Fire Protection Compliance Program Checklist

advertisement

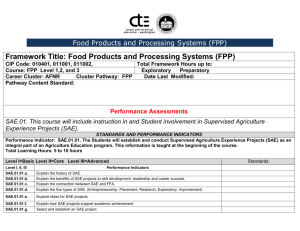

Implementation Strategy: One of the key parts of monitoring is to implement a program for inspecting and maintaining power tools at appropriate intervals. For Best Results, combine this Calendar with your regular preventive maintenance and inspection schedule for portable powered tools covered. MONTHLY FIRE PROTECTION COMPLIANCE PROGRAM STEP 1: SCHEDULED CHECKS—EACH MONTH MAKE SURE YOU: Action Step Date Done Comments/Results/Corrective Action Visually inspect portable fire extinguishers Inspect respiratory protective equipment of fire brigade STEP 2: UNSCHEDULED RESPONSE ACTIONS—HAVE ANY OF THE FOLLOWING THINGS HAPPENED IN THE PAST MONTH: TRIGGER YES NO RESPONSE CHECKLIST, IF YES New workers started work [ ] Educate them about fire extinguishers [ ] Educate them about dangers of fighting incipient fires [ ] Review the Fire Prevention Plan with them Comments: You developed or changed your Fire Prevention Plan (FPP) or Emergency Action Plan (EAP) [ ] Review the FPP and EAP with all workers covered by the plan and go over the changes Comments: You changed the duties of a worker under the FPP or EAP [ ] Review the FPP/EAP with the worker [ ] Train worker to use fire extinguishing equipment if he/she’s required to do so under the plan Comments: Hose systems were operational You changed fire extinguishing and/or fire protection equipment used [ ] Inspect the system to assure all of the equipment and hose are in place, available for use and in serviceable condition [ ] Notify all affected workers of change [ ] Educate affected workers in use of new equipment 1 Concerns about current Program expressed by workers, supervisors, safety committee, etc. Comments: [ ] Were concerns thoroughly investigated? [ ] Did investigation find anything to suggest workers are at increased risk? IF YES: Review the adequacy of current: [ ] Hazard assessment [ ] EAP [ ] FPP [ ] Fire suppression equipment and systems Comments: BI-MONTHLY FIRE PROTECTION COMPLIANCE PROGRAM SCHEDULED CHECK—EVERY 2 MONTHS MAKE SURE YOU: Action Step Date Done Comments/Results/Corrective Action Test the reliability and adequacy of non-supervised employee alarm systems SEMI-ANNUAL FIRE PROTECTION COMPLIANCE PROGRAM SCHEDULED CHECK—EVERY 6 MONTHS MAKE SURE YOU: Action Step Date Done Comments/Results/Corrective Action Check the weight and pressure of refillable containers of fixed extinguishing systems and provide maintenance if the container shows either: > 5% loss in net content or weight; or > 10% loss in pressure Weigh factory charged nonrefillable containers of fixed extinguishing systems that have no means of pressure indication and replace any that shows > 5% loss in net weight List the inspection and maintenance dates on a tag attached to the container or a central location until 2 the container is replaced or checked again, whichever comes first ANNUAL FIRE PROTECTION COMPLIANCE PROGRAM SCHEDULED CHECK—EVERY 12 MONTHS MAKE SURE YOU: Action Step Date Done Comments/Results/Corrective Action Do a maintenance check on all portable fire extinguishers (other than stored pressure extinguishers) Record the date of annual maintenance and keep the record for at least a year or life of the shell, whichever is less Test supervised employee alarm systems for reliability and adequacy Inspect the equipment of the fire brigade Inspect hose systems (assuming they haven’t been inspected in the previous 12 months) to assure all equipment and the hose are in place, available for use and in serviceable condition Unrack and inspect hemp or linen hose on existing hose systems for deterioration and then rerack using a different fold pattern Perform a main drain flow test on each sprinkler system in use Have a person knowledgeable in its design and function test the fixed fire extinguishing systems to verify that it’s in good operating condition Sample the dry chemical supply of all but stored pressure systems of fixed extinguishing systems that use dry chemicals to ensure it’s free of moisture that can cause caking or lumping Review the training of workers designated to inspect, maintain, operate or repair fixed extinguishing systems and ensure it’s up to date Provide refresher education on fire 3 extinguisher use and the hazards of fighting incipient fires to any worker who hasn’t received such education in past year Provide refresher education on the FPP and EAP to any worker who hasn’t received such education in past year Provide refresher training to any workers required to use fire extinguishing equipment under the FPP or EAP who haven’t received such training in the past 12 months OTHER ACTIONS Every 2 Years: Open the inspector’s test valve of automatic sprinkler systems to ensure the system’s operating properly. Every 5 Years: Test carbon dioxide extinguishers and nitrogen or carbon dioxide cylinders used with wheeled extinguishers at 5/3 of the service pressure as stamped into the cylinder. Every 6 Years: Empty stored pressure dry chemical extinguishers that require a 12-year hydrostatic testing and subject them to applicable maintenance procedures—except for dry chemical extinguishers having non-refillable disposable containers which are exempt from this requirement. http://compliance.safetysmart.com/wp-content/uploads/2011/09/Fire-1.pdf Tools & Implementation * Use the “Model Fire Inspection Questionnaire” to ensure the effectiveness of fire inspections; * Use the “Fire Safety Audit Form” to carry out periodic audits of your fire safety measures; * Use the “Workers’ Fire Safety Questionnaire” and “Supervisors’ Fire Safety Questionnaire” to determine if safety measures are working; * Use the “Model Fire Incident Investigation Form” to investigate tool injuries and incidents; * Use the “Corrective Actions Form” to determine how to modify and improve fire safety measures. 4