Work at Height Risk Assessment Checklist

advertisement

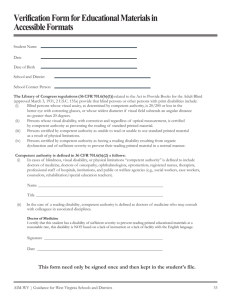

RISK ASSESSMENT WEST LOTHIAN COUNCIL WORK AT HEIGHT RISK ASSESSMENT CHECKLIST SERVICE UNIT: COMPLETED BY: DATE: TASK DESCRIPTION: Key Boxes coloured grey must have a YES answer √ Appropriate box Yes 1 1.1 2. Can work at height be avoided? No N/A Advice/Comment If YES there is no need to continue Plan and Organise 2.1 2.2 2.3 2.4 2.5 3. Has the work been properly planned? It is being appropriately supervised? Have you planned for emergencies and rescue? Have you undertaken a risk assessment for the work? Does the risk assessment take into account young persons? Weather 3.1 4. 4.1 4.2 Will you postpone the work if weather conditions endanger health and safety? Training Are all personnel involved in the work competent? If personnel are being trained to do the work are they being adequately supervised? 1 Data Label: Internal Justification 4.3 5 5.1 6 Have all personnel who will be working at height been trained in how to avoid falling and how to avoid or minimise injury if they fall? Where Work is Done Have you ensured that the place where the work is to be done at height (including access) is safe and has features to present a fall Equipment Choice 6.1 Does the work equipment prevent a fall? 6.2 Does the equipment minimise the distance and consequence of a fall? Schedule 1 conditions must be satisfied If you cannot ensure that the place where work is done at height is safe and has features to prevent a fall (5.2 above) then, you must provide equipment to prevent a fall. If you cannot do that, you must do all that is reasonably practicable to minimise the distance and effect of a fall. The most suitable equipment will be equipment that gives collective protection priority over personal protection measures If NO you must justify why you have not chosen equipment that would prevent a fall. If NO you must justify why you have not chosen equipment that would minimise the distance and consequence of a fall. 2 Data Label: Internal 6.3 Does the equipment minimise the consequences of a fall? If NO you must justify why you have not chosen equipment that would minimise the consequences of a fall. 6.4 Have you chosen work equipment which does none of the above? Specify what work equipment you will be using. 6.5 Does the equipment choice give collective protection? Collective protection is given priority over personal protection therefore if your answer is NO you must justify why you have not chosen collective protection. 6.6 Does the equipment choice give personal protection? Is the equipment to be used properly maintained and inspected? Inspection 6.7 7 7.1 7.2 Schedules 2,3,4,5,6,7 apply. Is your equipment is dealt with under any of these Schedules you must complete the relevant checklist. Does the equipment you have chosen comply with its relevant Schedule? Will you check, on every occasion, before the place at where work at height takes place before it is used? 3 Data Label: Internal 7.3 7.4 7.5 7.6 7.7 8 Will you ensure any item mentioned in Schedule 206 is inspected after assembly or installation if its safety depends on how it is assembled or installed? Will you make sure any deterioration can be detected and remedied in good time If you use equipment from another business will you make sure it is accompanied by a document, which makes clear the last inspection by these regulations has been carried out? (This applies to equipment that you give to others)? Will you ensur3e any platform for use of access which a person could fall more than 2m is inspected in place before use (and not more than 7 days before use? Have you been given a report giving Schedule 7 details within 24 hours of the inspection of the platform being done? Fragile Surfaces 8.1 Mobile platforms do not need reinspection every time it is moved. An at site inspection is sufficient. You must keep platform reports on site and thereafter for 3 months in your office. Other records of inspection must be kept until the next inspection. If this section is not applicable please mark N/A in the “Justification” box opposite. Have you made sure no-one under your control goes onto or near a fragile surface unless it is safe for the worker to do so? 4 Data Label: Internal 8.2 8.3 If personnel need to go onto or near a fragile surface have you made them aware of the danger If work does take place on or near fragile surfaces have you You must erect fixed warning notices at approaches to the danger zone. Ensured that suitable platforms, coverings, guard rails etc are provided to minimise the risk 8.4 If the risk of a fall still exists after putting in place suitable equipment have you Minimised the distance and effect of the fall 9 9.1 9.2 Falling Objects Have you ensured non-one can bee injured by anything falling? If you cannot ensure that injury by falling objects is eliminated have you Ensured that the area is clearly indicated and that unauthorised people are unable to reach it 5 Data Label: Internal SCHEDULE 1 Existing Places of Work, Means of Access or Egress At Height Are/have they 1.1 1.2 1.3 1.4 1.5 1.6 Stable, have sufficient strength and rigidity for purpose? Resting on a stable and sufficiently strong surface? Sufficient in dimension for safe passage of persons, use of plant or materials required to be used and provide a safe working area in relation to the work to be carried out? Suitable and sufficient means for preventing a fall? A surface that has no gap, which would allow a person to fall through or material or object to fall through and injure a person or present a risk of injury to anyone unless measures have been taken to protect persons against such a risk? Constructed, used and maintained in a condition so as to prevent so far as is reasonably practicable slipping or tripping or being caught between it and an adjacent structure? 6 Data Label: Internal SCHEDULE 2 GUARD-RAILS, TOE-BOARDS, BARRIERS AND SIMILAR COLLECTIVE MEANS OF PROTECTION 2.1 Does the means of protection have 2.1, 2.2, 2.3 – Subject to these sufficient and suitable dimensions, strength there shall be no lateral opening and rigidity for the purpose of use? in the means of protection save 2.2 Is the means of protection placed, secured at a point of access to a ladder or and used to ensure so far as is reasonably stairway where an opening is practicable that they do not become necessary. accidentally displaced? means of protection shall be 2.3 Is the means of protection placed to removed only for the time and to prevent so far as is reasonably practicable the extent necessary to gain a fall or any person, material or object from access or egress or for the any place of work? performance of a particular task and must be replaced as soon as possible. the task must not be performed while the means of protection are removed unless effective compensatory safety measures are in place 2.4 Is the top guard rail or other similar means of protection at least 950mm or, if the protection is already fixed at the coming into force of these Regulations (6.4.05) be at least 910mm above the edge from which a person is liable to fall? 2.5 Are the toe-boards suitable and sufficient to prevent the fall of any person, material or object from any place of work? 2.6 Are intermediate guard-rails or similar means of protection position so that any gap between it and other means of protection does not exceed 470mm? 7 Data Label: Internal 2.7 If any structure or part of a structure which supports a means of protection or to which a means of protection is attached of sufficient strength and suitable for the purpose of support or attachment? 8 Data Label: Internal SCHEDULE 3 3.1 SURFACE CONDITION Is the surface which supports the structure stable, have sufficient strength and of suitable composition to support the supporting structure, the working platform and any load intended to be put on the working platform? 3.2 WORKING PLATFORMS Supporting structure definition – Any structure used to support a working platform and includes any plant used for that purpose. STABILITY OF SUPPORTING STRUCTURE Is the supporting structure suitable, strong and ridged enough for its use? If it is a wheeled structure, is it prevented by appropriate devices from moving inadvertently during work at height? Is it prevented from slipping by being secured to the bearing surface or to another structure, by provision of an effective anti-slip device or by another means, which is as effective? Will it be stable when being erected, used and dismantled? Will it remain stable when altered or modified? 3.3 STABILITY OF WORKING PLATFORM Is it suitable, strong and ridged enough for its use? Will it be erected and used to ensure its components do not become accidentally displaced as to endanger any person? 9 Data Label: Internal If you alter or modify it will you ensure that it remains stable? Will it be dismantled in a way to prevent accidental displacement? 3.4 SAFETY ON WORKING PLATFORMS Do they have sufficient dimensions to allow safe passage of persons and safe use of any plant or materials required to be used and provide a safe working area with regard to the work being carried out? Does it have a suitable surface and is it constructed so that the surface of the platform has no gap through which a person could fall or through which any material or object could fall and injure a person? If the platform surface and the construction of that surface gives rise to another risk of injury to any person other than that mentioned above have all necessary measures been taken to protect persons against the risk? Are the working platforms erected, used and maintained in a condition that will prevent slipping or tripping or a person being caught between the working platform and any adjacent structure? 3.5 LOADING Have you made sure that working platforms and any supporting structure is not loaded so that it would give rise to a risk of collapse or to any deformation which could affect its safe use? 10 Data Label: Internal 3.6 ADDITIONAL REQUIREMENTS FOR SCAFFOLDING If the scaffold assembly does not conform with a generally recognised standard configuration or if you do not have available a note of the calculations covering the structural arrangements contemplated have you made sure that strength and stability calculations for the scaffold has been carried out? If the scaffold selected is complex, has a competent person drawn up an assembly, use and dismantling plan? The plan can be in the form of a standard plan, supplemented by items relating to specific details of the scaffolding in question. Is there a copy of that plan, including any instructions kept available for the use of persons concerned in the assembly, use, dismantling of alteration of scaffold until it has been dismantled? Are the dimensions, form and layout of scaffolding decks appropriate to the nature of the work to be performed and suitable for the loads to be carried and will they allow work and passage safely? 11 Data Label: Internal Has scaffold that is not available for use, including during its assembly, dismantling or alteration marked with general warning signs in accordance with the Health and Safety (Safety Signs and Signals) Regulations 1996 and has suitable physical means to prevent access to the danger zone been put in place? Is the scaffolding assembled, dismantled or significantly altered by a competent person or under the supervision of a competent person and by persons who have received appropriate and specific training in the operations envisaged which addresses specific risks that the operations could entail and the precautions to be taken? Do these competent persons or persons under supervision of a competent person who have received appropriate and specific training as specified above understand the plan for the assembly, dismantling or alterati8on of scaffold? 12 Data Label: Internal Do these competent persons or persons under supervision of a competent person who have received appropriate and specific training as specified above take in to account safety during the assembly, dismantling or alteration of the scaffolding concerned? Do these competent persons or persons under supervision of a competent person who have received appropriate and specific training as specified above take measures to prevent the risk of persons, materials or objects falling Do these competent persons or persons under supervision of a competent person who have received appropriate and specific training as specified above understand the safety measures required in the event of changing weather conditions that could adversely affect the safety of the scaffold in concerned? Do these competent persons or persons under supervision of a competent person who have received appropriate and specific training as specified above know the permissible loadings 13 Data Label: Internal SCHEDULE 4 4.1 4.2 4.3 4.4 4.4 4.5 COLLECTIVE SAFEGUARDS FOR ARRESTING FALLS Can you demonstrate that the work activity can be done safely using this safeguard without affecting its effectiveness? Demonstrate this in the last column If you cannot answer yes then you cannot use this type of safeguard. Can you demonstrate that safer work equipment cannot be used? Demonstrate this in the last column If you cannot answer yes then you cannot use this type of safeguard. Can you demonstrate that a sufficient number of available persons have received adequate training specific to the safeguard, including rescue procedures? Demonstrate this in the last column If you cannot answer yes then you cannot use this type of safeguard. Will the safeguard to suitable ad of sufficient strength to arrest safely the fall of the person who is liable to fall? If the safeguard designed to be attached, can it be securely attached to all the required anchors? Are the anchors and means of attachment of suitable and sufficient strength and stability for the purpose of safely supporting the likely loading in arresting any fall and during any rescue? If the safeguard is an airbag, landing mat or similar is it stable? If the safeguard is one that distorts in arresting a fall does it give sufficient clearance? 14 Data Label: Internal 4.6 Have you taken suitable and sufficient steps to ensure that in the event of a fall the safeguard itself does not cause injury to the person who falls? SCHEDULE 5 PERSONAL FALL PROTECTION SYSTEMS 5.1 Can you demonstrate that the work can be performed safely while using the system chosen? Demonstrate this in the last column If you cannot answer yes then you cannot use this type of safeguard. 5.2 Can you demonstrate that the use of other safer work equipment is not reasonably practicable? Demonstrate this in the last column If you cannot answer yes then you cannot use this type of safeguard. 5.3 Can you demonstrate that the user and a sufficient number of available persons have received adequate training specific to the operations to be undertaken, including rescue procedures? If the personal fall protection system suitable and sufficient in strength for the task and the loading? Does the personal fall protection system fit the user? Can the personal fall protection system be correctly fitted? Is the personal fall protection system designed to minimise injury to the user and can it be adjusted to prevent the user falling or slipping from it? Demonstrate this in the last column If you cannot answer yes then you cannot use this type of safeguard. 5.4 5.5 5.6 5.7 15 Data Label: Internal 5.8 5.9 5.10 5.11 5.12 5.13 Has the personal fall protection system been designed, installed and used to prevent unplanned or uncontrolled movement of the user? If the system is designed for used with an anchor is it securely attached to at least one anchor? Is each anchor and the means of attachment of suitable and sufficient strength and stability for the task of supporting the load? ADDITIONAL REQUIREMENTS FOR WORK POSITIONING SYSTEMS Is there a suitable backup system for preventing or arresting a fall? If the system includes a line as a backup system, which the user is connected to, or there is no reasonably practicable way to comply with having a suitable back system have you taken all measures to ensure that the work positioning system does not fall? ROPE ACCESS AND POSITIONING TECHNIQUES If the system comprises at least 2 separately anchored lines, of which one ie the working line, is used as access, egress and support and the other is the safety line has a suitable harness connected to the working line and safety line been provided to the user? 16 Data Label: Internal 5.14 5.15 5.16 If the system comprises at least 2 separately anchored lines, of which one ie the working line, is used as access, egress and support and the other is the safety line, is the working line equipped with a safe means of ascent and descent with self locking system to prevent the use falling if there is a loss of control? If the system comprises at least 2 separately anchored lines, of which one ie the working line, is used as access, egress and support and the other is the safety line is that safety line equipped with a mobile fall protection system connected to and travels with the user of the system? If the system comprises at least 2 separately anchored lines, of which one ie the working line, is used as access, egress and support and the other is the safety line have you taken into account the duration of the job plus the ergonomic constraints which must be made for a seat with appropriate accessories? SINGLE ROPE SYSTEM 5.17 If you are using a system, which has a single rope, can you demonstrate that a second line would make the risk higher to the person? Demonstrate why it would make the risk higher in the last column. 5.18 If using a system which has a single rope have you taken appropriate measures to ensure safety Details what these measures are in the last column. 17 Data Label: Internal FALL ARREST SYSTEMS 5.19 5.20 5.21 Does it have a suitable means of absorbing energy and limiting the forces applied to the user’s body? Can you ensure that it will not be used in a way that would risk the line being cut? Is there a clear zone where its use requires it (allow for any pendulum effect)? WORK RESTRAINT SYSTEM 5.22 5.23 If the work restraint system designed so that when correctly used, it prevents the user from getting into a position in which a fall can occur? Can you ensure that it will be used correctly? SCHEDULE 6 LADDERS 6.1 Can you demonstrate that the use of more suitable work equipment is not justified 6.2 Will the ladder rest on a stable, firm surface that is of sufficient strength and suitable composition to support the ladder so that the rungs or steps remain horizontal and support any loading intended to be placed on it? The work must be Low risk and Duration of use short or there are existing features on site which cannot be altered Demonstrate your justification in the last column. 18 Data Label: Internal 6.3 6.4 6.5 6.6 6.7 6.8 6.9 6.10 Will the ladder be positioned to ensure stability during use? If a suspended ladder will it be attached in a secure manner so that it cannot be displaced and swinging is prevented (exception a flexible ladder)? Will portable ladders be prevented from slipping by securing the stiles at or near the upper or lower ends or; use effective anti-slip or other effective stability device or; use any other arrangement of equivalent effectiveness? If the ladder use for access long enough to protrude sufficiently above the landing place to which it provides access or have you provided other measures to ensure a firm handhold? Are the sections of interlocking or extension ladders prevented from moving relative to each other while in use? Will mobile ladders be prevented from moving before it is stepped on? Have ladders or a run of ladders which rise a vertical distance of 9m or more above its base been provided with sufficient safe landing areas or rest platforms at suitable intervals? Is there a secure handhold and secure support always available to the user? Say which you have done in the last column. 19 Data Label: Internal 6.11 Can the user maintain a safe handhold when carrying a load? A secure handhold must always be maintained, unless maintenance of a handhold is not practicable when carrying a load. Light loads should be carried in a back pack or tool belt. Heavy loads must be lifted or hoisted by the appropriate equipment. 6.12 Can you demonstrate that the use of a stepladder is justified because the risk is low and the use is of short duration Short duration – not more than 15-30 minutes, depending on the task being performed. The person can resume the operation after a suitable break if necessary. Only use step ladders when existing features cannot be altered or other methods cannot be used to avoid the need to work at height. SCHEDULE 7 7.1 REPORT OF INSPECTION PARTICULARS Does the report of inspection have the following particulars Name and address of the person for whom the inspection was carried out? Location of the work equipment inspected? Description of the work equipment inspected? Date and time of the inspection Details of any matter identified that could give rise to a risk to the health or safety of any person? 20 Data Label: Internal Details of any action taken as a result of any matter identified in (matters identified that could give rise to a risk to the health or safety of any person)? Details of any further action considered necessary? Name and position of the person making the report? 21 Data Label: Internal 22 Data Label: Internal