Life cycle indicator comparison of copper, silver, zinc and aluminum

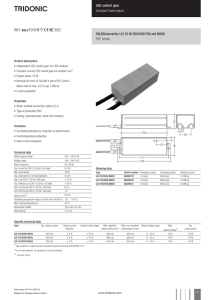

advertisement

Life cycle indicator comparison of copper, silver, zinc and aluminum nanoparticle production through electric arc evaporation or chemical reduction Martin Slottea*, Gregory Methab, Ron Zevenhovena a* Åbo Akademi University, Thermal and Flow Engineering Laboratory Turku, Finland, martin.slotte@abo.fi Åbo Akademi University, Thermal and Flow Engineering Laboratory Turku, Finland, ron.zevenhoven@abo.fi b University of Adelaide, 5005, Department of Chemistry Adelaide, South Australia, Australia, greg.metha@adelaide.edu.au a Appendix H LCI results for nano-particle production using the arc discharge method for different experiments Products marked with “A” and “B” have been produced by University of Duisburg-Essen Germany and Metal Nanopowders Ltd., United Kingdom, respectively. Figure H1 LCI for copper nano-particle production at experimental yields Figure H2 LCI for silver nano-particle production at experimental yields Figure H3 LCI for zinc nano-particle production at experimental yields 2 Figure H4 LCI for aluminum nano-particle production at experimental yields 3