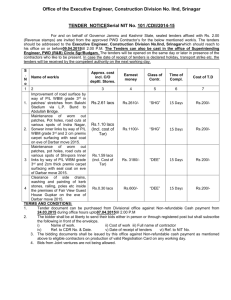

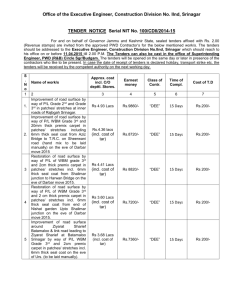

tender document

advertisement