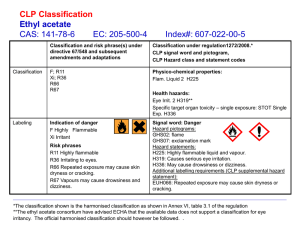

H3.0.0 Flammable liquids

advertisement

Not Protectively Marked Additional Hazard or Information Sheet Flammable Liquids Document Overview Initial information to both inform and assist Incident Commanders when dealing with this subject matter: Incidents involving flammable liquids. 1 Hazards Explosion – Vapours may form explosive mixtures with air. The explosive hazard is enhanced in confined spaces. Flammable vapour – Vapour production is increased when substance is heated or surface area is increased. Most vapours are heavier than air and will spread along ground and collect in low or confined spaces e.g. cellar basements and sewers. Any ignition sources present will provide a flashback. o The majority of flammable liquids do not mix with water and are lighter than water and will therefore “float” on the surface. This will generate more vapour which may be flammable. Boiling Liquid Expanding Vapour Explosion (BLEVE) – Half full or empty containers are more dangerous than full ones as pressure space is greater. Mixture of substances leading to auto-ignition and fire growth– Some flammable liquids, e.g. alcohols will react violently with acids and alkalis, generating large amount of heat and pressure build-up. Oxidising agents will also generate large amount of heat if mixed with a flammable liquid. Toxic/corrosive – Inhalation or contact with material may irritate or burn skin and eyes. Any vapours may be toxic and/or corrosive and may cause dizziness or suffocation. Environmental impact - The chemical structure of flammable liquids are severely damaging to the environment. Substances on their own or part of the fire water run off should be contained if at all possible. Running fuel fire – Ignition of uncontained flowing liquids leading to rapid fire spread/development. Page 1 of 4 NOT PROTECTIVELY MARKED Flammable Liquids 2 Actions Generic actions Consider gas monitoring to determine the extent of the vapour hazard/explosive atmosphere Cordons: Initial cordon 50m Large spill (more than 200ltrs) 300m Fire in tank on road or rail 800m Consider appropriate PPE/RPE/decontamination Un-ignited leak of flammable liquid Once the substance(s) physical properties and environmental impact have been identified, the following actions should be considered: o Eliminate all ignition sources o Stop leak if practicable o Prevent substance entering water courses, drainage systems, basements, etc o Absorb substance with sand, earth or other non-combustible materials o Consider foam suppression of vapours o Consider using water spray to control vapours o Consider water cooling of container/ tank to reduce vapour release o Use intrinsically safe equipment Substance involved in fire 3 Usually easier to deal with but more hazardous: o Use CO2 or dry powder for small fires o Do not directly apply water to burning flammable liquid as this may lead to violent reaction, boil-over or slop-over o Consider using foam, alcohol resistant foam or water spray on large fires o Cool any affected containers with water spray. Tanks or containers involved in fire may over pressurise and explode (BLEVE) Further considerations Beware of flammable liquids entering drains, sewers and other low lying spaces where it may vaporise and create an explosive atmosphere Block drains and contain substance if possible Provide good ventilation to avoid vapour build up Reduce the surface area if possible: o Use of plastic salvage sheet o Foam blanket o Containment Prevent oil substances from contaminating PPE due to fire risk. Use disposable gloves/general purpose gauntlets. Page 2 of 4 NOT PROTECTIVELY MARKED Flammable Liquids 4 Supporting information Some drainage plans have pollution control devices such as penstocks. With permission and planning, such devices can be used by FRSs to prevent pollution to surface and groundwater and to protect sewage treatment works. Flammable liquid hazard warning diamond is shown on the right UN class and ADR Hazard Identification Number (HIN): 3 Described as: 1. Flammable. 2. Highly Flammable. 3. Extremely Flammable. Boiling Liquid Expanding Vapour Explosion (BLEVE) When a container is subjected to heat, especially when heating is due to direct flame contact, expect a BLEVE at any time if adequate cooling is not available. When containers are heated, without adequate cooling, a BLEVE could occur. This is usually a result of the heating of a vessel containing a liquid by an external fire. The contents of the vessel are heated above their boiling point and the pressure in the vessel increases. The failure occurs when the flames impinge on an area which does not have liquid on the other side (dry wall). The vessel ruptures and pieces can be propelled considerable distances. The spillage of the overheated liquids and then ignition create a large fireball with explosion pressure effects. This can mean that it is extremely difficult to predict when, and if, a BLEVE will occur. A vessel that is venting in a fire does not mean that everything is safe, more than likely the opposite is the case. A BLEVE can occur at any time and some have occurred many hours into an incident. Reduction of tank contents may hasten the onset of a BLEVE due to the increase in dry wall area as the tank is emptied. Remember that in the event of a BLEVE the fireball can engulf exposed crew. Page 3 of 4 NOT PROTECTIVELY MARKED Flammable Liquids Document References 1. Relevant References This incident type is potentially linked to the following other operational guidance documents: Document Name Link to Document To be populated 2. Technical References CFRA Fire and Rescue Service Operational Guidance Hazmat Incidents – Part B – Section 7. Emergency Response Guide 2012. Ref no: Date of issue: Version no: Page 4 of 4 H3.0.0 07/10/2014 1 Lead FRS: Review date: Protective marking: NOT PROTECTIVELY MARKED Hampshire 07/10/2017 None