained personnel only). The casualty should be kept warm and rested whilst medical attention is obtained. If breathing has stopped, commence CPR and summon medical attention immediately. Where contact has occurred, the temperature of the affected area will be allowed to slowly return to normal. For minor injuries, clothing should be loosened and the person made comfortable. Clothing must never be pulled away from burned or frozen skin. Flush the affected area tepid water (40 ˚C) for at least 15 minutes and apply a sterile dressing to protect the injury. Seek medical attention. Never apply any form of direct heat to a cold burn. For other injuries or shock, apply first aid as far as is practicable and summon medical attention as soon as possible. All incidents, injuries and near misses must be reported as soon as possible. Emergency Procedures Ensure all users know the correct procedures in case of emergency. In the event of a small spillage (under 1 litre): • Allow liquid to evaporate • After return to room temperature, inspect area. Report any infrastructure damage to Estates. If equipment has been damaged, arrange for repair. In the event of a large spillage (over 1 litre) or accidental release, follow these procedures: • Evacuate the area and restrict access. Deploy warning signs and cordon off area if necessary. • Ventilate the area to speed evaporation of any spilt liquid allow resultant gas to disperse. - Open doors and windows or activate forced ventilation, if safe to do so. • Try to stop the release if at all possible e.g. turn off valves, but only if it is safe to do so - wear PPE. • Do not re-enter area unless it is proved safe to do so. The presence of oxygen deficiency monitors will indicate the oxygen levels in the vicinity. • Prevent liquid nitrogen from entering drains, basements, pits or any confined space where accumulation may be dangerous. If you find an unconscious person in an area where liquid nitrogen is used, immediately raise the alarm and tell Security and the Emergency Services that asphyxiation is suspected. Open the door to increase ventilation to the area, and if possible, increase the forced ventilation to the room. Do not attempt to enter the area unless you know the oxygen level is above 18 %. Oxygen Enrichment. If present, liquid air/ oxygen will appear as a blue liquid. • If seen (e.g., under pipes), remove source of liquid nitrogen and allow to warm slowly to room temperature, open to the atmosphere (preferably well ventilated). • If seen in a cold trap, keep the pump on (dewar removed) until the blue colour disappears, switch off the pump and slowly open to the atmosphere, allowing trap to warm to room temperature. Assessment of Ventilation Requirements for worst case scenario liquid nitrogen spill. Nitrogen is the main component of air and is present at approximately 78% by volume (oxygen is approximately 21% and argon 1%). Any alterations in the concentrations of these gases, especially oxygen, have an effect on life. In the case of liquid nitrogen, there is a risk of asphyxiation where ventilation is inadequate and the nitrogen gas evolved can build up and displace oxygen from the local atmosphere. An atmosphere containing less than 18% oxygen is potentially hazardous and entry into atmospheres containing less than 20% should be avoided. In these instances, consideration should be given to the installation of oxygen monitoring equipment. The process of asphyxiation caused by depleted oxygen levels can happen rapidly and without warning to the victim. The reduction in atmospheric oxygen results in loss of mental alertness and distortion of judgement and performance. The individual will be unaware of this happening. When going in to help unconscious colleagues, would-be rescuers often become additional fatalities, overcome by the lack of oxygen very quickly. Oxygen monitors are usually set to alarm at 19.5 %, and rooms must be evacuated if the level reaches 18%. The general effects of reduced oxygen content in the atmosphere are given in the table below: Oxygen content (vol. %) 14-21 11-14 8-11 6-8 0-6 Effects and symptoms Increased pulse rate and tiredness. Physical and intellectual performance diminishes without the person being aware. Possibility of fainting without prior warning. Fainting within a few minutes – resuscitation possible if carried out immediately. Fainting almost immediate, death ensues, brain damage even if resuscitated. Calculation: Calculate the size of your room in cubic metres (m3) = height x width x length Need to calculate for worst case scenario, using largest dewar (use volume when full) and gas expansion for nitrogen (1 L of liquid expands to 683 L of gas), so: potential volume of nitrogen = dewar size in litres x 683 Convert litres to m3 by dividing by 1000. Calculate remaining air volume = room volume - potential nitrogen volume Volume of oxygen = 21(remaining air/ room volume) The volume of oxygen must be above 18 % for safe operation, if below this then ensure operations/storage is in larger volume rooms or use oxygen monitors. Example calculation: Room is 3 m wide, 4 m long and 2 m high = 24 m3 Dewar is 25 litres. Potential N2 gas = 25 x 683 = 17075 L Convert potential N2 to m3 = 17 m3 Calculate remaining air volume = 24 - 17 = 7 m3 Volume of oxygen = 21(7/ 24) = 6.1 % Remaining oxygen level in the room would be 6.1%, so relocate the vessel to a larger space or consider installation of oxygen monitors.