tests hence

advertisement

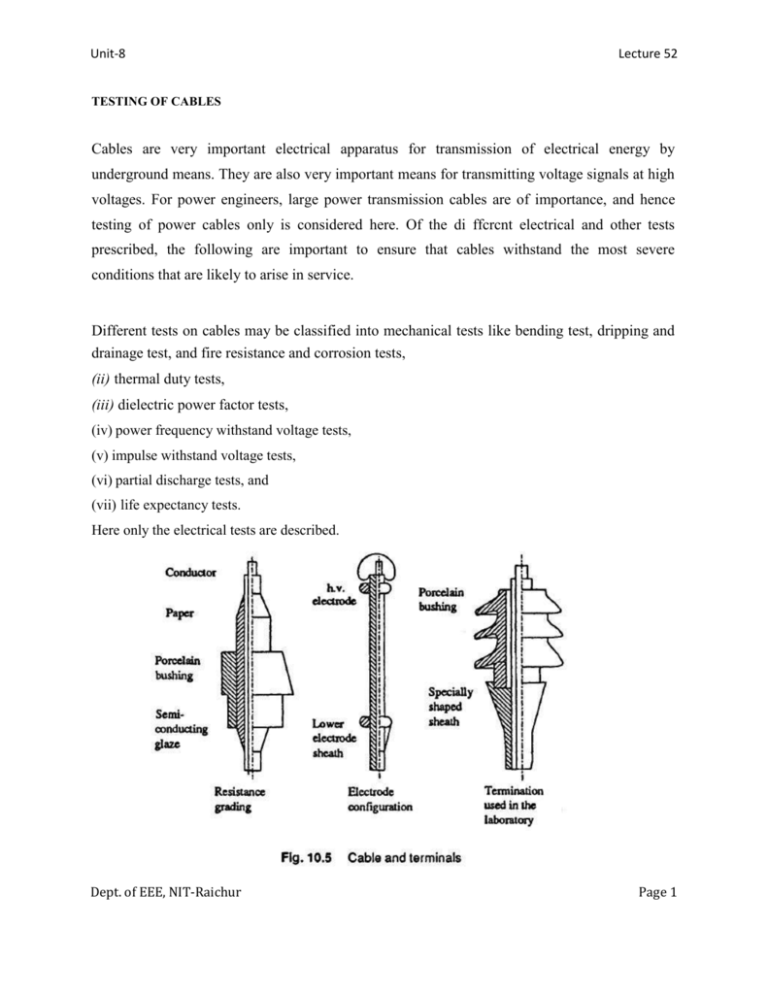

Unit-8 Lecture 52 TESTING OF CABLES Cables are very important electrical apparatus for transmission of electrical energy by underground means. They are also very important means for transmitting voltage signals at high voltages. For power engineers, large power transmission cables are of importance, and hence testing of power cables only is considered here. Of the di ffcrcnt electrical and other tests prescribed, the following are important to ensure that cables withstand the most severe conditions that are likely to arise in service. Different tests on cables may be classified into mechanical tests like bending test, dripping and drainage test, and fire resistance and corrosion tests, (ii) thermal duty tests, (iii) dielectric power factor tests, (iv) power frequency withstand voltage tests, (v) impulse withstand voltage tests, (vi) partial discharge tests, and (vii) life expectancy tests. Here only the electrical tests are described. Dept. of EEE, NIT-Raichur Page 1 Unit-8 Lecture 52 TESTING OF TRANSFORMERS Transformers are very important and costly apparatus in power systems. Great care has to be exercised to see that the transformers are not damaged due to transient overvoltages of either lightning or power frequency. Hence, overvoltage tests become very important in the testing of transformers. Here, only the overvoltage tests are discussed, and other routine tests like the temperature rise tests, short circuit tests, etc. 3re not included and can be found in the relevent specifications. (a) Induced Overvoltage Test Transformers are tested for overvoltages by exciting the secondary of the transformer from a high frequency a.c. source (100 to 400 Hz) to about twice the rated voltage. This reduces the core saturation and also limits the charging current necessary in large power transformers. The insulation withstand strength can also be checked. (b) Partial Discharge Tests Partial discharge tests on the windings are done to assess the discharge magnitudes and the radio interference levels (see also Sec. 10.6). The transformer is connected in a manner similar to any other equipment (see Sec. 9.4) and the discharge measurements are made. The location of the fault or void is sometimes done by using the travelling wave technique similar to that for cables. So far, no method has been standardized as to where the discharge is to be measured. Multiterminal partial discharge measurements are recommended. Under the application of power frequency voltage, the discharge magnitudes greater than 104 pico coulomb are considered to be severe, and the transformer insulation should be such that the discharge magnitude will be far below this value. Impulse Testing of Transformers The purpose of the impulse tests is to determine the ability of the insulation of the transformers to withstand the transient voltages due to lightning, etc. Since the transients are impulses of short rise time, the voltage distribution along the transformer winding will not be uniform. The equivalent circuit of a transfomer winding for impulses is shown in Fig. 10.11. If an impulse wave is applied to such a network (shown in Fig. 10.11) the voltage distribution along the element will be uneven, and oscillations will be set Dept. of EEE, NIT-Raichur Page 2 Unit-8 Lecture 52 in producing voltages much higher than the applied voltage. Impulse testing of transformers is done using both the full wave and the chopped wave of the standard impulse, produced by a rod gap with a chopping time of 3 to 6 jis. To prevent large overvoltages being induced in the windings not under test, they are short circuited and connected to ground. But the short circuiting reduces theimpedance of the transformer and hence poses problems in adjusting the standard waveshape of the impulse generators. It also reduces the sensitivity of detection. (b) Detection and Location of Fault During Impulse Testing The fault in a transformer insulation is located in impulse tests by any one of the following methods. General observations: The fault can be located by general observations like noise in the tank or smoke or bubbles in breather. Voltage oscillogram method : Fault or failure appears as a partial or complete collapse of the applied voltage wave. Figure 10.14 gives the typical waveform. The sensitivity of this method is low and does not detect faults which occur on less than 5% of the winding. Dept. of EEE, NIT-Raichur Page 3 Unit-8 Lecture 52 Neutral current method : In the neutral current method, a record of the impulse current flowing through a resistive shunt between the neutral and ground point is used for detecting the fault. The neutral current oscillogram consists of a high frequency oscillation, a low frequency disturbance, and a current rise due to reflections from the ground end of the windings. When a fault occurs such as arcing between the turns or from turn to the ground, a train of high frequency pulses similar to that in the front of the impulse current wave are observed in the oscillogram and the waveshape changes. If the fault is local, like a partial discharge, only high frequency oscillations are observed without a change of waveshape. The sensitivity of the method decreases, if other windings not under test are grounded. Transferred surge current method: In this method, the voltage across a resistive shunt connected between the low voltage winding and the ground is used for fault location. A short high frequency discharge oscillation is capacitively transferred at the event of failure and is recorded. Hence, faults at a further distance from the neutral are also clearly located. The waveshape is distorted depending on the location and type of fault, and hence can be more clearly detected. After the location of the fault, the type of fault can be observed by dismantling the winding and looking for charred insulation or melted parts on the copper winding. This is successful in the case of major faults. Local faults or partial discharges are self healing and escape observation. Dept. of EEE, NIT-Raichur Page 4