Complete Guide to Buying a Used Laser

advertisement

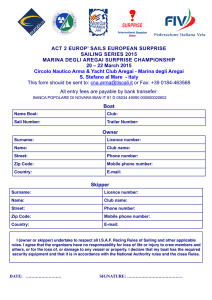

Complete Guide to Buying a Used Laser Written by George Yioulos, 2005 and others on laserforum.org. Edited and enhanced by Russ Hauser, 2007 This guide is intended to be used by someone with little experience with sailing or boats to assess the condition and value of a used Laser sailboat. It does, however, presume a bit of background knowledge of sailboats and Lasers and how they are put together, and the major components. Lasers have been manufactured since the early 1970’s and a boat made 30 years ago can, and does, win competitions with boats a few years old. The major factor is the person sailing – not the boat. All 190,000+ Lasers that have been made are essentially the same and can be sailed and raced against one another as long as they meet basic standards set forth by the manufacturer. When buying (or selling) a used Laser, there are many things to consider. To assess a boat’s condition and value, check each of the following major areas. 1) Serial number and Age • CHECK THE SERIAL NUMBER TO FIND OUT WHEN THE BOAT WAS MADE AND WHERE. Check the transom (rear) of the boat for the serial number. It will look something like PFS 800000779, with the first three letters indicating the builder, followed by a mix of letters and numbers. PFS = Performance Sailcraft (1971-1974) (Montreal, QC); ZFS = Performance Sailcraft (1974 -1985) (Point Claire, QC); PSC = Performance Sailcraft (19??-19??); PSL = Performance Sailcraft USA (San Rafael CA, 1973 to early '80s?); PSI = Performace Sailcraft International (South Africa, until 1989); ZID = Laser International (Hawksbury, ON 1984-1991) Reincarnation of original Laser builder; PSB = Pearson Small Boats (19891991) (Portsmouth, RI) NOTE-Beware of these ones!; SLI = Sunfish Laser Inc (1991 to March 1997)(Portsmouth, RI); OQT = Vanguard Sailboats Inc., (Portsmouth, RI )(March 1997 to present) in SLI facility which Vanguard purchased. Next 5 digits are the Sail Number. If the sail number is greater than 99999, then the first digit is a character, where A=10, B=11, C=12 etc. (i.e. a letter followed by 5 digits). Last 4 characters indicate when the boat was built and the model year. Usually 1 letter followed by 3 numbers. The letter indicates the month of manufacture (according to Sunfish/Laser Inc.): A=Aug, B=Sept, C=Oct, D=Nov, E=Dec, F=Jan, G=Feb, H=Mar, I=April, J=May, K=June, L=July. The next number indicates the year the boat was built (not model year!), followed by a 2 number model year. Eg. D494 = Built Nov, 1994 for 1994 model year For example: SLI F1234 F494 = Sunfish Laser Inc, Sail number 151234, Built in Jan. 94 for Model Year 1994. Older lasers: 1971 to 1973 Hulls: Sail number is found only on the deck under the bow eye. It is reported that following the prototypes, the first production Laser was Number 101. 2) Deck & Hull Condition, Stiffness and Leaks Over its lifetime, a Laser hull will acquire scratches, nicks and dings primarily in the gel coat layer, which effectively makes up the entire outside of the boat. As long as the fiberglass below the gel coat isn’t exposed or damaged (it has a different texture and is a millimeter or two under the gel coat), don’t worry about cosmetics. • CHECK THE ENTIRE HULL AND DECK FOR DEEP SCRATCHES AND EXPOSED FIBREGLASS OR DAMAGE. Gel coat scratches and markings can be wet-sanded out with 600-800-1200 grit sandpaper in a few minutes with haste or an afternoon if you want to make the boat shine. Sealing up small gel coat chips is fairly easy. Your local Laser dealer can match the color, but if you look at the Lasers around, any color will do for most small repairs. While a nicely sanded and fair look is easy on the eyes, it really doesn’t affect the value much at all. You do want to watch for fiberglass damage. Discoloration or fading is a sign of UV damage. The Laser stands up to UV rays pretty well, but a long time in the sun will eventually damage the appearance, and the materials that make up the hull and deck. • CHECK THE DECK AND HULL FOR STIFFNESS. Push down on either side of cockpit. Push firmly -- your body weight will rest here while sailing. Does the deck flex when you push it? Yes, no, maybe so? Maybe a lot, or maybe it’s nice and firm? Do the same test around the cockpit floor and around the mast step. The stiffness of a Laser’s deck & hull is akin to a car’s odometer. The deck and hull stiffness can give you a general understanding of condition and previous use and care. A boat can lie somewhere between ‘stiff’ or ‘soft’. A new boat is very stiff, and this stiffness decreases with general use and having water inside the boat. A stiff boat will resist your pushing into the deck and hull with your hands while a soft boat will give and flex. Softness can come with age and leaks, or with aggressive sailing by someone who races the boat and pushes it in strong winds which can lead to small cracks in the fiberglass exterior and interior structure. These cracks seep water into the hull. The deck is a sandwich of foam between fiberglass layers with gel coat on the top. When it's all stuck together this is really stiff but the fiberglass can delaminate from the foam, which is one reason it will move or flex. Depending on what you felt, you have just gauged the relative integrity of the hull. You have some idea of the stiffness and current integrity. You simply may not require a stiff hull if you’re planning on some casual sailing. A stiff boat will obviously be worth more and will continue to hold its value better than a boat that is becoming softer and softer. But knowing what a softer boat means, in terms of general condition, can help you make an educated decision about what boat is right for you. Deck and hull stiffness is important, but it’s just the one part of the equation – you need to balance all aspects to decide if this boat and price are right for you. A softer boat will probably have some leaks. • CHECK FOR WATER IN THE HULL BY OPENING THE TRANSOM DRAIN PLUG AND LIFTING THE BOW. Absence of water doesn't mean it doesn't leak, but if water gushes out you might want to know why. It's tough to check for leaks unless you can sail the boat. There are many articles online on how to search out these leaks and try to repair them, but you’ll never get back the original stiffness in the boat. • IF POSSIBLE, CHECK THE WEIGHT OF THE HULL. A new hull weighs about 130 pounds. Don't necessarily look for a light boat -- you are sacrificing stiffness and durability for an insignificant gain in speed. However you probably don't want a 150 lb Laser. From here on out is a personal value decision about what you need from the boat, and for that you should consider the other items on this list. 3) Mast Step The mast step is a key component of a Laser and this structure bears much of the stress from the mast and sail. It’s expensive and time-consuming to fix (up to $400 US) -- but easy to check. If the mast step leaks, water gets into the hull aggravating the deck and hull integrity issue from point #2 above. • CHECK THE MAST STEP AND TUBE FOR CRACKS, WEAR AND LEAKS. Look for spider cracks around the deck opening to the step. Look for wear on the inside of the mast tube. If you can, an easy way to check for leaks is to fill the tube with water. Wait 5 minutes. If it isn’t full, it’s leaking into the boat. If you see an inspection port right next to the step (4”-5” disc that can be opened to gain access to the inside of the boat for repairs or storage), the step may have been repaired or replaced already. 4) Kit (SAIL, SPARS, BLADES & UPGRADES) • CHECK SAIL AND LINES FOR WEAR AND DAMAGE. A good sail is very important. You might not need a new sail, but a tired and worn sail will just steepen your learning curve. Because the material in all Laser sails is ‘stretchy’, it loses its shape over a period of use. This means an old sail is less efficient, harder to de-power and harder to trim into proper shape. Even if you aren’t intending to go as fast as possible, you don’t want a car designed for a V-8 engine running on only five cylinders! Make sure you get a boat with a good sail. A new class legal sail costs around $600, but training sails can be bought for less than $200 (they work just as well and last longer). CHECK THE SAIL FOR THE RED LASER PATCH NEAR THE TACK. As of 2010 the only class legal sailmakers in the world are North and Hyde. If the sail is a rag you'll have to buy one anyway if you plan to race in a sanctioned event, but clubs like SPOG do not care. CHECK THE LINES AND ASSOCIATED GEAR. If the lines are worn or frayed, you'll probably need to replace them ($100-150). If you race, then you'll need a bailer and decent tiller and extension. You may also want an anti-friction plate (~$10) to drop in the mast step. • CHECK THE TWO MAST SECTIONS FOR STRAIGHTNESS AND CORROSION. There are three spars on a Laser; the top and bottom mast sections, and the boom. The spars are made of aluminum and are rather flexible. You want them nice and straight. They can definitely become permanently bent. Sight down the length as you would a 2 x 4 of lumber. Or roll the top section on a flat surface to see if it has a slight bend at the collar. If the boat has been in salt water, inspect the rivets on the spars that hold the plastic and metal fittings in place. Corrosion is pretty easy to see, but it’s hard to accurately tell how much damage has occurred below the surface without drilling out. • CHECK THE BOOM FOR STRAIGHTNESS. It's nice if the boom is straight, but it may have a slight downward bend in it at the vang key. Don't worry about loose fittings too much. You can always rivet those back on or through bolt them. • If you're going to race, CHECK THE MAST RAKE. Put the bottom section (make sure it's not bent) in the mast step. Hook the end of your measuring tape on the back of the top of the top section and measure to the center of the transom. It should be around 12'-6 1/2". The mast rake is hearsay -- the manufacturer's technical specification is not published. There are probably boats which are different and go fast. Check the mast rake especially if the mast step has been replaced. • CHECK THE DAGGERBOARD AND RUDDER. Warped, rough or chipped BLADES are slow. The daggerboard can easily warp or chip at the edges if not treated with basic care. Site the trailing edge of the daggerboard for large variations from straight. The rudder can have stress at the head where the rudder head bolts through. That said, rough blades aren’t difficult to smooth out--little nicks and gouges can often be wet sanded out with 600/800/1200 grit sandpaper. Big nicks or gouges will require gel coat repairs. A warped board may be straightened by heating. New boards are quite expensive ($200-400). New Lasers have some UPGRADED controls: added blocks and improved fittings for the boom vang, outhaul and Cunningham. This started in 2001. New boats come with these new items, and many boats have been retrofitted by now. These new controls make it easier to control and fine-tune the Laser. The boat doesn’t go any faster with them, but it’s simpler and more intuitive. You can also de-power the boat more easily, which is important. 5) General Appearance and Care Has the boat been well cared for and stored properly? A Laser should not be stored or transported on the hull or deck. The strongest part is the outside edge where the hull and deck meet, so the boat should be stored suspended under the gunwales or resting on its side on a gunwale. Transporting or storing the boat can create weakness or soft spots and affect hull or deck strength, shape, and integrity. While hull cosmetics aren’t that important for sailing, the way the boat was cared for and stored can affect overall price. A well cared for and properly stored boat is what you’re looking for. 6) Extras • DOES THE BOAT COME WITH EXTRAS SUCH AS A DOLLY, TRAILER, GEAR BAG, COVERS, CARBON TILLER? Extra parts that make it easy for someone to buy a boat and get right to sailing are valuable. Are a launching dolly, boat cover, or gear bag included? This isn't critical to the die-hard racers, as they typically like everything a specific way. For casual sailors, or anyone just getting into the Laser, being able to hit the water with the right kit is nice. No need to order parts or buy new gizmos. To the water with that boat! Finally never forget the value of the Laser itself. There are fleets of Lasers everywhere. Lots of sailors who race their boats are willing to teach. There are accessories and extras to make sailing fast, fun, exciting, safe and easy. While it’s impossible and probably not necessary to put a monetary component on the fact that the Laser is a ton of fun, it’s another piece of the puzzle of getting into the best and one of the most popular single person small sailboats.