Aqueous Solution-based Inorganic Thin Film - CSMC-MSI

advertisement

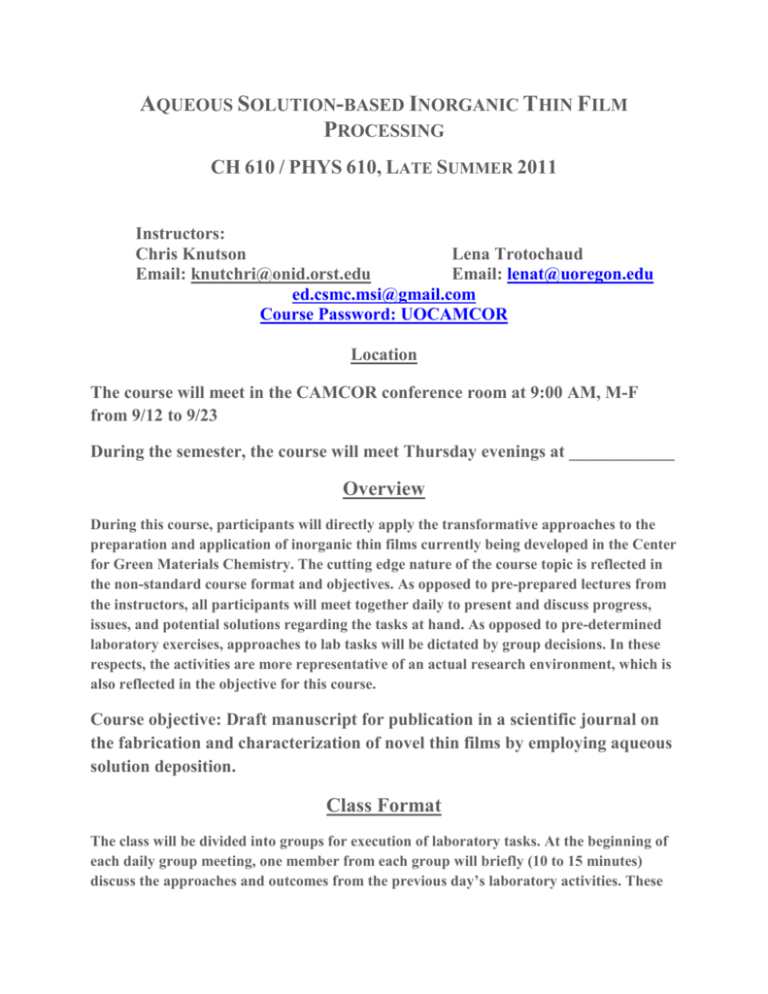

AQUEOUS SOLUTION-BASED INORGANIC THIN FILM PROCESSING CH 610 / PHYS 610, LATE SUMMER 2011 Instructors: Chris Knutson Lena Trotochaud Email: knutchri@onid.orst.edu Email: lenat@uoregon.edu ed.csmc.msi@gmail.com Course Password: UOCAMCOR Location The course will meet in the CAMCOR conference room at 9:00 AM, M-F from 9/12 to 9/23 During the semester, the course will meet Thursday evenings at ____________ Overview During this course, participants will directly apply the transformative approaches to the preparation and application of inorganic thin films currently being developed in the Center for Green Materials Chemistry. The cutting edge nature of the course topic is reflected in the non-standard course format and objectives. As opposed to pre-prepared lectures from the instructors, all participants will meet together daily to present and discuss progress, issues, and potential solutions regarding the tasks at hand. As opposed to pre-determined laboratory exercises, approaches to lab tasks will be dictated by group decisions. In these respects, the activities are more representative of an actual research environment, which is also reflected in the objective for this course. Course objective: Draft manuscript for publication in a scientific journal on the fabrication and characterization of novel thin films by employing aqueous solution deposition. Class Format The class will be divided into groups for execution of laboratory tasks. At the beginning of each daily group meeting, one member from each group will briefly (10 to 15 minutes) discuss the approaches and outcomes from the previous day’s laboratory activities. These presentations will be followed by group discussion to stimulate ideas for problem solving as well as plans for that afternoon’s laboratory tasks. Participants will be expected to independently generate solutions to challenges encountered during the execution of the project. This will invariably involve the design and implementation of systematic experiments to test solutions to processing challenges, as well independent study of relevant literature. Class Project This year’s class is organized around generating tungsten oxide films from an environmentally benign method of dissolving tungsten. We will be generating new thin films via the new methods being developed by the center. We will thoroughly characterize the films produced and test some possible applications of the films. Key Literature [1] A. Telecky, P. Xie, J. Stowers, A. Grenville, B. Smith, and D. A. Keszler, “Photopatternable inorganic hardmask,” Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures, vol. 28, no. 6, p. C6S19, 2010. [2] K. Jiang, J. T. Anderson, K. Hoshino, D. Li, J. F. Wager, and D. A. Keszler, “Low-Energy Path to Dense HfO2 Thin Films with Aqueous Precursor,” Chemistry of Materials, vol. 23, no. 4, pp. 945-952, Jan. 2011. [3] H. F. Okorn-Schmidt, “Characterization of silicon surface preparation processes for advanced gate dielectrics,” IBM Journal of Research and Development, vol. 43, no. 3, pp. 351-365, 1999. [4] Z. L. Mensinger, J. T. Gatlin, S. T. Meyers, L. N. Zakharov, D. A. Keszler, and D. W. Johnson, “Synthesis of Heterometallic Group 13 Nanoclusters and Inks for Oxide Thin-Film Transistors,” Angewandte Chemie, vol. 120, no. 49, pp. 9626-9628, Nov. 2008. [5] J. T. Anderson et al., “Solution-Processed HafSOx and ZircSOx Inorganic Thin-Film Dielectrics and Nanolaminates,” Advanced Functional Materials, vol. 17, no. 13, pp. 21172124, Sep. 2007. [6] S. T. Meyers, J. T. Anderson, D. Hong, C. M. Hung, J. F. Wager, and D. A. Keszler, “Solution-Processed Aluminum Oxide Phosphate Thin-Film Dielectrics,” Chemistry of Materials, vol. 19, no. 16, pp. 4023-4029, Aug. 2007. Suggested Reading 1. Mitzi, D. B. Solution Processing of Inorganic Materials; Wiley: Hoboken, New Jersey, 2009. 2. D.C. Johnson, D.W. Johnson, J.F. Wager, and D.A Keszler, “Green Semiconductor Manufacturing – Potential New Routes Using Aqueous Solution Chemistry,” Proceedings of the CS MANTECH Conference, May 17th-20th, 2010, Portland, Oregon, USA. Day Topic 9-12 9-13 9-14 9-15 9-16 9-19 9-20 9-21 9-22 Assigned Primary Lab Tasks Reading Common devices and current materials [1], processing: [2] Wafer preparation Deposition CAMCOR capabilities Guest speaker: Dr. Dave Johnson Photopatterning oxide materials, and the [3] effect on device sizes Guest speaker: Alan Telecky Discussion: Best practice methods for preparing wafers Discussion: Early findings about films and deposition Discussion: Characterization Techniques Presentations Discussion: Other methods of generating clusters in solution Discussion: Non-thickness data generation and presentation Discussion: Writing [4] [5] [6] 9-23 9-26 Discussion: Writing 9-27 9-28 Discussion: Writing 9-29 9-30 Final Exam 10-1 until the end of semester Group Meetings Assignments Form Teams Assess equipment & chemicals Attain Training X-ray certification Standardization of reagents Generation of solution precursors Standardizing wafer preparation Initial depositions of films Generate thickness vs. molar concentration curves for designated molarities Tech transfer Make sure each group’s curves are within tolerance of eachother Standardize until thickness characterization is congruent Collect non-thickness data Work up data collected A draft of paper in submission Find literature examples: o good figures o bad figures Find literature examples: Group VI peroxide complexes Transition metal peroxide complexes Read and mark classgenerated paper Chemical ordering assignment Pick a characterization technique to present to the class in 10-15 slides o Presentations are on Friday 9/16 Generate Recipes for specific molarities of solutions Generate first solutions and samples Get certification on pertinent equipment Do your reading, there will be a quiz on 9-26 Thickness vs. concentration profiles DUE 9/23 Start Google Document Begin writing o organize bibliographic management o choose format & journal o Compile data Collect nonthickness data Work up data collected Continue writing o organize bibliographic management o choose format & journal o Compile data o Write Sections Collect data Work up data collected Complete the journalquality contribution.